Lubricating oil

A lubricating oil and oil-soluble technology, applied in the field of lubricating oil, can solve the problems of difficult coexistence of modified components, difficult maintenance of lubricating oil performance, uneven dispersion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Dissolve sodium borate in distilled water to prepare solution A, dissolve lanthanum nitrate in absolute ethanol to prepare solution B, dissolve octadecyl pyridinium dithiophosphate (PyDDP) in alcohol aqueous solution, and heat to 80°C Stir until octadecyl dithiophosphate pyridinium salt is completely dissolved to obtain solution C, add solution A to solution C and mix well and keep warm at 80°C for 10 minutes, then add solution B dropwise, continue to react for 3 hours after the dropwise addition, and the reaction ends After standing still for 30 minutes, the temperature of the reaction solution was maintained at 80°C during the whole process, filtered while it was hot and washed with an alcohol solution of 80°C, and the washed product was dried in a vacuum drying oven to obtain modified nano-lanthanum borate. The alcohol aqueous solution is 80% ethanol solution, the mass ratio of lanthanum nitrate and octadecyl pyridinium dithiophosphate is 1:1, and the molar ratio of l...

Embodiment 2

[0029] Weigh sodium nitrate, sodium silicate and sodium hydroxide respectively according to the mass ratio of 2:1:30, import the weighed sodium nitrate, sodium silicate and sodium hydroxide into a beaker, add water and stir to dissolve, and dissolve the solution completely Heat to 200°C and keep it warm for 20 hours, then cool naturally to room temperature, centrifuge and filter to recover the reaction product, and alternately wash with deionized water and ethanol for 2 to 3 times (2 to 3 times refer to the total number of water washing and alcohol washing) to obtain product A , ultrasonically disperse product A into ethanol solution, then add silane coupling agent KH-560, heat to 60°C and stir for 90 minutes, the weight of silane coupling agent KH-560 added is half of the weight of product A, then naturally cool to At room temperature, centrifuge and filter to recover the reaction product, and wash with ethanol for 2 to 3 times to obtain modified nano-magnesium silicate.

Embodiment 3

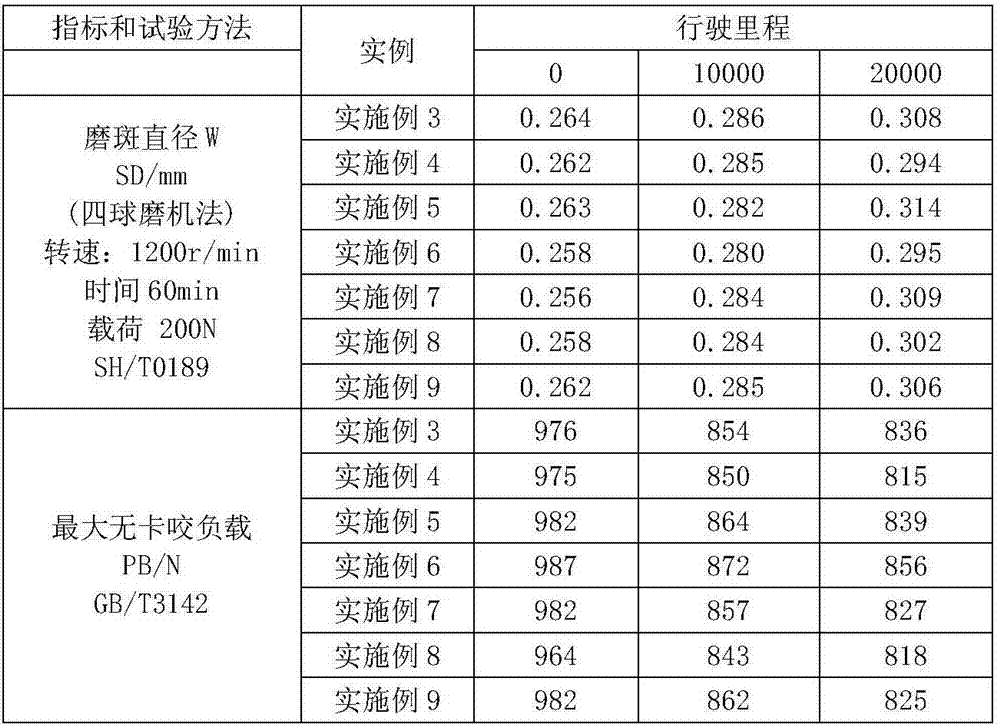

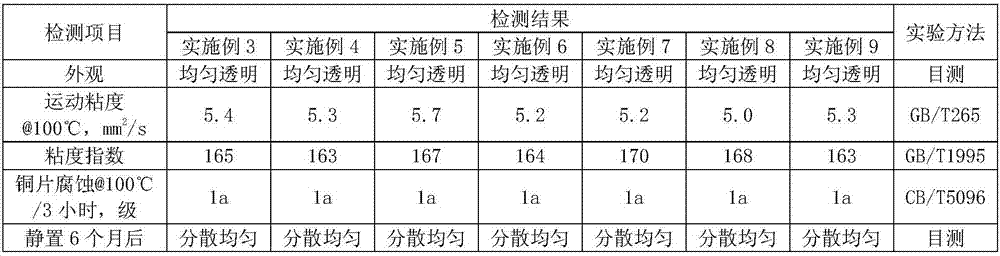

[0031] The total weight of lubricating oil is 100 parts by weight, including 4 parts by weight of dispersants, 3 parts by weight of viscosity modifiers, 0.75 parts by weight of antiwear agents, 0.3 parts by weight of wear reducers, 0.05 parts by weight of detergents, and the balance as base oil.

[0032] The anti-wear agent is prepared from zinc dialkyldithiophosphate, modified nano-magnesium silicate, and modified nano-lanthanum borate according to the weight ratio of 4:10:1; the mass of oil-soluble organic molybdenum and modified nano-lanthanum borate The ratio is 6:1; the dispersant is polyisobutenyl succinimide; the viscosity modifier is polymethacrylate PMA; the detergent is TBN400; the oil-soluble organic molybdenum is molybdenum dialkyldithiophosphate; The oil is polyalphaolefin synthetic base oil.

[0033] Above-mentioned lubricating oil adopts following method to obtain:

[0034] Accurately weigh each component according to the ratio of lubricating oil, first add th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com