A kind of organic crosslinking acid system and its preparation method and application

A technology of organic acid and cross-linked acid solution, which is applied in chemical instruments and methods, mining fluids, earthwork drilling and mining, etc. It can solve the problem that the deep penetration of the acidification system cannot be met, the interaction between hydrochloric acid and the formation is fast, and the formation cannot be treated. Deep and other problems, to achieve the effect of long acid etching effective action distance, improve production increase effect, and increase viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

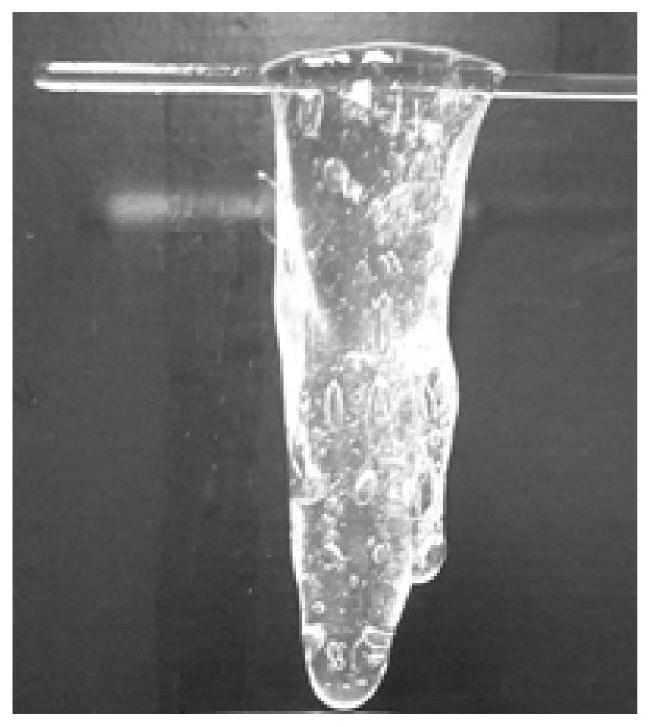

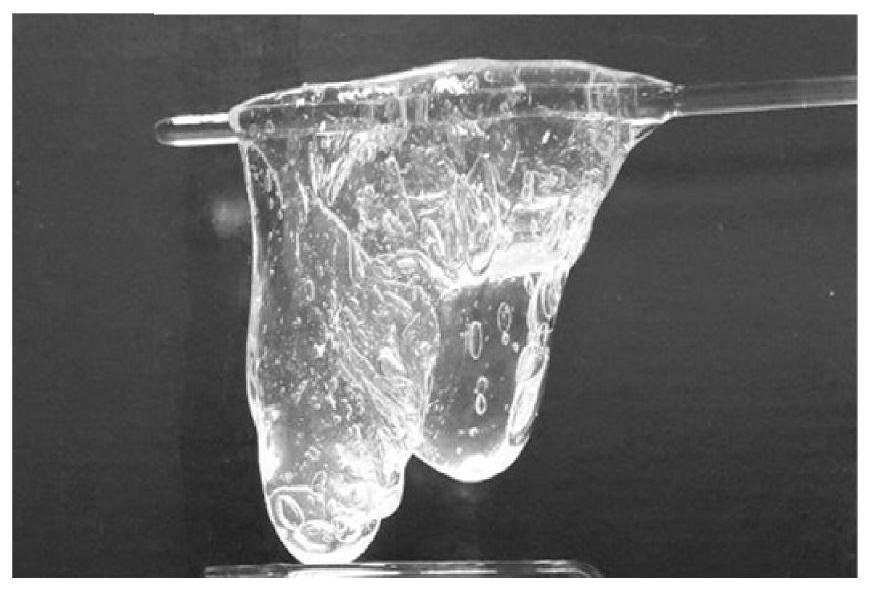

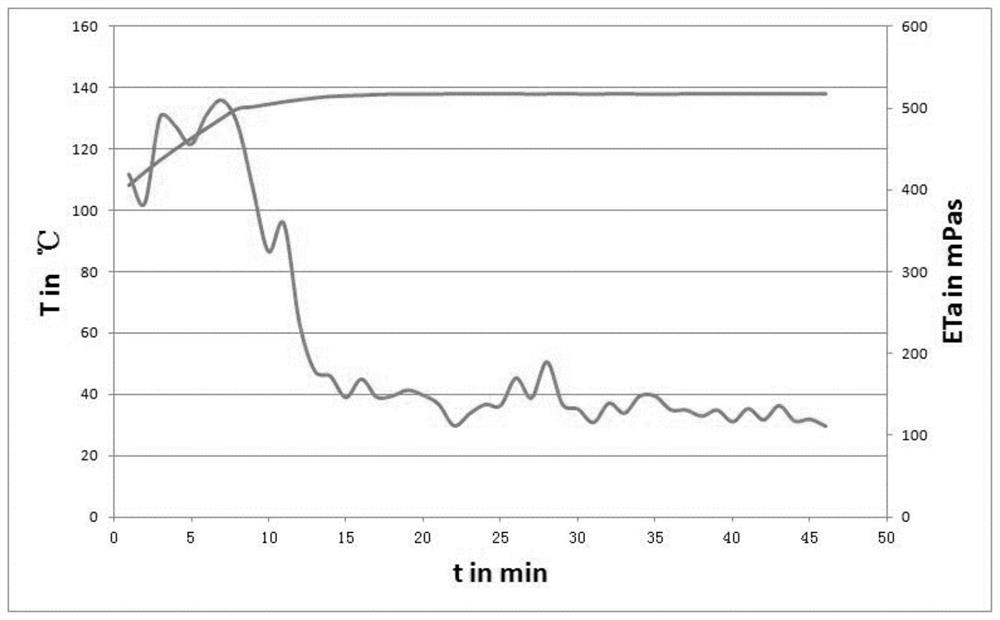

Image

Examples

Embodiment 1

[0035] The components of the organic cross-linking acid liquid system are as follows by mass percentage: concentrated hydrochloric acid 55.6% (equivalent to 20% of pure hydrogen chloride), formic acid 5%, polymer thickener (acrylamide-2-acrylamide-2-methyl propane Sulfonic acid (AMPS) copolymer, molecular weight 8,000,000, monomer molar ratio is acrylamide:2-acrylamido-2-methylpropanesulfonic acid (AMPS)=8:2) 1.0%, organic acid crosslinking agent 1.0 %, the rest is water.

[0036] Preparation of organic crosslinking acid solution:

[0037] (1) Synthesis of organic acid crosslinking agent

[0038] Add 5g of titanium tetrachloride, 50g of isopropanol, and 15g of ethylene glycol into a three-necked flask equipped with stirring and a thermometer, heat to 40°C, and stir at a constant speed of 190r / min for 30min. Add 20g of glycine and 3g of polyepoxysuccinic acid to the above homogeneous solution, heat to 60°C, and stir at 190r / min for 2h; the desired organic acid crosslinking ag...

Embodiment 2

