Lubricating oil base oil production method

A technology for lubricating base oils and production methods, applied in lubricating compositions, the petroleum industry, and treating hydrocarbon oils, etc., can solve problems such as high reaction temperature at the outlet of the bed, limited operating cycle, etc., achieve optimization effects, reduce severity, The effect of saving operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

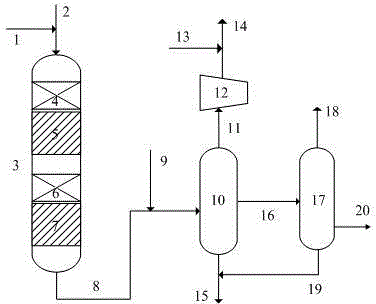

[0043] use figure 1 The process flow shown is to produce lubricating oil base oil by mixing and grading in series. In Example 1, two hydrogenation reaction zones connected in series are included. In the composite bed of the decondensation cracking catalyst in each reaction zone, the mixing volume ratio of the hydrocracking catalyst to the hydrocracking catalyst is 1:2, and the total amount of catalyst used is Both of Comparative Example 1 and Comparative Example 2 are the same. The hydrocracking catalyst used in Example 1 is FC-50 catalyst, and the hydrodecondensation catalyst is FDW-3 catalyst, both of which are commercial catalysts developed and produced by Fushun Petrochemical Research Institute.

[0044] The operating conditions and test results are listed in Table 3.

Embodiment 2

[0046] use figure 1 The process flow shown is to produce lubricating oil base oil by mixing and grading in series. In Example 1, two hydrogenation reaction zones connected in series are included. In the composite bed of the decondensation cracking catalyst in each reaction zone, the mixing volume ratio of the hydrocracking catalyst to the hydrocracking catalyst is 1:2, and the total amount of catalyst used is Both of Comparative Example 1 and Comparative Example 2 are the same. The hydrocracking catalyst used in Example 2 is FC-50G catalyst, and the hydrodecondensation catalyst is FDW-3 catalyst, both of which are commercial catalysts developed and produced by Fushun Petrochemical Research Institute.

[0047] The operating conditions and test results are listed in Table 3.

[0048] Table 2 Raw oil properties table.

[0049] project Raw oil source Decompression wax oil Density(20℃) / g·cm -3 0.8760 Distillation range / ℃ 339~541 Nitrogen / μg·g ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dew point | aaaaa | aaaaa |

| dry point | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com