Alkali-resistant phosphorus-free chelating agent for pretreatment of cotton knitted fabric, and preparation method thereof

A chelating agent, alkali-resistant technology, applied in fiber treatment, textile and papermaking, plant fiber, etc., can solve the problems of limited sewage discharge, difficult to remove, unfriendly usage scenarios, etc., to achieve automatic control of production and sewage discharge. The effect of reducing the limit and reducing the cost of sewage treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1: S1, add 60g of water to the beaker to construct the water environment, then add 30g of acrylic acid, 10g of methacrylic acid, 10g of sodium methacrylate, 10g of sodium 2-acrylamido-2-methylpropanesulfonate, Stir to dissolve evenly, transfer to No. 1 dropping funnel for later use;

[0033] S2, add 12 parts of water in another beaker to build water environment, 3.5g inorganic peroxide initiator, stirring and dissolving evenly, transfer to No. 2 dropping funnel for subsequent use;

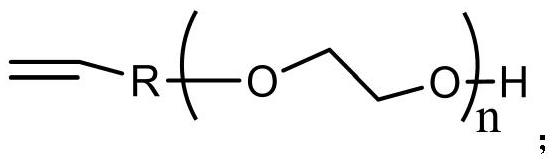

[0034] S3. Add 10g of maleic anhydride and 5g of methallyl polyoxyethylene ether (HPEG-2400 for short, n=60-75) into a 500ML four-neck flask, then raise the temperature to 80°C and keep the temperature and add 50g of water to build a water environment , and then drop the solution in No. 1 dropping funnel and No. 2 dropping funnel respectively, and control the temperature at 80±2°C. The dropping time was controlled at 25 minutes, and after the dropping was completed, the temperature ...

Embodiment 2

[0035] Example 2: S1, add 70g of water to the beaker to construct the water environment, then add 10g of acrylic acid, 5g of methacrylic acid, 5g of sodium methacrylsulfonate, 2g of sodium 2-acrylamido-2-methylpropanesulfonate, Stir to dissolve evenly, transfer to No. 1 dropping funnel for later use;

[0036] S2, add 20 parts of water in another beaker to build water environment, 2g inorganic peroxide initiator, stir and dissolve evenly, transfer to the No. 2 dropping funnel for subsequent use;

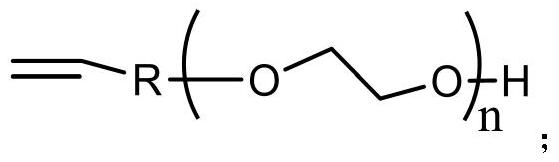

[0037] S3. Add 5g of maleic anhydride and 10g of acryl polyoxyethylene ether to a 500ML four-neck flask, then raise the temperature to 80°C and keep the temperature, add 50g of water to build a water environment, then add dropwise the solution in No. 1 dropping funnel and 2 The solution in the No. dropping funnel, the temperature is controlled at 80±2°C. The dropping time was controlled at 20 minutes, and after the dropping was completed, the temperature was kept for 30 minutes, and ...

Embodiment 3

[0038] Example 3: S1, add 50g of water to the beaker to construct the water environment, then add 40g of acrylic acid, 20g of methacrylic acid, 20g of sodium methacrylate, 20g of sodium 2-acrylamido-2-methylpropanesulfonate, Stir to dissolve evenly, transfer to No. 1 dropping funnel for later use;

[0039] S2, add 10 parts of water in another beaker to build water environment, 5g inorganic peroxide initiator, stir and dissolve evenly, transfer to the No. 2 dropping funnel for subsequent use;

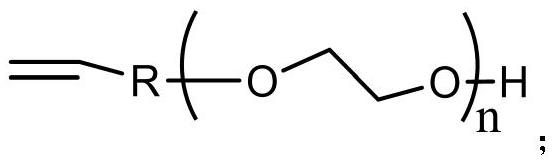

[0040] S3. Add 20g of maleic anhydride and 10g of acryl polyoxyethylene ether to a 500ML four-necked flask, then raise the temperature to 80°C and keep the temperature, add 40g of water to build a water environment, then add dropwise the solution in No. 1 dropping funnel and 2 The solution in the No. dropping funnel, the temperature is controlled at 80±2°C. The dropping time was controlled at 30 minutes, and after the dropping was completed, the temperature was kept for 30 minutes, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com