Lubricating oil composition

A lubricating oil composition, a technology for lubricating oil, applied in the directions of lubricating composition, petroleum industry, additives, etc., can solve the problems of prolonged maintenance interval and oil change interval, high cost, difficult maintenance, etc., achieve good extreme pressure performance, prevent Melt loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

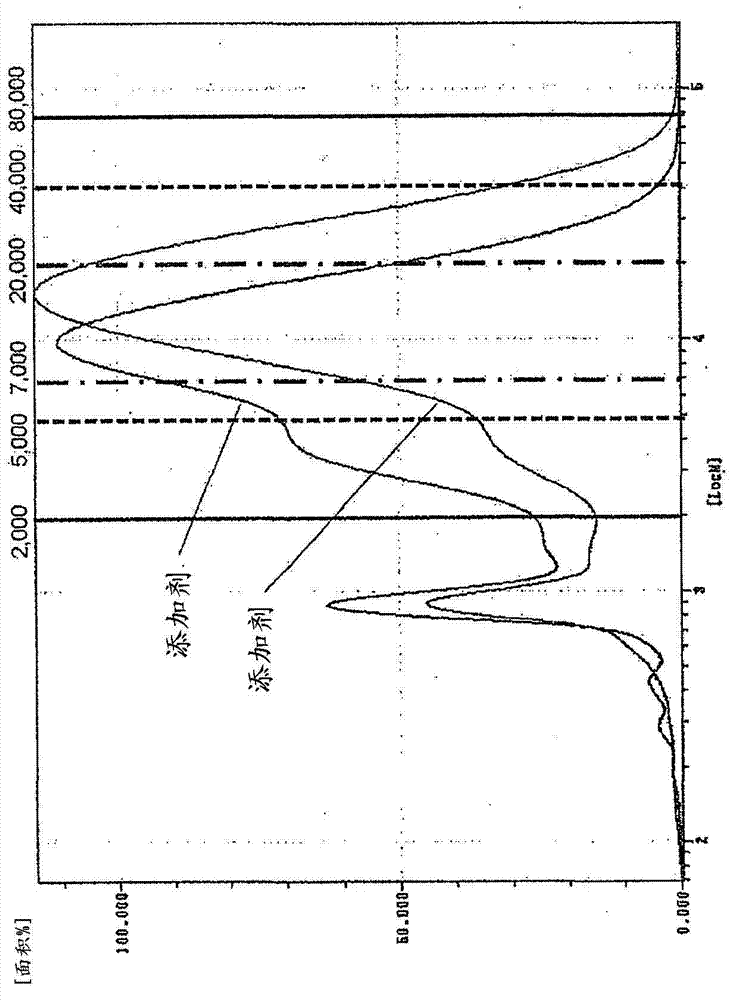

Image

Examples

Embodiment

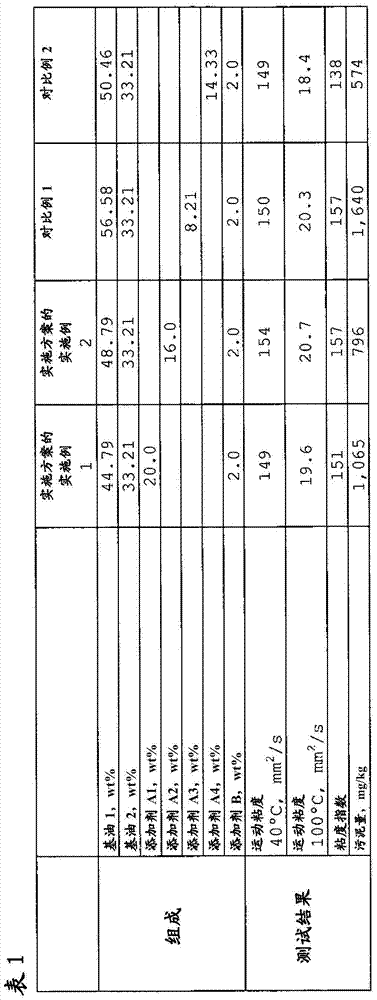

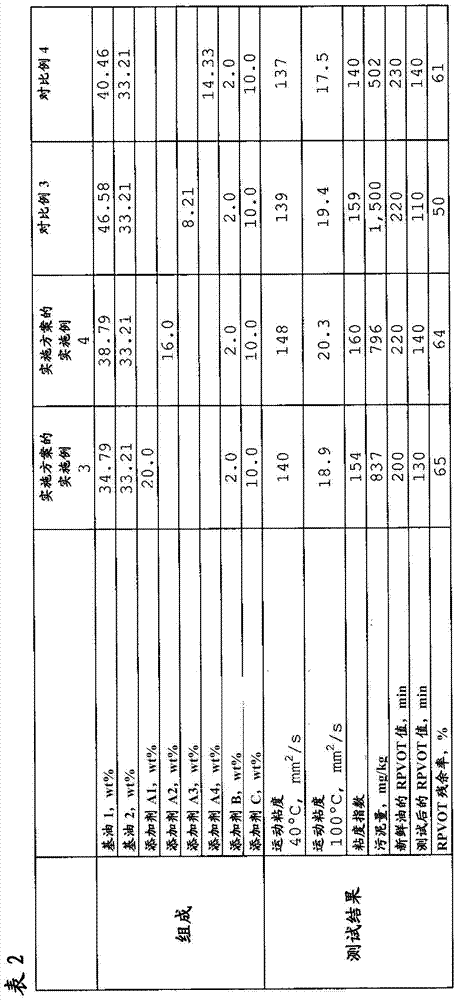

[0071] The lubricating oil composition of the present invention which has excellent extreme pressure performance (ability to prevent melting loss), generates a small amount of sludge and also has a high viscosity index will be more specifically described below by using examples and comparative examples of the embodiments, However, the present invention is not limited by these examples in any way.

[0072] The following constituent materials were used to prepare Examples and Comparative Examples of the embodiment.

[0073] 1. Base oil

[0074] Polyalphaolefin (PAO) synthetic oils are classified into Group IV according to the API (American Petroleum Institute) base oil classification.

[0075] (1-1) Base oil 1: polyalphaolefin (common name: PAO6, characterized by: kinematic viscosity at 40°C: 35.4mm 2 / s; kinematic viscosity at 100°C: 6.44mm 2 / s; viscosity index 136; density at 15°C: 0.8291g / cm 3 ; Aniline point: 130°C)

[0076] (1-2) Base oil 2: polyalphaolefin (common na...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| dispersity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com