Preparation method and application of a carbon nanofiber-based electrocatalyst

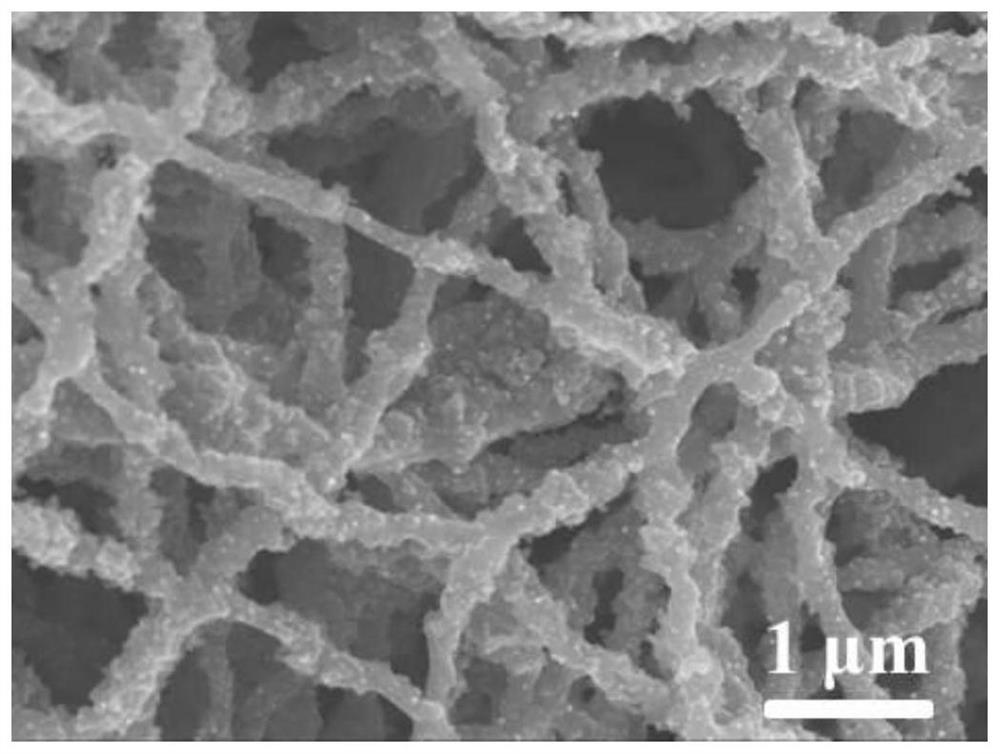

A carbon nanofiber, catalyst technology, applied in the field of electrocatalysis, can solve the problems of a small number of active sites, unfavorable performance, unfavorable charge and mass transfer, etc., achieve a simple and convenient preparation method, improve stability and conductivity, excellent fiber The effect of network structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

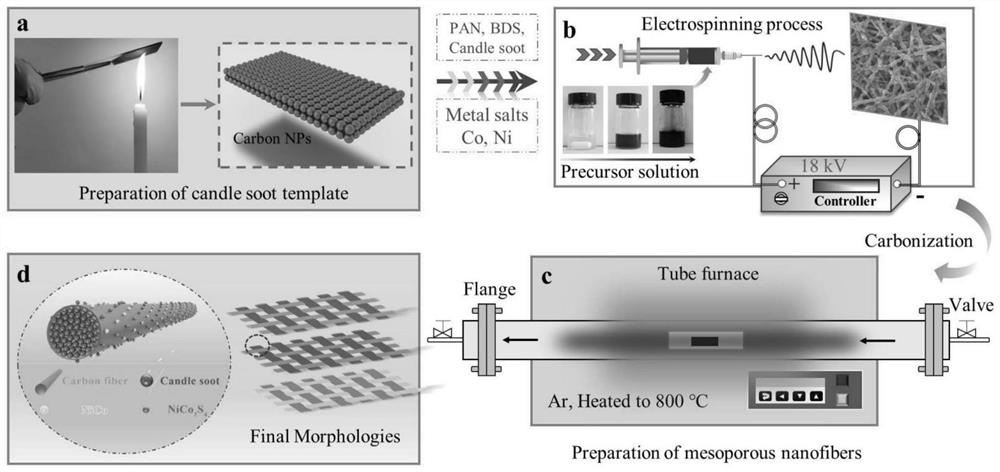

Method used

Image

Examples

preparation example Construction

[0038] The dried fiber precursor is calcined in the air at 150 to 300 ° C for 1 to 3 hours, and then carbonized at a high temperature in an inert atmosphere to obtain

[0042] The high molecular polymer used in the present invention is preferably polyacrylonitrile (PAN) and / or polyvinylpyrrolidone. polypropylene

[0044] The mass ratio of candle ash and high molecular polymer is preferably 1:(0.8-1.5). Dibenzyl disulfide, cobalt and nickel salts

[0046] The high-temperature carbonization of the present invention is preferably: high-temperature carbonization at 700-800° C. for 1-3 hours. More preferably 800°C

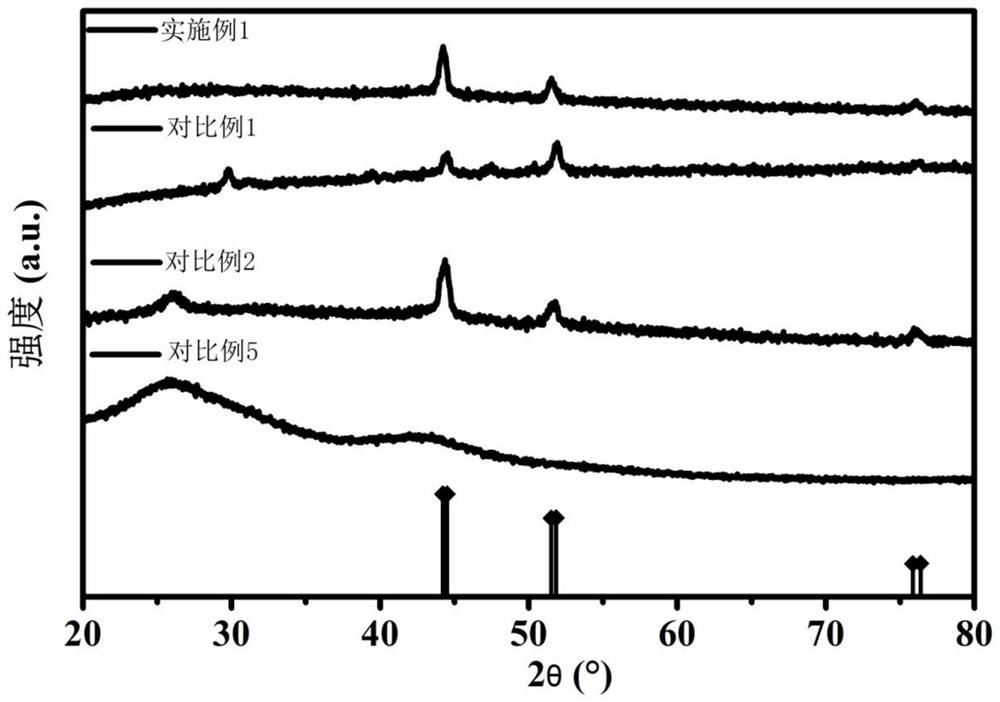

Embodiment 1

[0052] The dried fiber precursor was firstly fired in a muffle furnace at 200°C for 2h, and then transferred to a tubular

Embodiment 2

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com