A kind of oil field neutral scale removing and dispersing agent

A dispersant and neutral technology, applied in scale removal and water softening, complex/solubilizer treatment, mining wastewater treatment, etc., can solve problems such as difficult oilfield sewage treatment, surfactant foam, inconvenient production and use, etc. Achieve the effect of good chemical performance, reduce corrosion and save cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

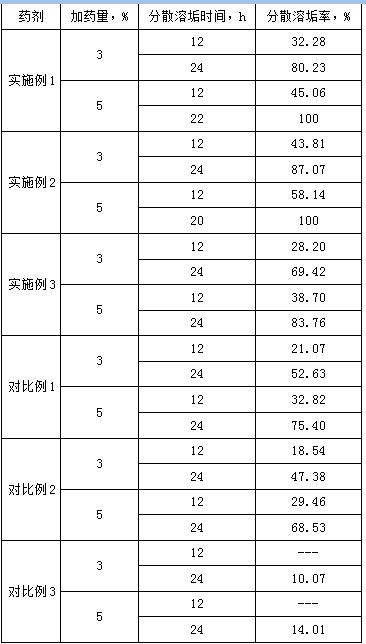

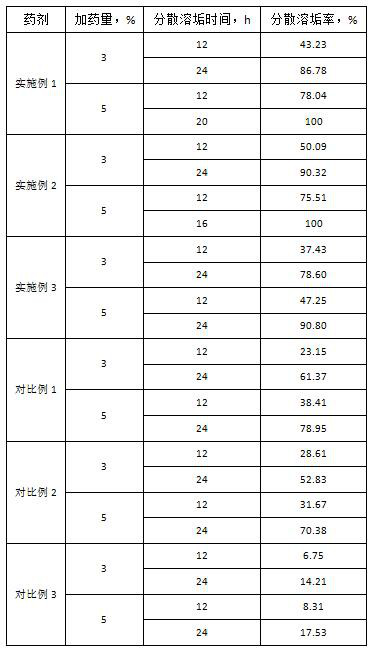

Examples

Embodiment 1

[0021] The first composition of neutral descaling and dispersing agent:

[0022] Hydroxyethylene diphosphonic acid 20 parts

[0023] Acrylic acid-2-acrylamide-2-methylpropanesulfonic acid copolymer 8 parts

[0024] Potassium hydroxide 9.5 parts

[0025] 62.5 parts of deionized water

[0026] The specific preparation process is: add 210g of deionized water, 100g of hydroxyethylidene diphosphonic acid and 40g of acrylic acid-2-acrylamide-2-methylpropanesulfonic acid copolymer into the reaction kettle in sequence, stir evenly, and slowly add hydrogen Oxidize potassium and control the system temperature to ≤70°C, adjust the pH value of the system to 6.8-7.2, add the balance of 102.5g deionized water, stir and mix evenly and cool down to obtain a neutral descaling and dispersing agent for oilfields.

[0027] Among them, the active ingredient of hydroxyethylene diphosphonic acid is 50.45% aqueous solution.

[0028] The synthesis process of acrylic acid-2-acrylamide-2-methylpropa...

Embodiment 2

[0030] The formula of neutral descaling and dispersing agent consists of two components:

[0031] Hydroxyethylene diphosphonic acid 18 parts

[0032] Hexamethylene diamine tetramethylene phosphonic acid 4 parts

[0033] Acrylic acid-2-acrylamide-2-methylpropanesulfonic acid copolymer 8 parts

[0034] Potassium hydroxide 14 parts

[0035] 56 parts of deionized water

[0036] The specific preparation process is: add 185g deionized water, 90g hydroxyethylene diphosphonic acid, 20g hexamethylenediamine tetramethylene phosphonic acid and 40g acrylic acid-2-acrylamide-2-methylpropanesulfonic acid copolymer in sequence Put it into the reaction kettle, stir evenly, slowly add potassium hydroxide and control the system temperature to ≤70°C, adjust the pH value of the system to 6.8-7.2, add the remaining 95g of deionized water, stir and mix evenly, and cool down to obtain oil field neutral descaling dispersion agent.

[0037] Among them, hydroxyethylene diphosphonic acid is an aque...

Embodiment 3

[0041] The formula of neutral descaling and dispersing agent consists of two components:

[0042] Amino trimethylene phosphonic acid 10 parts

[0043] 10 parts of hydroxyethylene diphosphonic acid

[0044] Acrylic acid-2-acrylamide-2-methylpropanesulfonic acid copolymer 5 parts

[0045] Potassium hydroxide 15 parts

[0046] 60 parts deionized water

[0047] The specific preparation process is: add 185g of deionized water, 25g of aminotrimethylene phosphonic acid, 100g of hydroxyethylidene diphosphonic acid and 25g of acrylic acid-2-acrylamide-2-methylpropanesulfonic acid copolymer into the reactor in sequence In the medium, stir evenly, slowly add potassium hydroxide and control the system temperature to ≤70°C, adjust the pH value of the system to 6.8-7.2, add the remaining 90g of deionized water, stir and mix evenly and cool down to obtain a neutral descaling and dispersing agent for oilfields.

[0048] Among them, amino trimethylene phosphonic acid is an aqueous solution w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com