Full-synthetic continuously variable transmission (CVT) transmission fluid as well as preparation method and application thereof

A continuously variable transmission and transmission fluid technology, applied in the field of automobile transmission fluid, can solve the problems of less CVTF, large differentiation, and late CVT research, and achieve the effects of high transmission efficiency, excellent comprehensive performance, and excellent viscosity index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

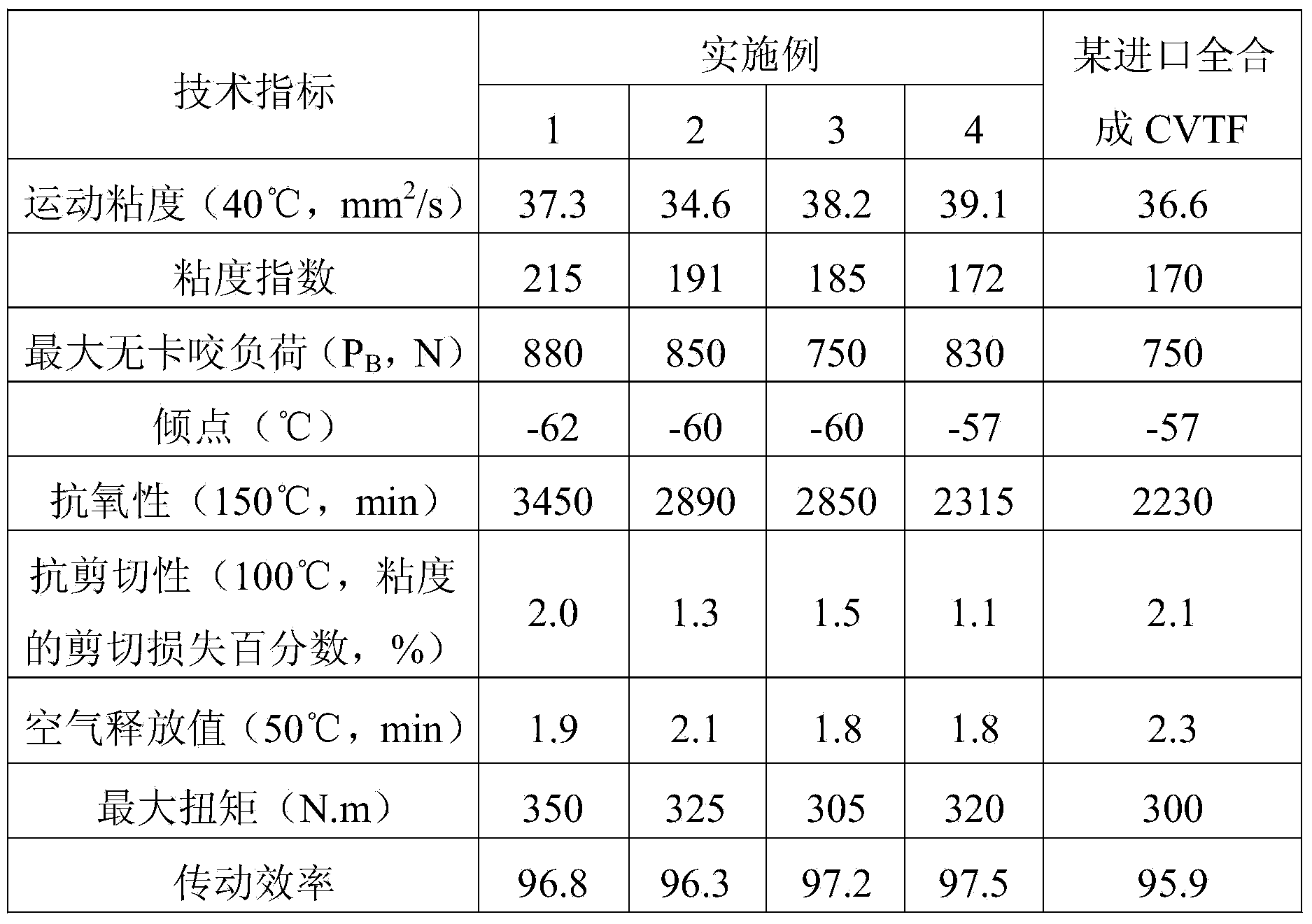

Examples

Embodiment 1

[0038] Example 1: Preparation of fully synthetic continuously variable transmission transmission fluid

[0039] Heat 100Kg IV base oil to 45°C, add 5Kg polymethacrylate at a stirring speed of 500rpm, stir at 500rpm for 20min and dissolve completely; then add 0.6Kg trinonyl phosphite, 1.8Kg dialkyl disulfide Phosphate amine salt, 0.6Kg thiophosphated polyisobutylene barium salt, 2.4Kg high base number sulfurized alkyl phenol calcium, 6Kg polyisobutylene succinimide, 0.2Kg phenyl-α-naphthylamine, 0.4Kg2,2 ,4-trimethyl-1,2-dihydroquinoline polymer, 0.2Kg sterically hindered phenol derivative, 1Kg benzene triazole fatty acid ammonium salt and 2Kg imidazoline borate oleate were stirred at 500rpm for 60min to obtain the total synthesis CVT transmission fluid.

Embodiment 2

[0040] Example 2: Preparation of fully synthetic continuously variable transmission transmission fluid

[0041] Mix 100Kg IV base oil and 5Kg V base oil, heat to 60°C, add 3Kg polymethacrylate at a stirring speed of 800rpm, stir at 600rpm for 60min to dissolve completely; then add 0.25Kg trinonyl phosphite , 0.25Kg dialkyldithiophosphate amine salt, 0.8Kg sulfur phosphide polyisobutylene barium salt, 1.2Kg high base number sulfurized alkyl phenol calcium, 3.5Kg polyisobutylene succinimide, 0.1Kg phenyl- α-naphthylamine, 0.3Kg 2,2,4-trimethyl-1,2-dihydroquinoline polymer, 0.2Kg sterically hindered phenol derivative, 0.8Kg benzene triazole fatty acid ammonium salt and 1.2Kg imidazole oleate The boronic acid ester was stirred at 600 rpm for 90 min to obtain a fully synthetic continuously variable transmission fluid.

Embodiment 3

[0042] Example 3: Preparation of fully synthetic continuously variable transmission transmission fluid

[0043]Mix 100Kg IV base oil and 10Kg V base oil, heat to 60°C, add 3Kg polymethacrylate at a stirring speed of 600rpm, stir at 800rpm for 50min to dissolve completely; then add 0.8Kg trinonyl phosphite , 1.2Kg dialkyldithiophosphate amine salt, 1Kg sulfur phosphide polyisobutylene barium salt, 1.5Kg high base number sulfurized alkyl phenol calcium, 2Kg polyisobutylene succinimide, 0.1Kg phenyl-α- Naphthylamine, 0.25Kg 2,2,4-trimethyl-1,2-dihydroquinoline polymer, 0.15Kg sterically hindered phenol derivative, 0.5Kg benzene triazole fatty acid ammonium salt and 0.5Kg imidazoline boron oleate The ester was stirred at 800 rpm for 70 minutes to obtain a fully synthetic continuously variable transmission fluid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com