A process for preparing foam foam by recycling foam waste

A foam and waste technology, applied in the field of foam, can solve the problems of waste of resources and the impact of production costs, and achieve the effects of improving stickiness, cohesion, and dispersion compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

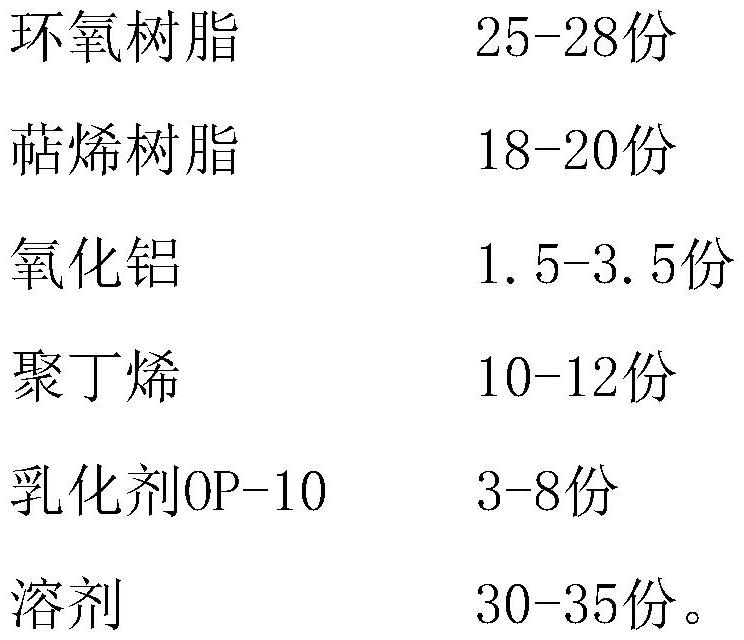

Method used

Image

Examples

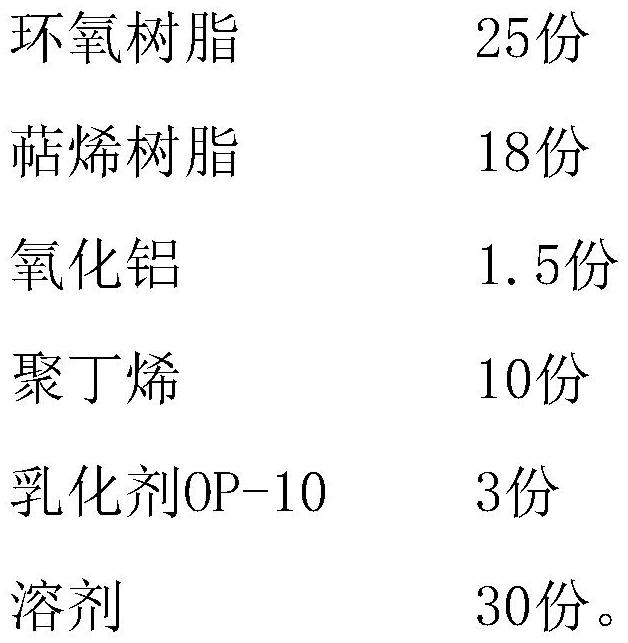

Embodiment 1

[0041] A process of foam waste reuse, including the process, including the following steps:

[0042] Step A: Cut the foam waste into three different particle waste;

[0043] Step B: The particulate waste obtained by cutting step A is dispersed uniform, then the foaming agent, antibacterial agent, toner, filler, mixed stir, resulting in a mixture;

[0044] Step C: Switch into the mixture obtained by the glue to step B, stir well, then add to the molding apparatus for molding, steam foaming treatment, and produce a foam;

[0045] Step D: Cut the foam material made by step c and make the bubble.

[0046] In step B, particulate waste, blowing agent, antibacterial agent, color agent, filler mix weight ratio of 70: 10: 3: 8: 18; in step c, mixture and glue mix weight ratio of 8 :1.

[0047] The particulate waste is a mixture of small particulate waste, in weight of particulate waste, and large particle waste, with a weight ratio of 5: 6: 2, and the small particle waste has an average pa...

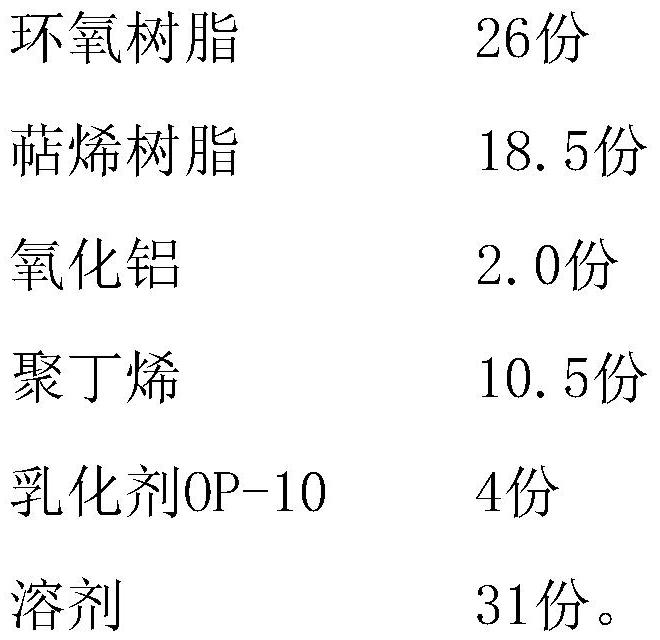

Embodiment 2

[0060] A process of foam waste reuse, including the process, including the following steps:

[0061] Step A: Cut the foam waste into three different particle waste;

[0062] Step B: The particulate waste obtained by cutting step A is dispersed uniform, then the foaming agent, antibacterial agent, toner, filler, mixed stir, resulting in a mixture;

[0063] Step C: Switch into the mixture obtained by the glue to step B, stir well, then add to the molding apparatus for molding, steam foaming treatment, and produce a foam;

[0064] Step D: Cut the foam material made by step c and make the bubble.

[0065] In the step B, the particulate waste, a blowing agent, an antibacterial agent, a color agent, and a mixed weight ratio of 72: 10.5: 4: 7: 18.5; the mixture and glue mixing weight ratio are 9 :1.

[0066] The particulate waste is a mixture of small particulate waste, the particulate waste and the large particulate waste, and the average particle diameter of 1.5 mm is 1.5 mm in weight ...

Embodiment 3

[0079] A process of foam waste reuse, including the process, including the following steps:

[0080] Step A: Cut the foam waste into three different particle waste;

[0081] Step B: The particulate waste obtained by cutting step A is dispersed uniform, then the foaming agent, antibacterial agent, toner, filler, mixed stir, resulting in a mixture;

[0082] Step C: Switch into the mixture obtained by the glue to step B, stir well, then add to the molding apparatus for molding, steam foaming treatment, and produce a foam;

[0083] Step D: Cut the foam material made by step c and make the bubble.

[0084] In the step B, the particulate waste, a blowing agent, an antibacterial agent, a color agent, a mixed weight ratio of 75: 11: 3-6: 6.5: 19; the mixture is mixed with the mixture and glue. Take 10: 1.

[0085] The particulate waste is a mixture of small particulate waste, and the particulate waste and large particulate waste are between 6.5: 4.5: 2, the small particle waste has an ave...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com