Construction method of hyperboloidal concrete structure of coal tower storage bunker incline wall

A technology of concrete structure and construction method, which is applied in the field of building construction, can solve the problems that it is difficult to ensure the accuracy of the curved surface and the quality of the concrete, the quality of the concrete pouring is difficult to ensure, and the difficulty of burying the wind vibrating coal pipe is difficult, so as to achieve high pouring quality and precision, The effect of increasing safety and stability, reducing construction difficulty and construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

[0022] A construction method for the inclined wall hyperboloid concrete structure of a coal tower silo, the steps of which are as follows:

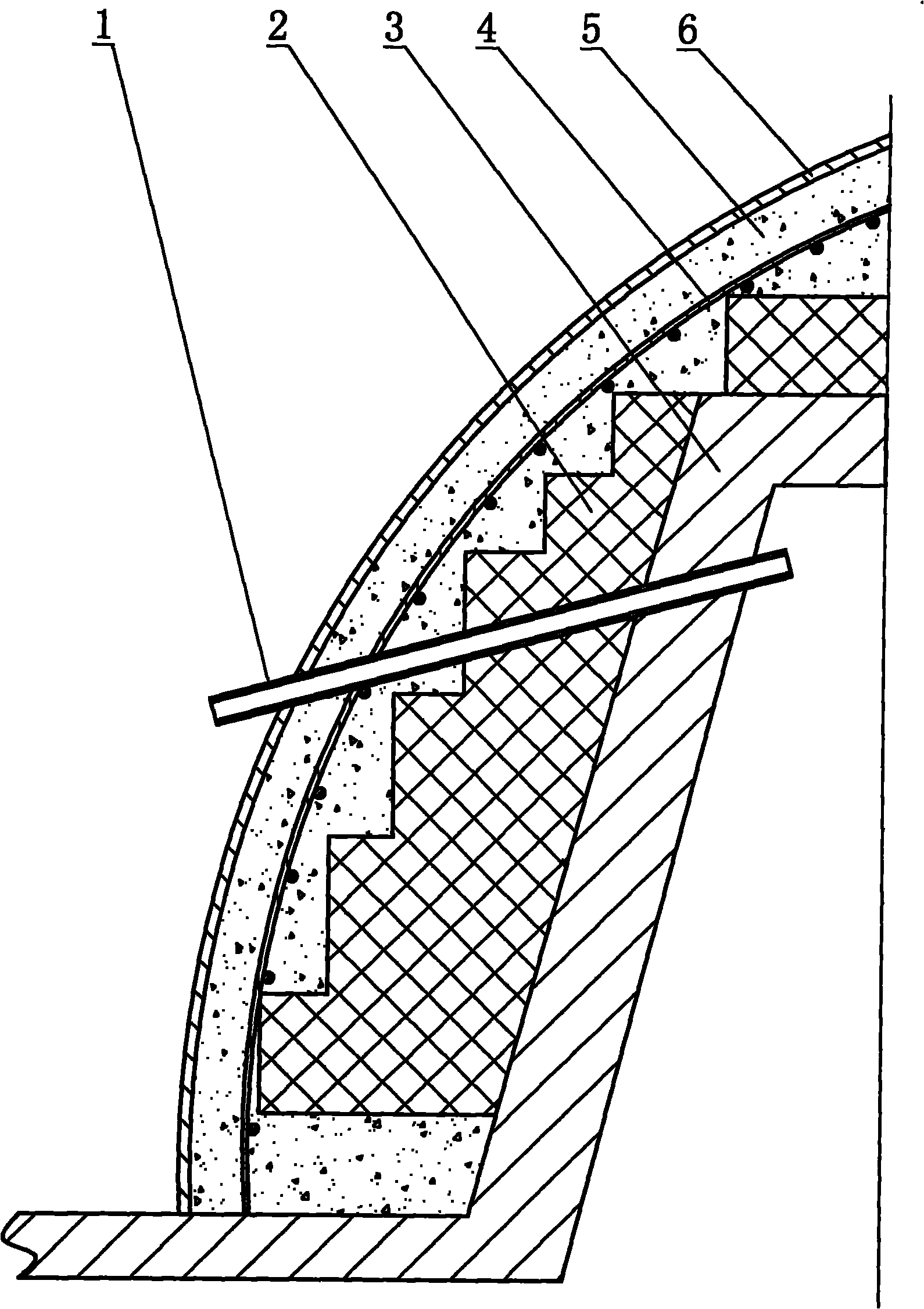

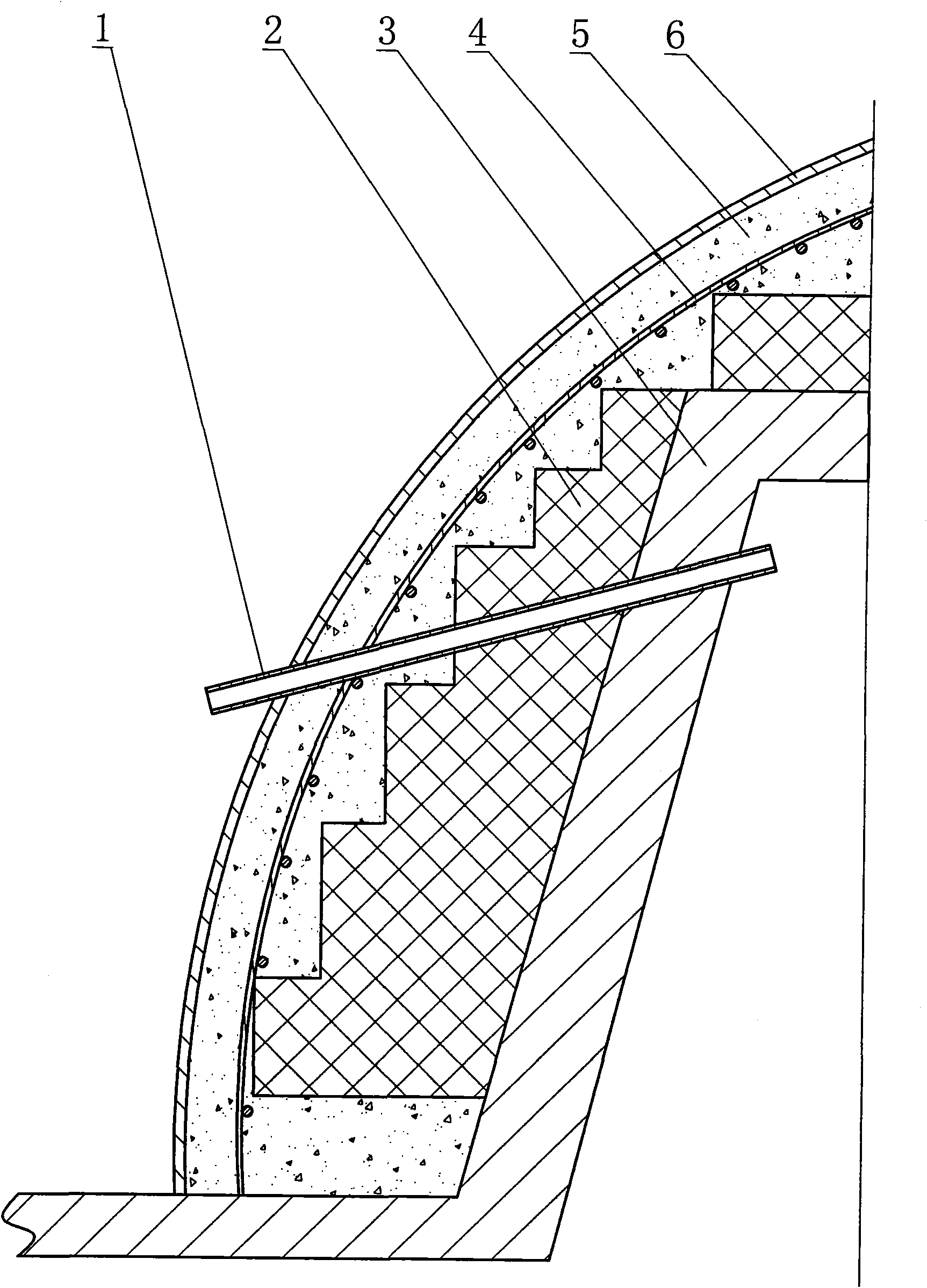

[0023] (1) Build the inclined beam structure 3 of the coal tower silo according to the drawing requirements;

[0024] (2) Aerated concrete blocks 2 are built stepwise from top to bottom close to the slanted beam of the coal tower silo. During the masonry process, the wind-force vibrating coal pipe 1 is buried at the corresponding position, and the surrounding wind-force vibrating coal pipe is buried. Fill it with mortar and use air-entrained concrete blocks to reduce the dead weight without reducing the effective loading capacity of the coal tower; the dead weight of ceramsite concrete in the prior art ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com