Solid electrolyte membrane, preparation method of solid electrolyte membrane, and lithium ion battery

A solid electrolyte membrane and electrolyte technology, applied in the manufacture of solid electrolytes, non-aqueous electrolyte batteries, electrolyte batteries, etc., can solve the problems of brittle and hard mechanical properties, difficult processing, no elasticity, etc., and achieve high ion conductivity, good The effect of processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

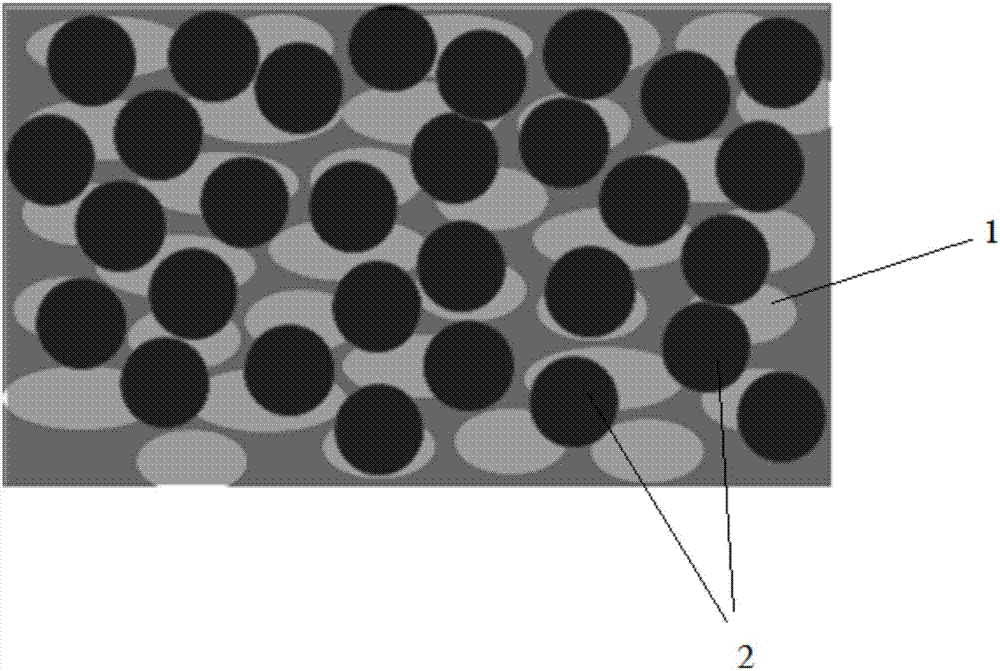

Image

Examples

preparation example Construction

[0029] The embodiment of the present application also discloses a method for preparing a solid electrolyte membrane, including steps:

[0030] (1), the phase separation method prepares the polymer matrix of three-dimensional network structure;

[0031] (2), the lithium inorganic solid electrolyte powder is mixed with a binder, and ball milled to form a uniformly dispersed mixed slurry;

[0032] (3) Soak the porous polymer matrix in the mixed slurry, pull it out, and dry it to obtain a solid electrolyte membrane.

[0033] Preferably, the step (1) includes: blending the polymer resin with a diluent, melting at high temperature to form a homogeneous solution → extrusion, casting into a film → cooling in a cooling bath, phase separation occurs → high temperature evaporation of solvent → high temperature two-way Stretch into a film → Provide a certain tension to ensure that the film will not shrink and extract and remove the diluent → Stretch the extracted film to further stretch ...

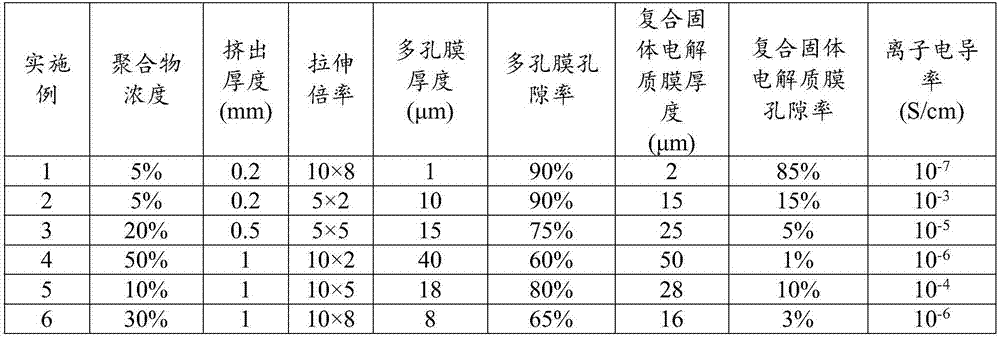

Embodiment 1

[0047] 5wt% (accounting for the percentage of total feeding mass) of ultra-high molecular weight polyethylene (UHMWPE, 1x10 6 , the melting point is 128°C, the glass transition temperature is -78°C) into the twin-screw extruder, and 95% (accounting for the percentage of the total feeding mass) of solid paraffin is added through the side feed port, and the mixture is heated at 150°C, Under the condition of 160 rev / min, melt and mix the resin. The mixed polyolefin melt was extruded through a die to form a polyolefin film with a thickness of 0.2mm, and the polyolefin film was directly cooled in a water bath at 20°C to obtain a porous polyolefin gel film. Fix the porous polyolefin gel film bidirectionally, place it in an oven at 120°C for 12 hours, and after the solvent is completely volatilized, stretch it longitudinally and transversely at 130°C in sequence, the stretching ratio = vertical × horizontal = 10 × 8, and the The thickness is 1 μm, the wire diameter is 0.002-0.5 μm, ...

Embodiment 2

[0051] 5wt% (accounting for the percentage of total feeding mass) of ultra-high molecular weight polyethylene (UHMWPE, 1 × 10 6 , the melting point is 128°C, the glass transition temperature is -78°C) into the twin-screw extruder, and 95% (accounting for the percentage of the total feeding mass) of solid paraffin is added through the side feed port, and the mixture is heated at 150°C, Under the condition of 160 rev / min, melt and mix the resin. The mixed polyolefin melt was extruded through a die to form a polyolefin film with a thickness of 0.2mm, and the polyolefin film was directly cooled in a water bath at 20°C to obtain a porous polyolefin gel film. Fix the porous polyolefin gel film bidirectionally, place it in an oven at 120°C for 12 hours, and after the solvent is completely volatilized, stretch it longitudinally and transversely at 130°C in sequence, and the stretching ratio = vertical × horizontal = 5 × 2, to obtain A three-dimensional sponge-like polyolefin porous m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com