Sulfonic acid dual-core ion liquid catalyst and method using same for synthesizing polydiethylene glycol sebacate

An ionic liquid and catalyst technology, applied in chemical instruments and methods, preparation of organic compounds, catalysts for physical/chemical processes, etc., can solve the problems of low molecular weight and color difference of polybutylene succinate, and avoid Adverse effects, improved viscosity average molecular weight, good catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

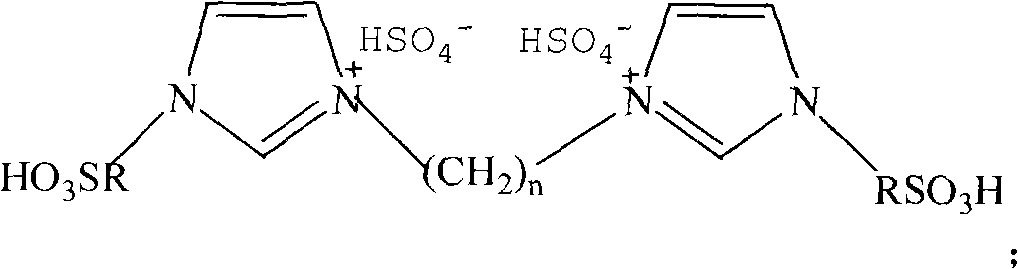

[0031] (A) Add 2.72g imidazole and 2.72g sodium ethylate to a three-necked flask, then add 50ml acetonitrile, stir and reflux at 70°C for 8 hours, add 4.32g 1,4-dibromobutane, stir and reflux at 70°C for 20 hours, Filter under reduced pressure, take the liquid, pour the liquid into a three-necked flask, add 4.88g of 1,3-propane sultone, stir and reflux at 100°C for 10 hours, then add 4g of 98% concentrated sulfuric acid, stir and reflux at 100°C 5 hours. The liquid was poured into a rotary evaporator, and rotated at 50° C. until there were no more droplets to obtain a yellow-brown viscous liquid, which was washed three times with ethyl acetate. The final product functional sulfonic acid dinuclear ionic liquid is obtained. Its structural formula is:

[0032]

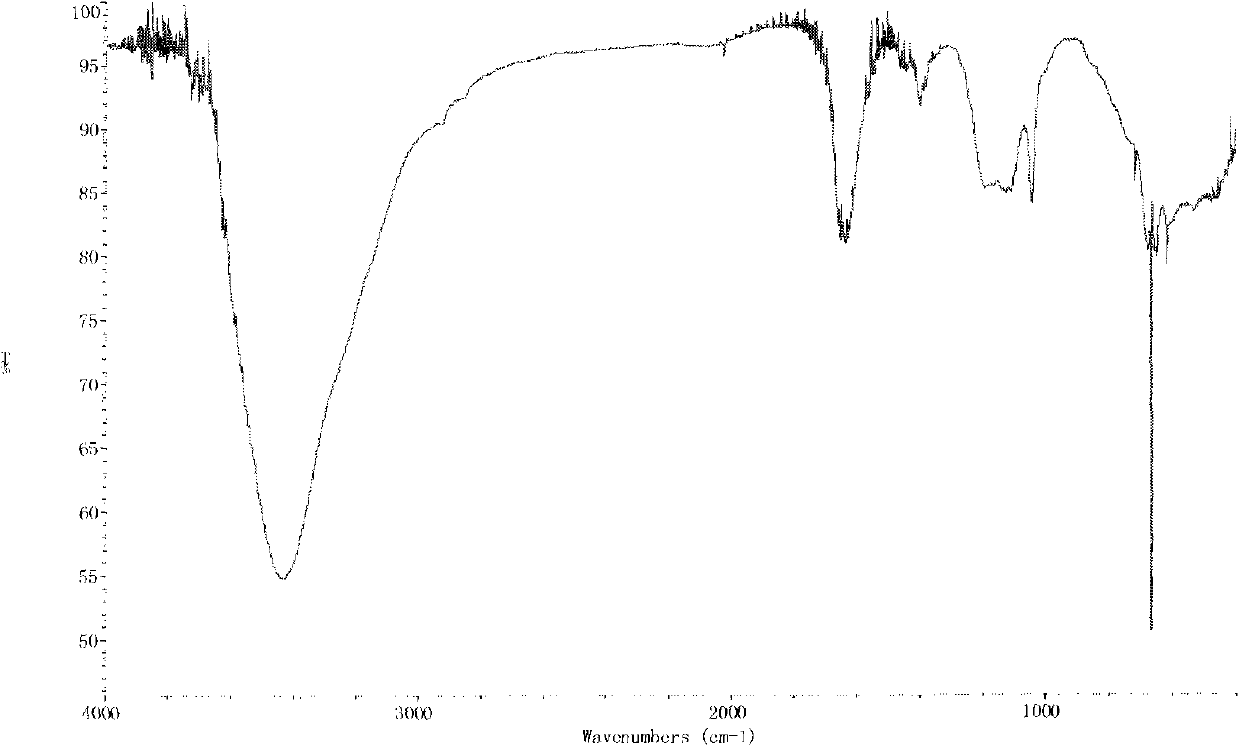

[0033] Where n=4, R=(CH 2 ) 3 , and its Fourier transform infrared characterization is shown in figure 1 As shown, it can be seen from the figure that through FTIR (KBr tablet) characterization, it is proved that ...

