Titanium dioxide nanotube/molybdenum disulfide nanoflower compound as well as preparation method and application thereof

A technology of titanium dioxide and molybdenum disulfide, applied in the direction of nano-medicine, nano-technology, nano-technology, etc., can solve the problems of enzyme-like activity enhancement, etc., and achieve the effects of simple preparation process, easy-to-obtain preparation equipment, and broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

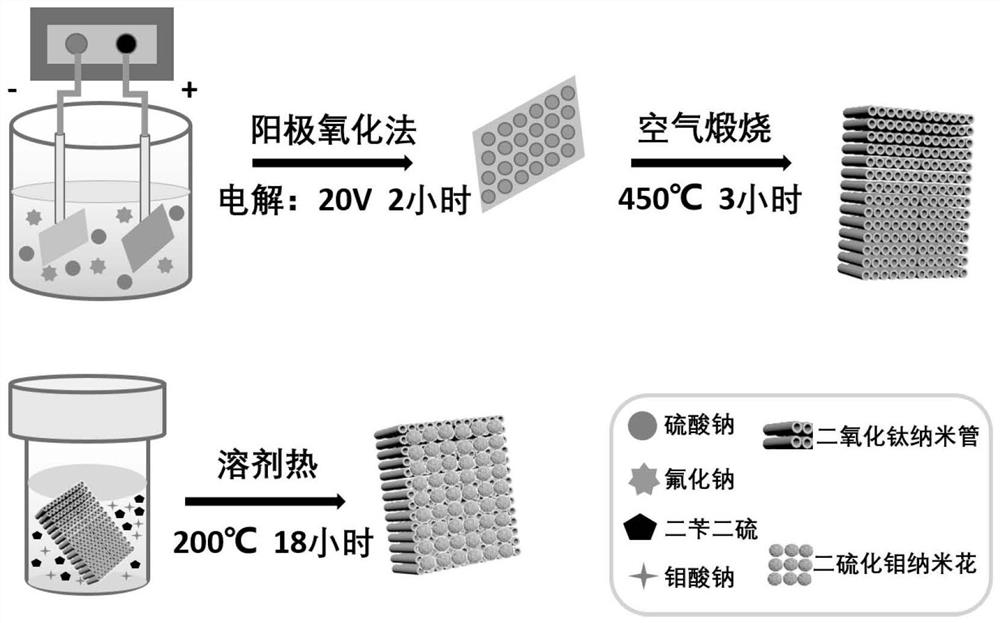

[0029] The specific steps of the preparation method of the titanium dioxide nanotube / molybdenum disulfide nanoflower composite involved in this embodiment include:

[0030](1) Dissolve 11.0-11.5g of sodium sulfate and 0.4-0.5g of sodium fluoride in 100mL deionized water as a buffer electrolyte, and use platinum and titanium as cathode and anode respectively, and apply 18-25V voltage, and reacted for 2 hours to obtain the reacted titanium sheet; then the titanium sheet after the step reaction was cleaned and dried, and then the dried titanium sheet was placed in a tube furnace for air calcination, so as not to exceed the temperature rise per minute The calcination temperature was raised to 450° C. at a rate of 5° C. and maintained for 3 hours. After the reaction was completed, it was naturally cooled to room temperature to obtain silver titanium dioxide nanotubes.

[0031] (2) Add 0.36g dibenzyl disulfide and 0.4g sodium molybdate in the mixed solvent of 60mL ethanol and water,...

Embodiment 2

[0034] The specific steps of the preparation method of the titanium dioxide nanotube / molybdenum disulfide nanoflower composite involved in this embodiment include:

[0035] (1) Utilize anodic oxidation method to prepare titanium dioxide nanotube: step is the same as embodiment 1

[0036] (2) Preparation of titanium dioxide nanotubes / molybdenum disulfide nanoflower composites by solvothermal method: add 0.3-g dibenzyl disulfide and 0.35-g sodium molybdate to a mixed solvent of 60mL ethanol and water, the volume of ethanol and water The ratio is 1:1, stirred and dissolved to obtain a mixed solution, and then the titanium dioxide nanotubes in step (1) are placed in the mixed solution and transferred together into a polytetrafluoroethylene sealed tank to seal and put into a high-temperature reactor for solvent Thermal reaction, the reaction temperature is 180-℃, and the reaction time is 16-hours. After the reaction is completed, after cooling to room temperature naturally, the pol...

Embodiment 3

[0038] The specific steps of the preparation method of the titanium dioxide nanotube / molybdenum disulfide nanoflower composite involved in this embodiment include:

[0039] (1) Utilize the anodic oxidation method to prepare titanium dioxide nanotubes;

[0040] (2) Preparation of titanium dioxide nanotube / molybdenum disulfide nanoflower composite by solvothermal method: add -0.4g dibenzyl disulfide and -0.45g sodium molybdate in 60mL ethanol and water mixed solvent, the volume of ethanol and water The ratio is 1:1, stirred and dissolved to obtain a mixed solution, and then the titanium dioxide nanotubes in step (1) are placed in the mixed solution and transferred together into a polytetrafluoroethylene sealed tank to seal and put into a high-temperature reactor for solvent Thermal reaction, the reaction temperature is -220°C, and the reaction time is -20 hours. After the reaction is completed, cool down to room temperature naturally, take out the polytetrafluoroethylene tank, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com