Method for Predicting the Likelihood of Occurrence of Anomalies in Oil-Immersed Electrical Equipment

A prediction method and technology of electrical equipment, applied to electrical components, parts of transformers/inductors, circuits, etc., can solve problems such as inability to diagnose unfavorable conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0035] The procedure of the present invention is shown below based on specific research results.

[0036]First, based on ASTM D 1275B, which is a test method of ASTM (American Society for Testing and Materials: American Society for Testing and Materials), transformer oil after confirming that it does not contain corrosive sulfur is prepared. Next, a predetermined amount of DBDS is added to this transformer oil. In this experiment, 30 and 300 ppm of DBDS were added. 4 g of this transformer oil and a copper plate were enclosed in a bottle having an inner volume of 10 cc, and a rubber stopper was plugged, followed by heating at a predetermined temperature and time.

[0037] DBDS, dibenzylsulfide, and bibenzyl contained in the heated transformer oil are analyzed by gas chromatography / mass analyzer (GC / MS), and the concentrations of these compounds can be determined.

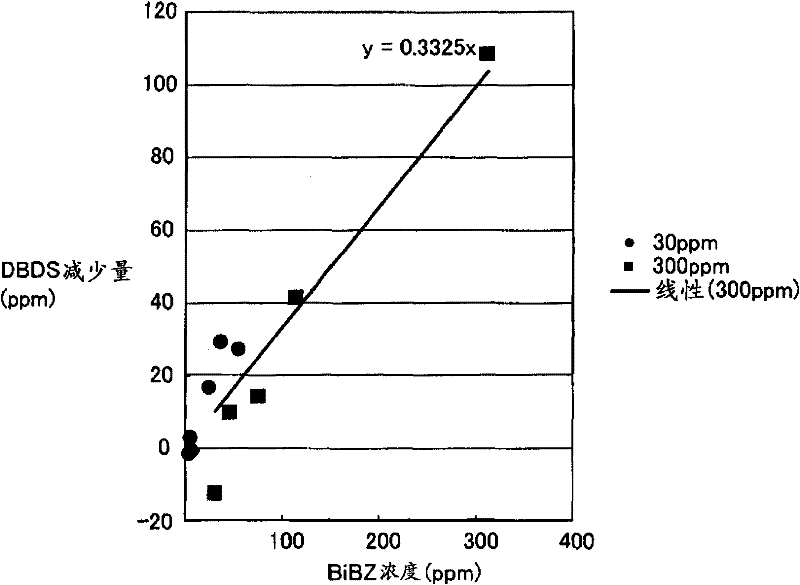

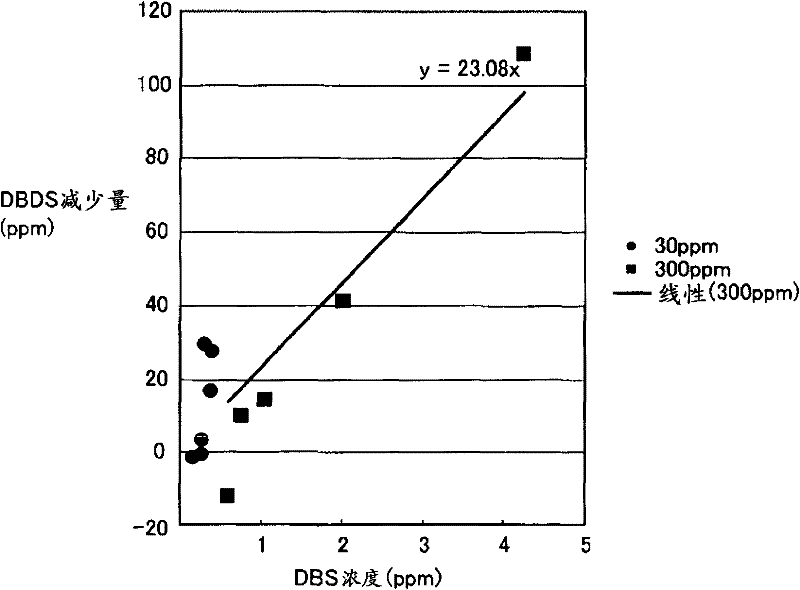

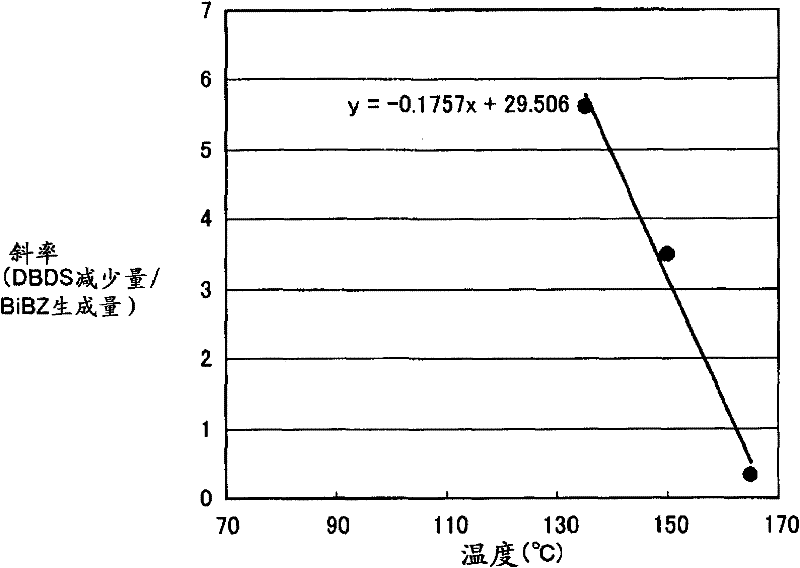

[0038] As an example, in the case of heating at 165°C, the relationship between the generated bibenzyl concentra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com