[0043] The composition of the organic cross-linking acid liquid system is as follows by mass percentage: concentrated hydrochloric acid 55.6% (equivalent to 20% of pure hydrogen chloride), acetic acid 5%, polymer thickener 1.0%, organic acid cross-linking agent 1.0%, and the rest is water. The polymer thickener is acrylamide-2-acrylamide-2-methylpropanesulfonic acid (AMPS) copolymer, molecular weight 10 million, monomer molar ratio is acrylamide:2-acrylamide-2- Methylpropanesulfonic acid (AMPS) = 8:2.

[0044] Preparation of organic crosslinking acid liquid system:

[0045] (1) Synthesis of organic acid crosslinking agent

[0046] Add 7g of tetraisopropyl titanate, 30g of isopropanol, and 20g of ethylene glycol into a three-neck flask equipped with a stirring and thermometer, heat to 40°C, and stir at a constant speed of 200r / min for 30min. Add 10g of leucine and 2g of polyepoxysuccinic acid to the above homogeneous solution, heat to 80°C, and stir at 200r / min for 2h to obta...

Embodiment 3

[0051] The organic cross-linking acid liquid system has the following components by mass percentage:

[0052] 55.6% concentrated hydrochloric acid (20% equivalent to pure hydrogen chloride), 5% acetic acid, 7.5% hydrofluoric acid (3% equivalent to pure HF), polymer thickener (acrylamide-methacryloyloxyethyl trimethyl Ammonium chloride copolymer, molecular weight 6,000,000, monomer molar ratio is acrylamide: methacryloyloxyethyltrimethylammonium chloride=10:3) 1.2%, organic acid crosslinking agent (prepared in embodiment 3 ) 1.0%, and the rest is water.

[0053] Preparation of organic crosslinking acid solution:

[0054] (1) Synthesis of organic acid crosslinking agent: Add 4g of titanium nitrate, 20g of isopropanol, and 10g of ethylene glycol into a three-neck flask equipped with a stirring and thermometer, heat to 40°C, and stir at a constant speed of 180r / min for 30min. Add 5g of aspartic acid and 2g of polyepoxysuccinic acid to the above homogeneous solution, heat to 60°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com