Sulphur resistant carbon monoxide transfer catalyst and preparation thereof

A technology for shifting catalysts and carbon monoxide, which is applied in the field of sulfur-resistant carbon monoxide shifting catalysts and its preparation, which can solve the problems of poor low-temperature activity, decreased activity, and inability of the catalyst to adapt to the operating environment, so as to achieve difficult phase transition, high activity, and good activity stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] 1) Preparation of carrier

[0019] Weigh 1mol of light MgO and Al 2 o 3 1 mol of amorphous hydrous alumina (with a water content of 58%) was placed in a kneader, and a 4% nitric acid aqueous solution was gradually added for mixing and kneading. Control the amount of nitric acid aqueous solution to make the mixture into a plastic body. Finally, put the plastic body on the extruder and extrude the strip. The strip is a cylinder with a diameter of 3.5-4.5cm. Then the strip is dried at 100°C for 4h, and finally calcined at 850°C for 3h to obtain porous MgAl 2 o 4 carrier.

[0020] 2) Configuration of impregnation solution and impregnation of carrier

[0021] Dissolve 6.8g of potassium carbonate, 0.5g of citric acid, 2.79g of cobalt nitrate and 5.1g of ammonium molybdate in 20mL of deionized water, then adjust the pH of the solution to 8.5 with 6mL of 25% concentrated ammonia water, and the final solution volume is 32mL; The concentration of the solution is MoO 3 0.1...

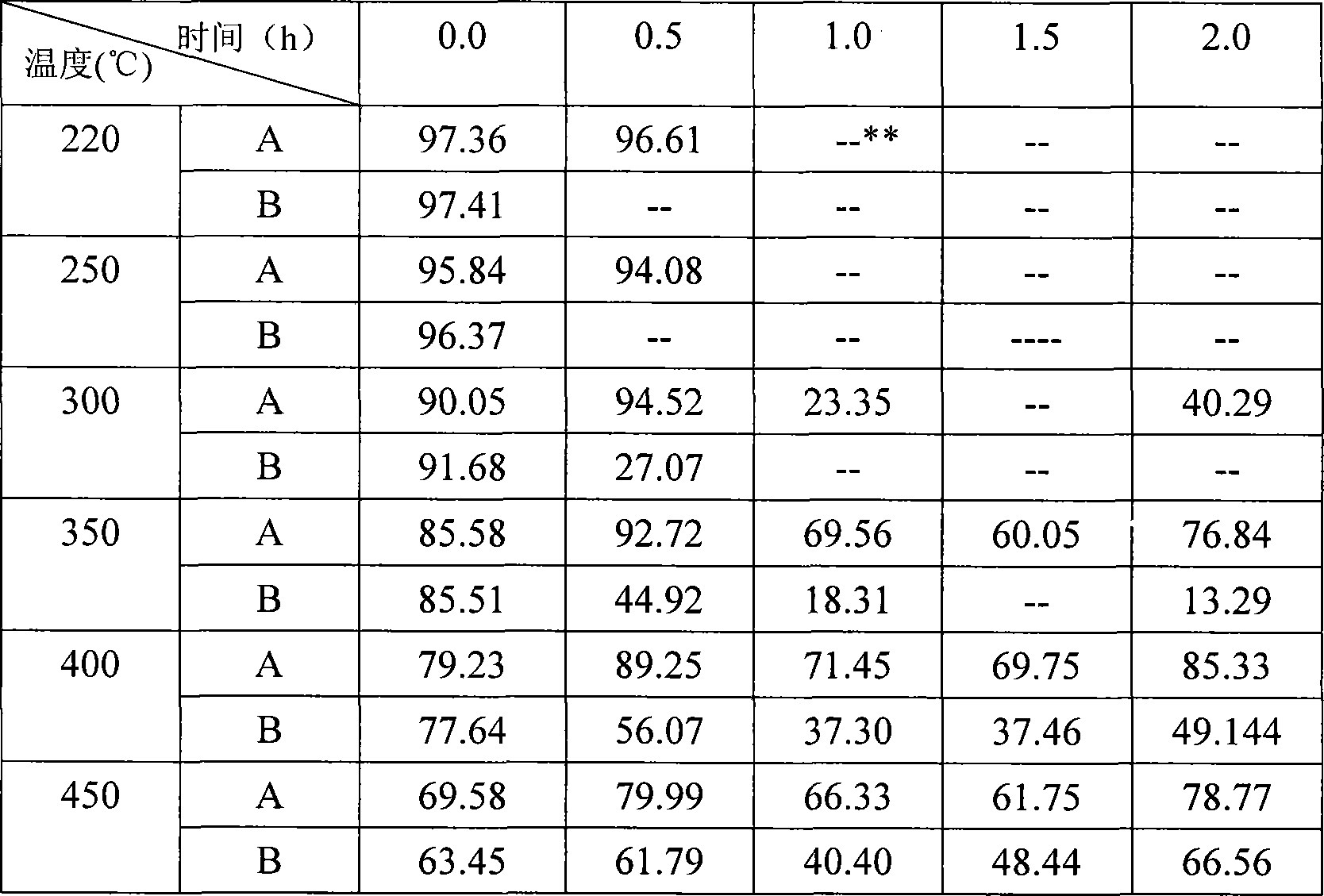

Embodiment 2~4

[0026] Change the potassium carbonate amount in Example 1 into 3.4g, 10.2g, and 13.6g respectively, and all the other are the same as Example 1, namely Examples 2 to 4. The composition and activity evaluation results of the sulfur-resistant carbon monoxide shift catalyst are shown in Table 1.

Embodiment 5,6

[0030] Change the cobalt nitrate amount in embodiment 1 into 0.47g, 4.21g respectively, and all the other are the same as embodiment 1, namely embodiment 5,6. The composition and activity evaluation results of the catalysts are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com