Preparation method of nitrogen, sulfur and phosphorus heteroatom-doped carbon material

A carbon material and heteroatom technology, applied in the field of carbon material preparation, can solve the problem of small controllable range and achieve the effect of strong universality, easy operation, high efficiency and controllable doping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

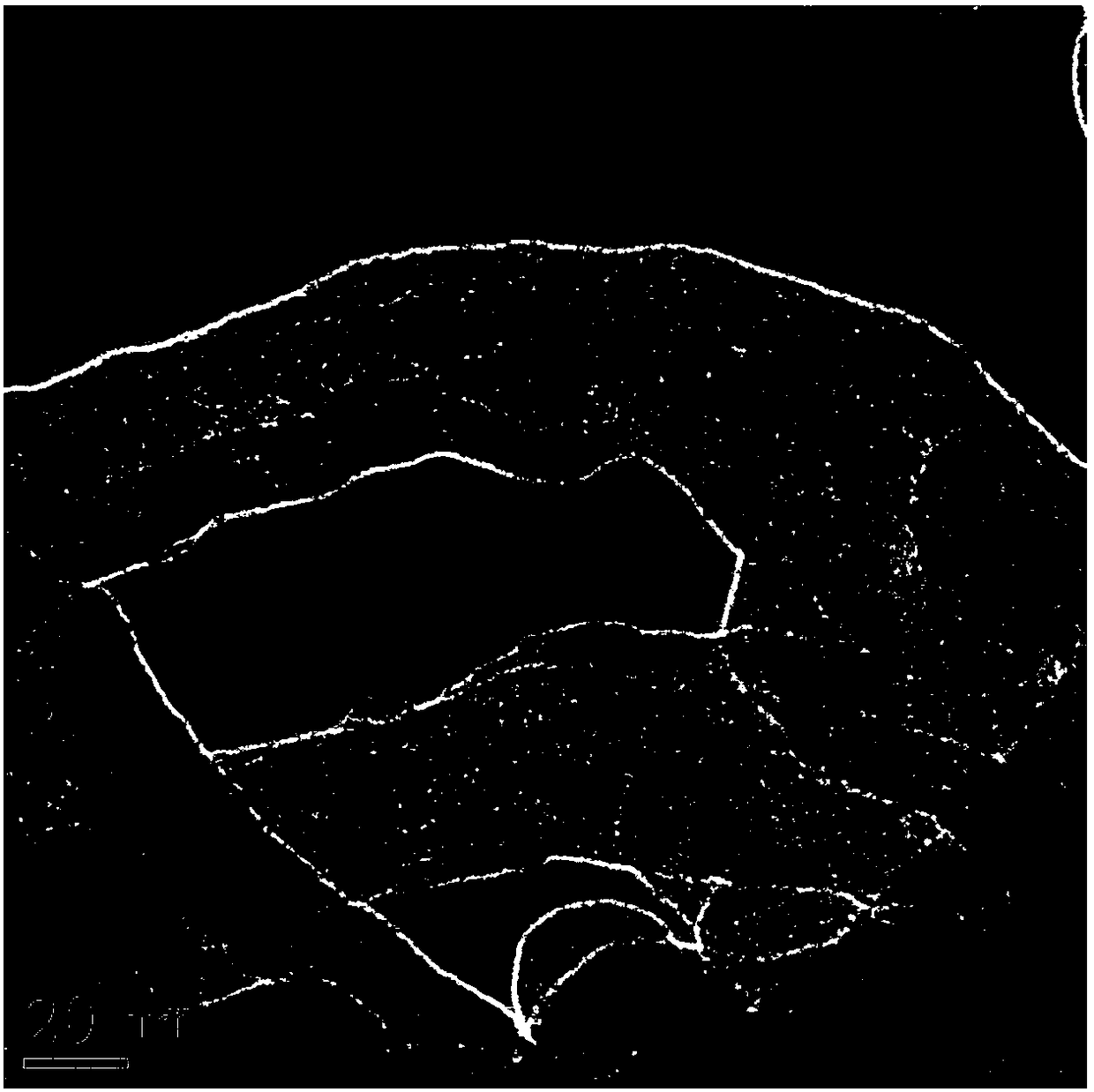

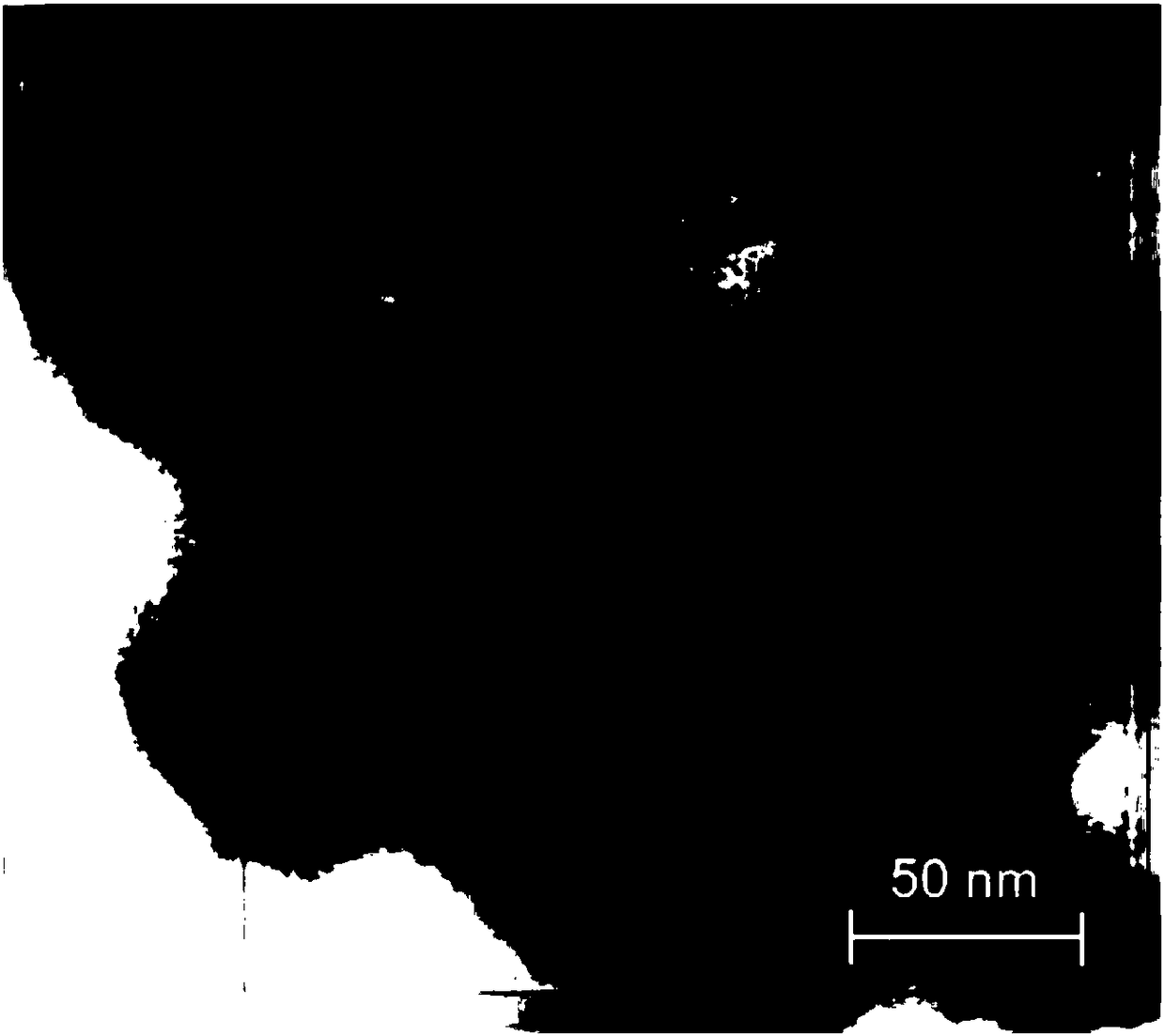

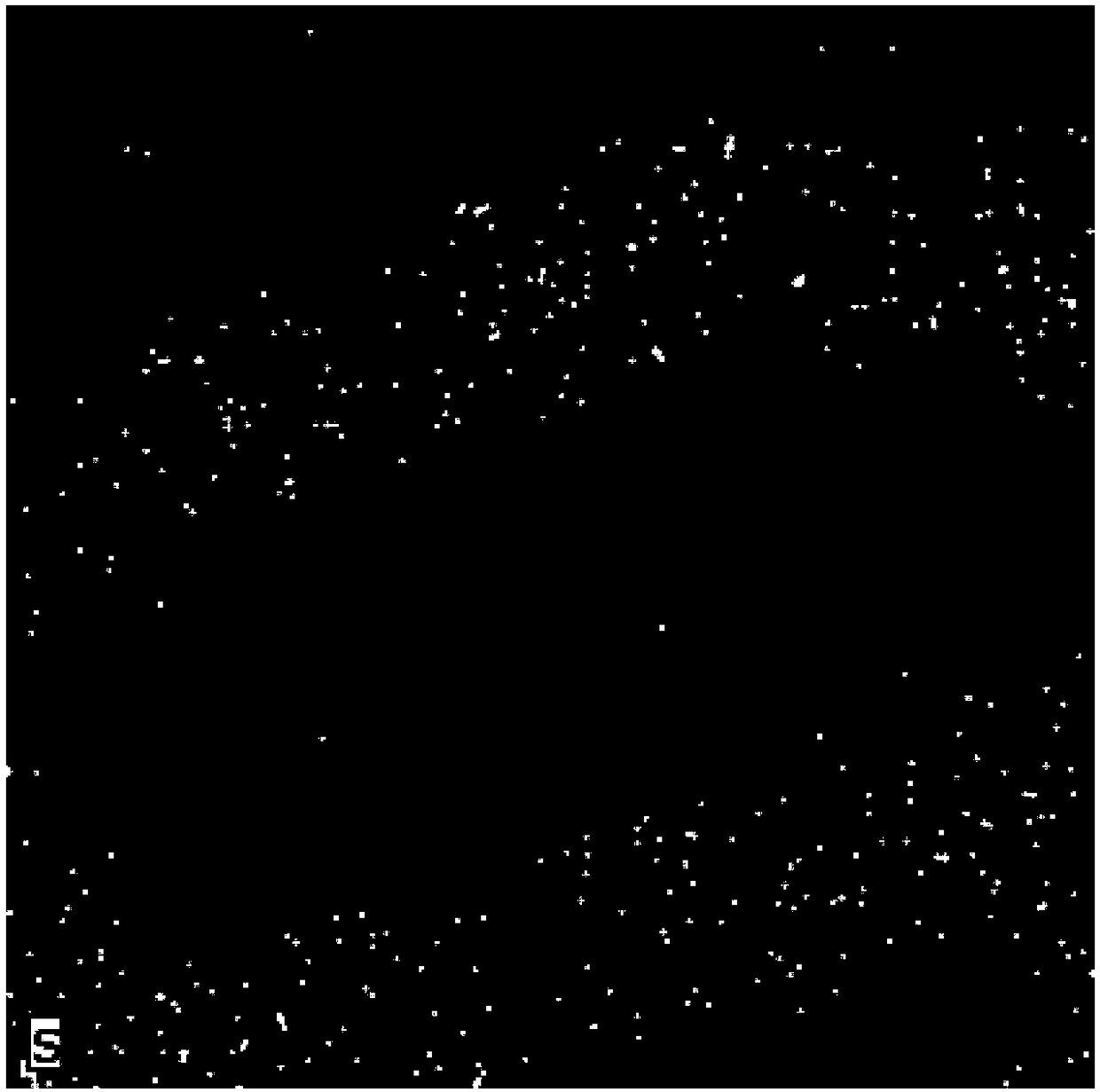

Image

Examples

Embodiment 1-6

[0031] Weigh 100 mg of carbon fluoride nanotubes and lay them flat on a porcelain boat, and place the porcelain boat in the center of the tube furnace until the temperature of the tube furnace rises to the target shown in Table 1 at a rate of 10°C / min under an argon atmosphere. Temperature: Inject thiophene into the high temperature area with a micro-injection pump at a rate of 1.5mL / h, and continue the injection for 2 hours. After the tube furnace is cooled to room