Embodiment 2

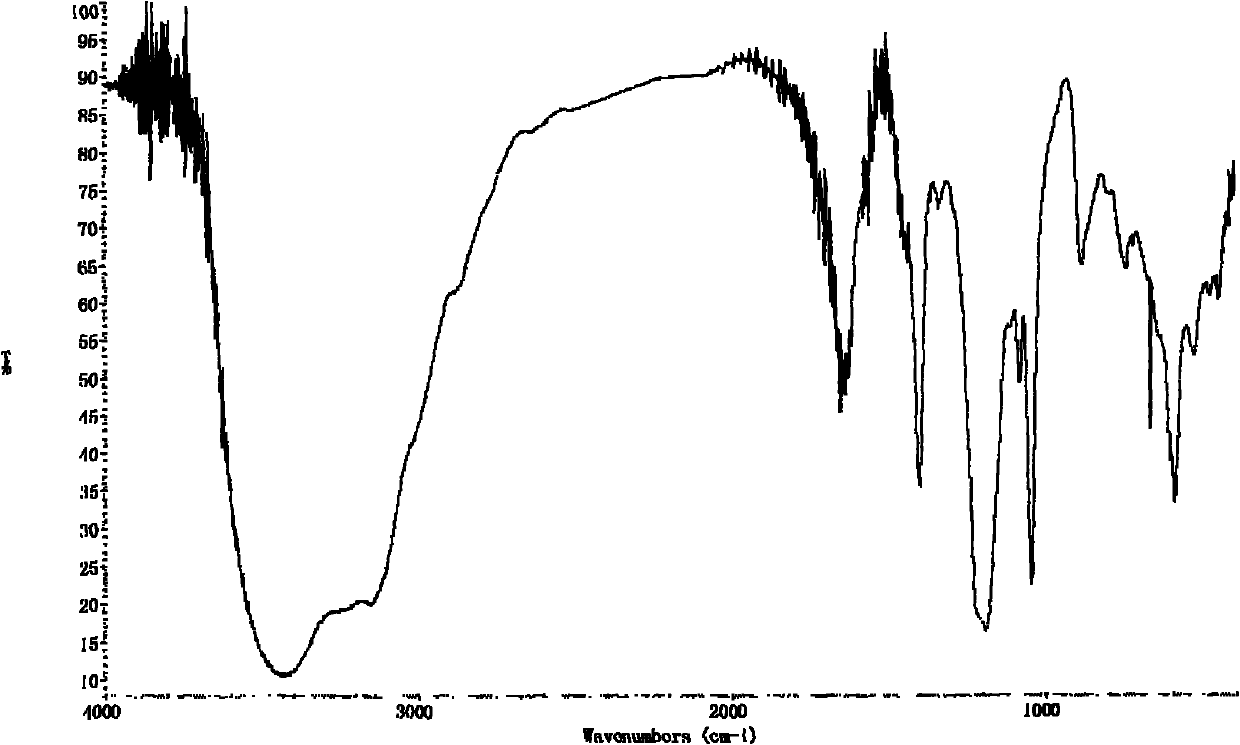

[0037] (A) Add 2.72g imidazole and 3.36g potassium ethylate to a three-necked flask, then add 50ml acetone, stir and reflux at 50°C for 10 hours, add 1.98g 1,2-dichloroethane, stir and reflux at 80°C for 18 hours, Filter under reduced pressure, take the liquid, pour the liquid into a three-necked flask, add 4.88g of 1,3-propane sultone, stir and reflux at 110°C for 9 hours, then add 4g of 98% concentrated sulfuric acid, stir and reflux at 110°C 6 hours. The liquid was poured into a rotary evaporator, and rotated at 70° C. until there were no more drops to obtain a yellow-brown viscous liquid, which was washed three times with ethyl acetate. The final product functional sulfonic acid dinuclear ionic liquid is obtained. Its structural formula is the same as embodiment 1, wherein n=2, R=(CH 2 ) 3 ; Its Fourier transform infrared characterization diagram is as follows figure 2 shown.

[0038] (B) put 59g of succinic acid and 67.5g of 1,4-butanediol into a 250ml flask, and ad...

Embodiment 3

[0041] (A) Catalyst preparation method is the same as embodiment 1, wherein, 1,4-dibromobutane is changed into 1,3-dibromopropane; 1,3-propane sultone is changed into 1,4-butanesulfone acid lactone.

[0042] (B) 59g of succinic acid and 54g of 1,4-butanediol are put into a 250ml flask, and the functionalized sulfonic acid dinuclear ionic liquid (n=3, R =(CH 2 ) 4 ), the add-on is 1g, adding the antioxidant phosphorous acid of 0.013g and the water-carrying agent toluene of 13g. Connect the water separator, thermometer and stirrer, then place in a heating mantle, fill with nitrogen, heat and stir vigorously. When the temperature reached 120°C, it was kept for 3 hours, and when the esterification reaction was completed, the temperature was raised to 210°C, and a vacuum of 70 Pa was maintained, while stirring was strengthened, and the reaction was carried out for 3 hours. Cool down to room temperature after the reaction, pour the product into a dumbbell-shaped mold to prepare ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com