Low-temperature high-viscosity quick-frozen liquid composition and preparation and freezing methods thereof

A liquid composition and high-viscosity technology, which is applied in the direction of freezing/cooling preservation of meat/fish, etc., can solve the problems of difficulty in maintaining the temperature of the freezing liquid at low temperature, the decrease of the cleanliness of the freezing liquid, and the difficulty of implementation, etc., to achieve fast freezing effect, The effect of increasing the viscosity index and improving the turnover efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The present embodiment adopts the following steps to prepare quick-freezing liquid:

[0033] Step 1: Mix 60% maltose, 30% dextrin, 3% maltotriose, and 7% glucose in proportion, and heat to 60-80°C, so that all components are fully mixed and formed into a syrupy texture with a viscous texture , and the mixed syrup-like liquid with no coke inside;

[0034] Step 2: Mix 15% sodium chloride, 6% sodium propionate, 15% glycerin, 10% glucose syrup, 13% mixed syrup, 10% nano-scale water-soluble mineral salts (calcium gluconate, zinc gluconate Mix in any ratio, preferably the ratio of the two is 3-4:1), and mix evenly with distilled water, raise the temperature to 40-45°C to increase the speed of mixing evenly, and make quick-freezing liquid.

[0035] Select small and medium-sized economical fish. The thickness of the fish body in its natural state does not exceed 8cm. Remove the viscera, wash the mucus on the surface, and put it into a polyethylene vacuum packaging bag as a fro...

Embodiment 2

[0047] Step 1: Mix 55% maltose, 35% dextrin, 5% maltotriose, and 5% glucose in proportion, and heat to 60-80°C, so that all components are fully mixed and formed into a syrup-like texture with a viscous texture , and the mixed syrup-like liquid with no coke inside;

[0048] Step 2: Mix 10% sodium chloride, 5% sodium propionate, 12% glycerol, 13% glucose syrup, 15% mixed syrup, 8% nano-scale water-soluble mineral salts (calcium gluconate, zinc gluconate It can be mixed in any ratio, preferably the ratio of the two is 1:1-2), after uniform mixing with distilled water, the temperature is raised to 35-40°C to increase the speed of uniform mixing, and the quick-freezing liquid is obtained.

[0049] Chaoshan beef balls with a diameter of 3-4cm are used as frozen objects, and they are arranged in a single layer without stacking. They are placed in polyethylene vacuum packaging bags as frozen objects, and the vacuum is drawn out as much as possible and the bag is closed.

[0050] The...

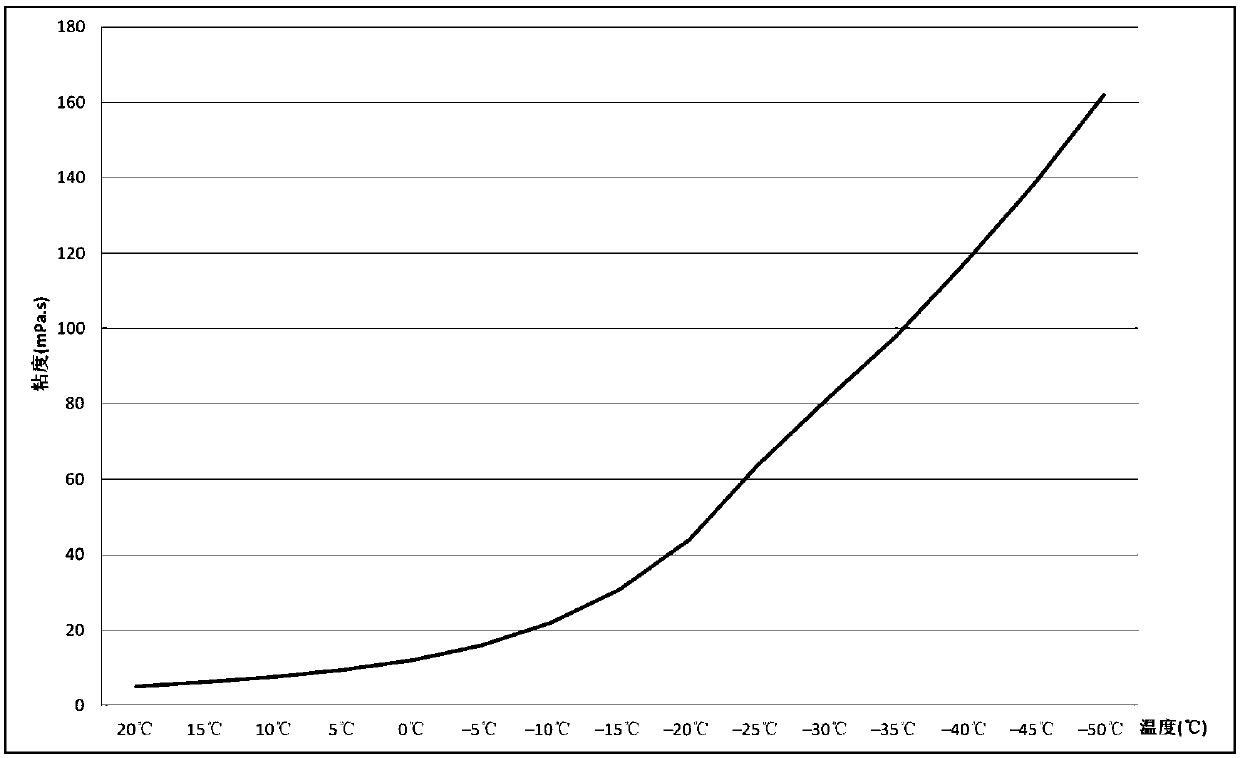

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com