Processing technology of 2.5 D Ag glass

A processing technology and glass technology, applied in the field of 2.5DAG glass processing technology, can solve the problems of declining yield and surface AG film damage, and achieve the effects of low cost, fast cleaning and easy promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings. Obviously, the described embodiment is the best embodiment of the present invention.

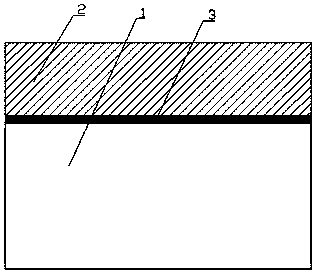

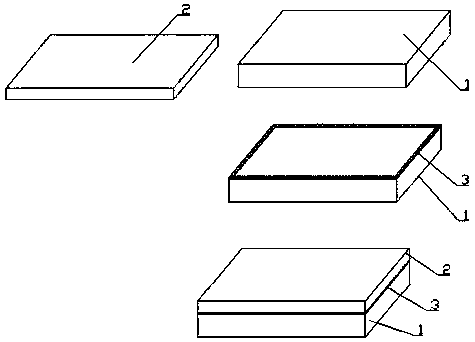

[0035] Such as Figure 1-2 Shown, a kind of 2.5D AG glass processing technique is characterized in that comprising the following steps:

[0036] (1) Cut AG glass and ordinary glass according to the size to obtain equal-sized AG glass substrate 1 and protective glass 2;

[0037] (2) Cleaning and drying the surface of the AG glass substrate 1 prepared in step (1), with the standard that water does not flow or hang on the wall;

[0038] (3) Coating UV hydrolytic glue on the periphery of the AG glass substrate 1 through the dispensing process to form a UV hydrolytic glue layer 3;

[0039] (4) Cover the protective glass 2 prepared in step (1) on the UV hydrolysis adhesive layer 3 to obtain AG glass with a protective layer;

[0040] (5) Put the AG glass with the protective layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com