Method for preparing nickel-cobalt-manganese ternary cathode material

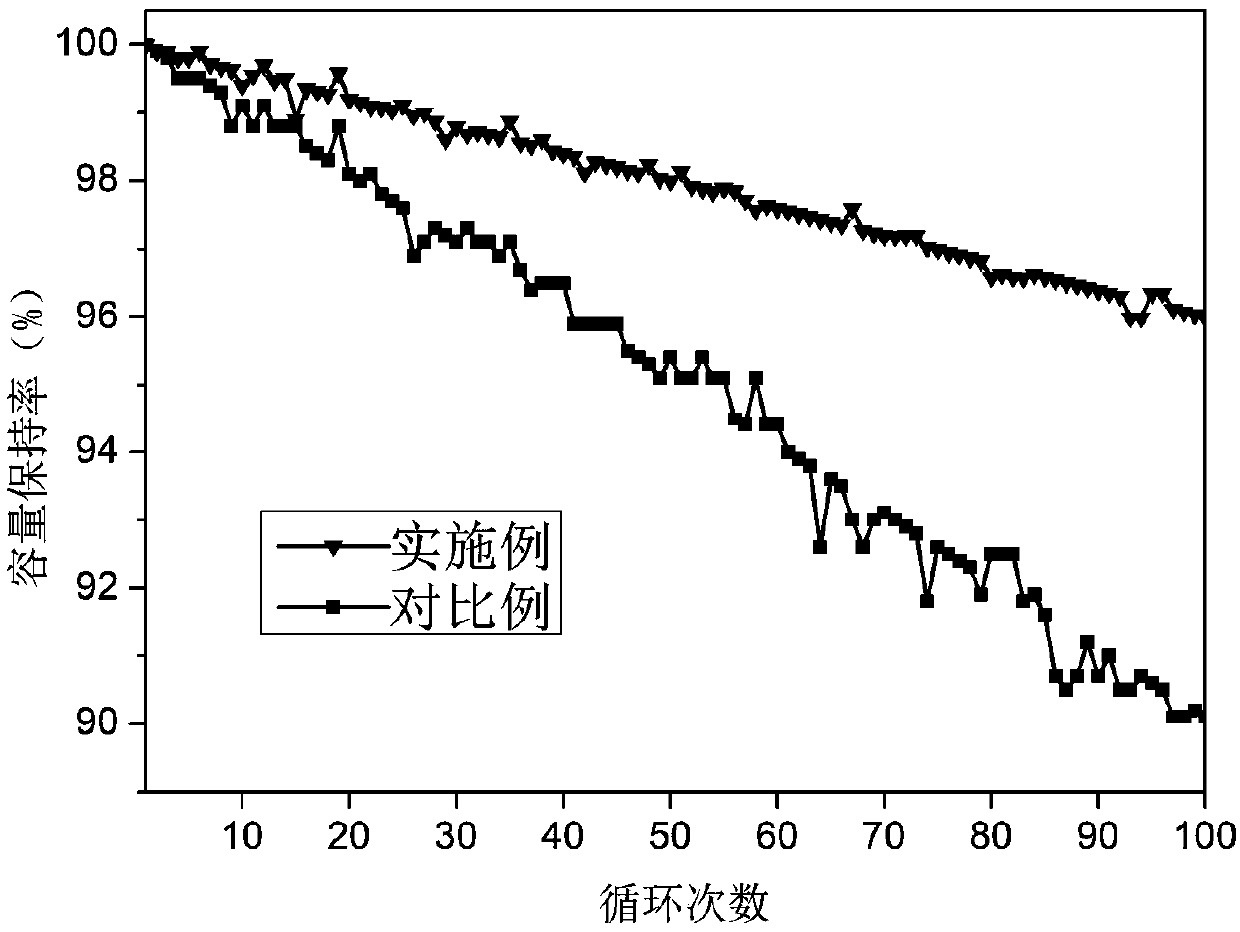

A positive electrode material, nickel-cobalt-manganese technology, applied in the field of preparation of nickel-cobalt-manganese ternary positive electrode materials, can solve the problems of reduced capacity, cycle performance, safety performance, low capacity, poor cycle performance, etc., and achieve outstanding electrochemical performance , High capacity retention rate, good processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] (1) A mixture of carbon dioxide and oxygen is introduced into the reaction device, wherein the volume concentration of carbon dioxide is 15%, and the molar ratio of carbon dioxide to cobalt-manganese is 0.6:1; the 2mol / L nickel-cobalt-manganese mixed solution is opened at a constant speed and fed into the liquid , wherein the molar coefficient ratio of nickel, cobalt and manganese is 78:11:11; at the same time, sodium hydroxide solution is added to control the pH value of the reaction solution to 10±0.1, and the feeding process is vigorously stirred at a stirring speed of 200rpm, and reacted at 80°C The α-type nickel-cobalt-manganese ternary precursor is prepared at high temperature, and its chemical formula is [Ni 2+ 0.78 co 3+ 0.11 mn 3+ 0.11 (OH) 2 ]CO 3 2- 0.11 , the α-type nickel-cobalt-manganese ternary precursor serves as the core of the nickel-cobalt-manganese ternary precursor with a core-shell structure.

[0026] (2) Suspend liquid addition, switch ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com