Sulfur-tolerant methanation catalyst and preparation method thereof

A sulfur-resistant methanation and catalyst technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve environmental pollution, nitrogen oxide pollution, and reduce magnesium Problems such as production temperature and production cost of aluminum spinel, achieve high strength and strength stability, and solve the effect of environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

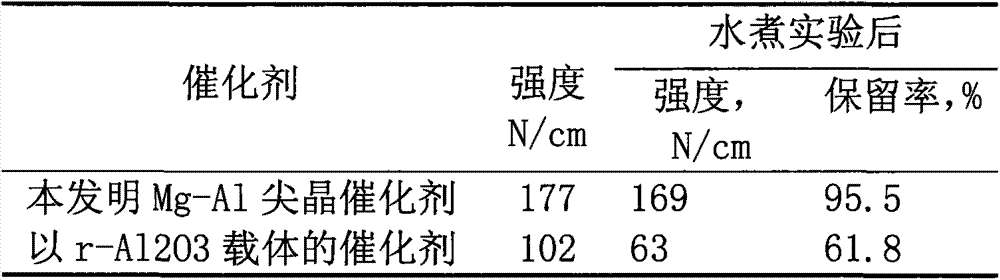

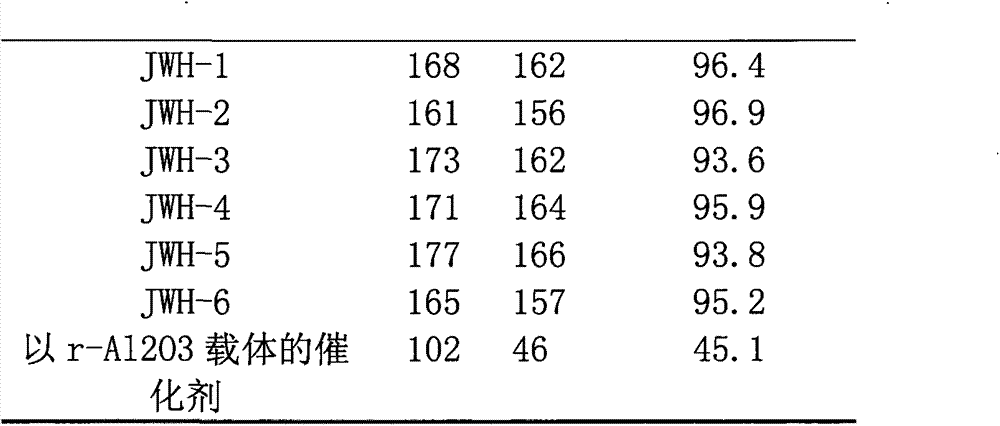

[0025] Take 150 grams of pseudo-boehmite, add MgCO 3 85 grams, add 150ml of water and mix well, dry at 120°C and roast at 600°C for 3 hours to obtain magnesium aluminum spinel masterbatch, use steam to cure the masterbatch for 10-12 hours and then dry to obtain magnesium aluminum spinel stone. Take 100 grams of magnesium aluminum spinel and grind it to 180 mesh, knead it with 10% magnesium nitrate solution, extrude it and roast it at 550° C. for 3 hours to obtain the carrier. Take 100 grams of the carrier, mix 12 grams of ammonium tetramolybdate and 90 grams of cobalt nitrate into a co-impregnation solution, impregnate the carrier with equal volume of the solution, dry and / or roast to obtain the catalyst. The catalyst number is JWH-1. The comparison of its strength and strength stability is shown in Table 2.

Embodiment 2

[0027] The preparation method is the same as in Example 1, and the difference is that MgCO 3 85 grams replaced by 60 grams of Mg(OH) 2 , the catalyst number is JWH-2. Its performance comparison is shown in Table 2.

Embodiment 3

[0029] The preparation method is the same as in Example 1, and the difference is that MgCO 3 85 grams were changed into 42 grams of MgO, and the catalyst number was JWH-3. Its performance comparison is shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com