Lubricating grease used for three-pin type constant-velocity universal joint of vehicle

A lubricating grease and three-pin technology, applied in lubricating compositions, petroleum industry, etc., can solve the problems of high friction coefficient, no investigation of product anti-water and anti-rust performance, low wear performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

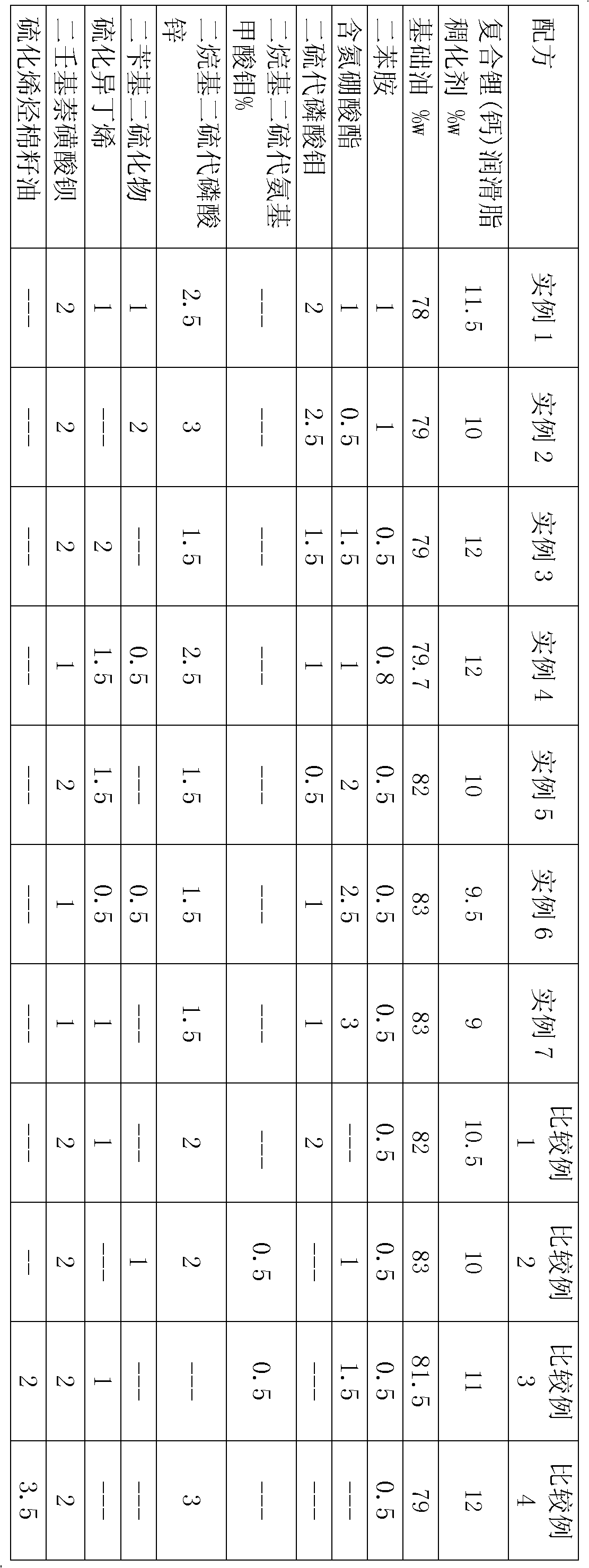

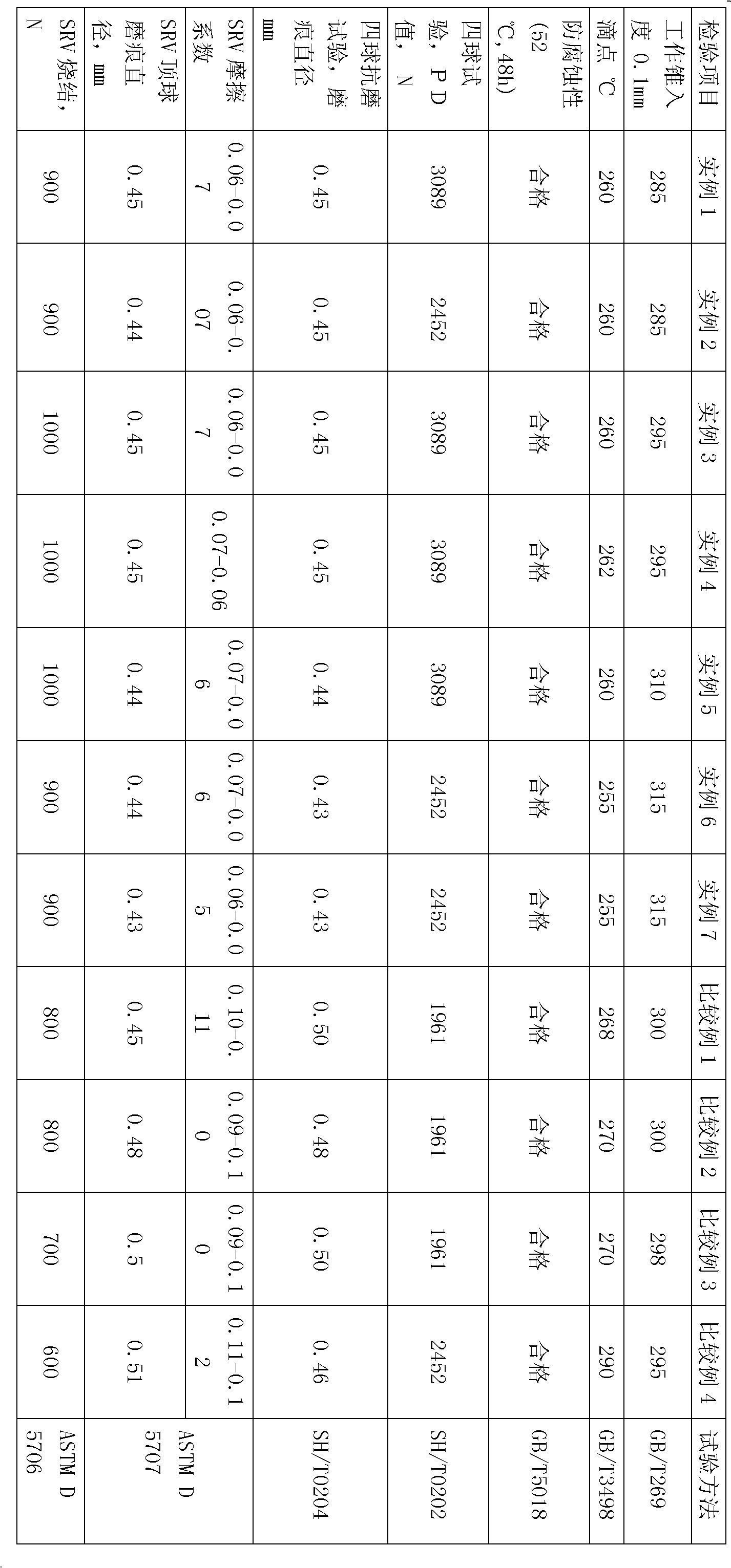

Examples

example 1

[0023] Put 950g of base oil and 200g of 12 hydroxystearic acid into a 4L reactor equipped with oil bath heating and two-way stirring, heat to 85-90°C under stirring, add 11g of lithium hydroxide and 7g of calcium hydroxide (with 90g of water dissolved and heated to 70-80°C), heated to 85-95°C, reacted and drained at this temperature for 60 minutes, then added 50g of sebacic acid, stirred for 20 minutes, added 36g of lithium hydroxide aqueous solution (dissolved with 180g of double water and Heat to 70-80°C) to react for 1.5 hours, then raise the temperature to 130-140°C for 30 minutes, continue to heat up, when the temperature reaches 150-160°C, add 26.5g of diphenylamine, stir and add 250g of base oil, continue heating Stop heating after reaching 210-220°C, add 860g of cooling oil, stir evenly, and add 26.5g of sulfurized isobutylene, 26.5g of dibenzyl disulfide, 66g of dialkyl zinc dithiophosphate, disulfide 53 g of molybdenum phosphate, 26.5 g of nitrogen-containing borate,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com