Method for extracting senplus from diutan gum fermenting liquid

A technology of diyou gum and fermentation liquid, which is applied in the field of extraction of fermentation products to achieve the effects of mild conditions, improved quality performance and economic value, and fast enzymolysis reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

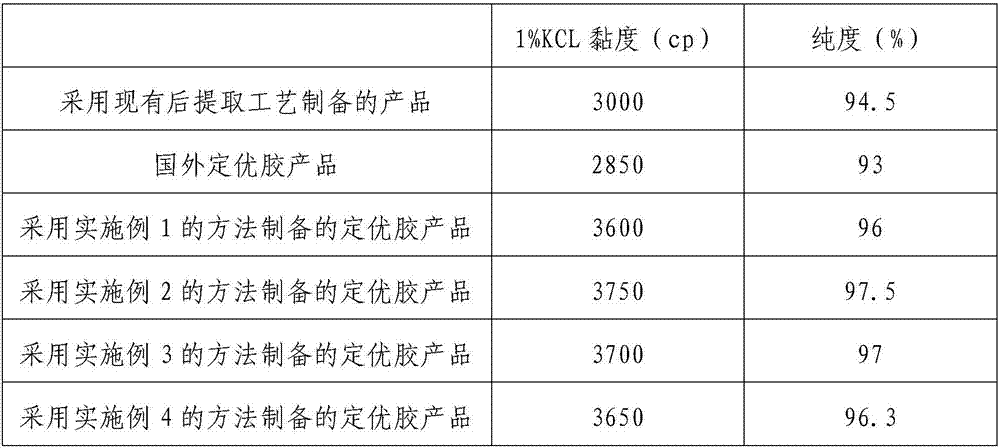

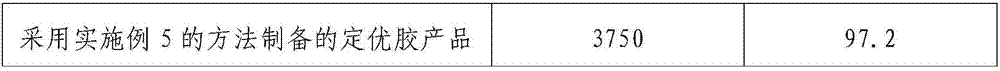

Examples

Embodiment 1

[0054] A method for extracting diyout gum from diyout gum fermentation broth, which is to extract diyout gum from the fermented broth after centrifugation and extraction; comprising the following process steps:

[0055] A. Fermentation broth pretreatment

[0056] A1. Add lysozyme with an enzyme activity of 100,000 u / g to the fermented broth containing diyout gum at pH=6-8, the concentration of lysozyme in the fermented broth is 100ppm, stir well and maintain the reaction for 5 hours;

[0057] A2, the fermented liquid after the reaction in step A1 is warmed up to 130 DEG C and maintained for 8 minutes and then lowered to 60 DEG C, adding acid protease with an enzyme activity of 50000u / g, the concentration of acid protease in the fermented liquid is 200ppm, at pH=3- 4. Under the condition of temperature of 50°C, react for 4 hours to make the pretreated fermentation broth;

[0058] B. Primary extraction: According to the ratio of fermented liquid after pretreatment: ethanol solu...

Embodiment 2

[0068] The difference between this embodiment and embodiment 1 is:

[0069] A method for extracting diyout gum from diyout gum fermentation broth, which is to extract diyout gum from the fermented broth after centrifugation and extraction; comprising the following process steps:

[0070] A. Fermentation broth pretreatment

[0071] A1. Add lysozyme with an enzyme activity of 100,000 u / g to the fermented broth containing diyout gum at pH=6-8, the concentration of lysozyme in the fermented broth is 200ppm, stir well and maintain the reaction for 3 hours;

[0072] A2. Raise the temperature of the fermented broth after the reaction in step A1 to 140°C for 5 minutes and then drop to 70°C, add acid protease with enzyme activity of 50000u / g, the concentration of acidic protease in the fermented broth is 400ppm, at pH=3- 4. Under the condition of 60°C, react for 2 hours to make pretreated fermentation liquid;

[0073] B. Primary extraction: According to the ratio of fermented liquid ...

Embodiment 3

[0080] The difference between this embodiment and embodiment 1 is:

[0081] A method for extracting diyout gum from diyout gum fermentation broth, which is to extract diyout gum from the fermented broth after centrifugation and extraction; comprising the following process steps:

[0082] A. Fermentation broth pretreatment

[0083] A1. Add lysozyme with an enzyme activity of 100,000 u / g to the fermented broth containing diyout gum at pH=6-8, the concentration of lysozyme in the fermented broth is 150ppm, stir well and maintain the reaction for 4 hours;

[0084] A2. Raise the temperature of the fermented broth after the reaction in step A1 to 135°C for 7 minutes and then drop to 65°C, add acid protease with enzyme activity of 50000u / g, the concentration of acidic protease in the fermented broth is 300ppm, at pH=3- 4. Under the condition of temperature of 55°C, react for 3 hours to make pretreated fermentation liquid;

[0085] B. Primary extraction: According to the ratio of fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com