Preparation method and application of carbon nanofiber-based electrocatalyst

A technology of carbon nanofibers and catalysts, applied in the field of electrocatalysis, can solve problems such as hindering efficient conversion of energy, small number of active sites, unfavorable performance, etc., achieve excellent electrocatalytic performance and cycle stability, and the preparation method is simple and convenient. Effect of improving stability and conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

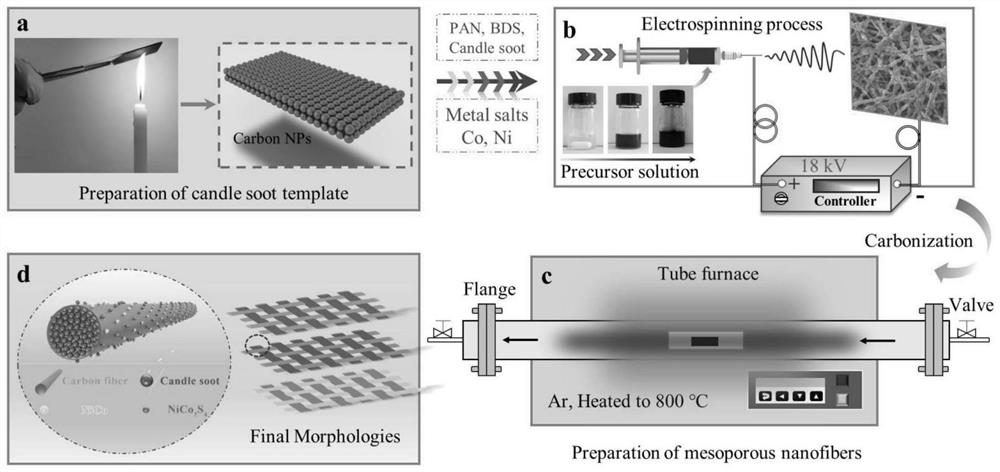

[0035] In some embodiments of the present invention, the preparation method of the carbon nanofiber-based electrocatalyst comprises the following steps:

[0036] Disperse candle ashes in an organic solvent, then add high molecular polymer, dibenzyl disulfide (BDS), after stirring, add cobalt salt and nickel salt, and continue stirring to obtain a precursor solution;

[0037] Electrospinning the precursor solution, collecting the fiber precursor, and drying;

[0038] The dry fiber precursor is air-fired at 150-300° C. for 1-3 hours, and then carbonized at high temperature in an inert atmosphere to obtain a carbon nanofiber-based electrocatalyst.

[0039] The preparation method of carbon nanofiber-based electrocatalyst of the present invention is as follows figure 1 Shown: put the glass piece in the candle flame, after burning for a period of time, scrape off the soot collected on the glass piece is the candle ashes, the candle ashes are carbon nanoparticles; put the candle ash...

Embodiment 1

[0049] The preparation method of carbon nanofiber-based electrocatalyst in this embodiment is:

[0050] Put the glass piece in the candle flame, and scrape off the soot collected on the glass piece as candle ash; dissolve 0.323g of candle ash particles in 5ml of N,N-dimethylformamide solution, and perform ultrasonic dispersion treatment for 3h, Then 0.323g of polyacrylonitrile (MW=150000) and 0.257g of dibenzyl disulfide were dissolved into the above solution and stirred for 12h, and finally 0.75mmol of cobalt nitrate hexahydrate and 0.75mmol of nickel nitrate hexahydrate were added to the solution and stirred for 12h .

[0051] Package the successfully prepared precursor solution above into a 10ml syringe, set the distance between the needle tip and the receiver to 13cm, set the voltage applied between the positive and negative electrodes during the spinning process to 18kV, and set the injection speed of the syringe to 0.2ml / h, the spinning temperature is 30°C, and the hum...

Embodiment 2

[0056] The difference between the preparation method of the carbon nanofiber-based electrocatalyst of Example 2 and Example 1 is that Example 2 is subjected to high-temperature carbonization at 700° C. for 2 hours, and the others are the same as Example 1.

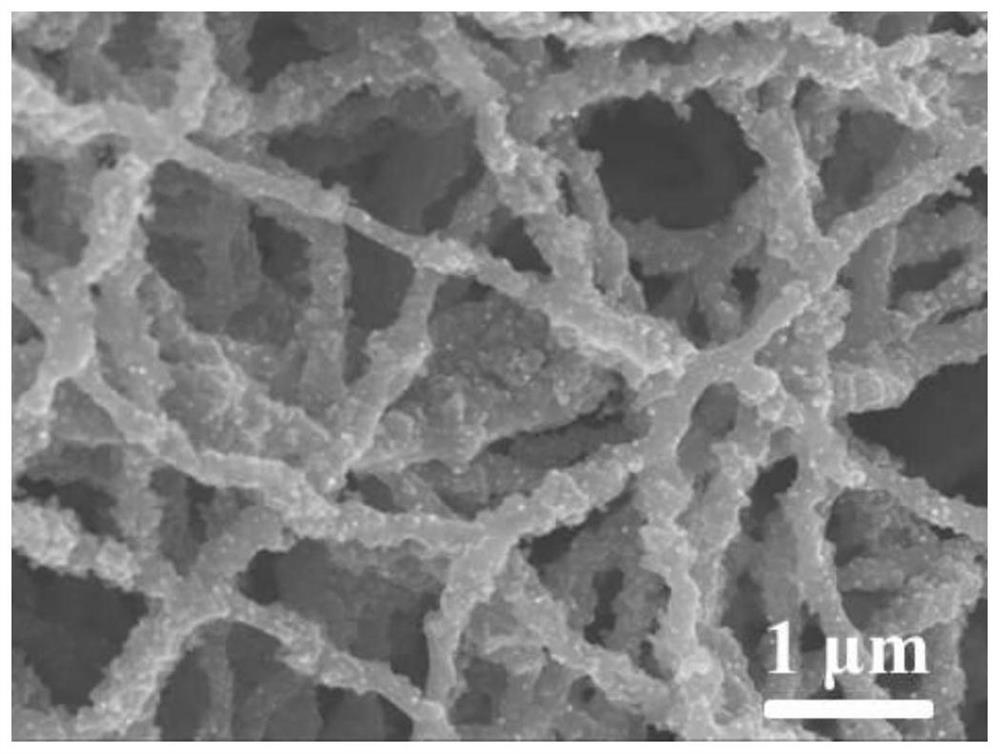

[0057] Use scanning electron microscope to characterize the morphology of the carbon nanofiber-based electrocatalyst that embodiment 2 makes, its SEM figure is as follows Figure 4 As shown, a small amount of nanoparticles were loaded on the fiber surface.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com