temperature, take out the sample, wash it with ethanol and acetone three times, and measure it with an elemental analyzer. The sulfur content of doped carbon materials is shown in Table 1.

[0032] Table 1

[0033] Example

[0034] It can be seen from Table 1 that the sulfur doping content of fluorinated carbon nanotubes in the selected temperature range is above 4wt%, and the doping effect is the best at 800°C, and the sulfur content is 5.217wt%, which realizes the efficient doping of sulfur.

Embodiment 7-9

[0036] Weigh 100 mg of carbon fluoride nanotubes and lay them flat on a porcelain boat, and place the porcelain boat in the center of the tube furnace. The syringe pump injected thiophene into the high temperature area at the injection speed shown in Table 2, and continued to inject for 2 hours. After the tube furnace was cooled to room temperature, the samples were taken out and washed 4 times with ethanol and acetone respectively. The sulfur content is shown in Table 2.

[0037] Table 2

[0038] Example

[0039] It can be seen from Table 2 that when the injection speed of fluorinated carbon nanotubes is 1.5mL / h, a relatively ideal sulfur doping effect can be achieved.

Embodiment 10-11

[0041] Weigh 100 mg of carbon fluoride nanotubes and lay them flat on a porcelain boat, and place the porcelain boat in the center of the tube furnace. The syringe pump injects thiophene into the high-temperature area at a rate of 1.5mL / h, and continues the injection for the time shown in Table 3. After the tube furnace is cooled to room temperature, the sample is taken out, washed with ethanol and acetone for 5 times, and measured by an elemental analyzer. The sulfur content of the doped carbon materials is shown in Table 3.

[0042] table 3

[0043] Example

[0044] It can be seen from Table 3 that the ideal sulfur content can be achieved after thermal deposition of fluorinated carbon nanotubes for 2 hours, and the sulfur species on the surface decrease with the increase of the holding time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com