Preparation of high-barrier nano modified PET composite material for packaging products

A technology of nano-modification and composite materials, applied in the field of materials, can solve problems such as high cost, difficult product recycling, complex processing technology, etc., and achieve good processing performance, easy processing and recycling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

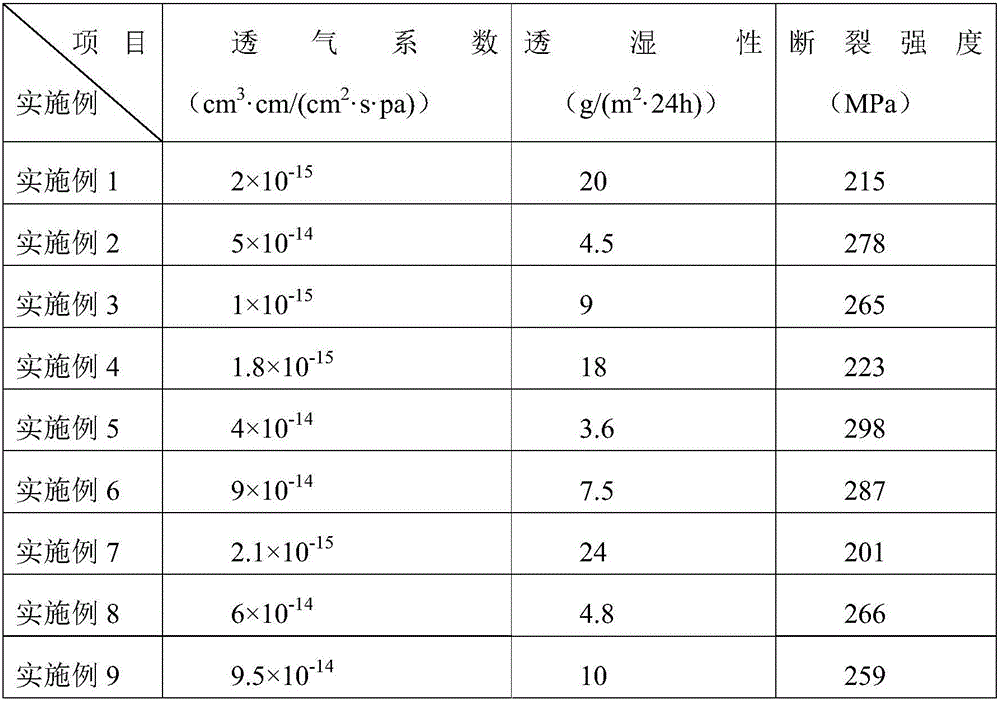

Examples

Embodiment 1

[0025] Step 1) Preparation of modified graphene: soak 5-10 layers of graphene in 0.1% sodium dodecylsulfonate aqueous solution for 24 hours, and vacuum dry at 50° C. for 48 hours to obtain modified graphene.

[0026] Step 2) preparation of graphene / PET composite material by in-situ polymerization: first the modified graphene obtained in step 1) is ultrasonically dispersed in ethylene glycol, and the ethylene glycol solution of modified graphene of 0.1mg / ml is prepared , Synthesis of graphene / PET composites by transesterification. The specific preparation process is as follows: First, nitrogen gas is passed through the four-necked bottle for 30 minutes, then terephthalic acid ester and ethylene glycol are added to the four-necked bottle at a molar ratio of 1:2, and terephthalic acid ester is added to add mass of 0.03% transesterification catalyst Zn(OAc) 2 , under the protection of nitrogen, the temperature was raised to 200 ° C, after the terephthalate was completely dissolve...

Embodiment 2

[0029] Step 1) Preparation of modified graphene: soak 5-10 layers of graphene in an aqueous solution of polyvinylpyrrolidone with a mass concentration of 0.1% for 24 hours, and vacuum-dry at 50° C. for 48 hours to obtain modified graphene.

[0030] Step 2) preparation of graphene / PET composite material by in-situ polymerization: first the modified graphene obtained in step 1) is ultrasonically dispersed in ethylene glycol, and the ethylene glycol solution of modified graphene of 0.15mg / ml is prepared , Synthesis of graphene / PET composites by transesterification. The specific preparation process is as follows: First, nitrogen gas is passed through the four-necked bottle for 30 minutes, then terephthalic acid ester and ethylene glycol are added to the four-necked bottle at a molar ratio of 1:2, and terephthalic acid ester is added to add mass of 0.05% transesterification catalyst Zn(OAc) 2 , under the protection of nitrogen, the temperature was raised to 200 ° C, after the tere...

Embodiment 3

[0033] Step 1) Preparation of modified graphene: soak 5-10 layers of graphene in 0.1% cetyltrimethylammonium bromide aqueous solution for 24 hours, and vacuum dry at 50° C. for 48 hours to obtain modified graphene.

[0034] Step 2) Preparation of graphene / PET composite material by melt blending method: first, put the PET masterbatch and the modified graphene powder obtained in step 1) into a drying oven, and dry at 100°C. Then the modified graphene powder of PET masterbatch and 0.3wt% of the total weight of the composite material is placed in a dry mixer and mixed uniformly, and the mixed material is added to the mixer to be melted and kneaded and then extruded to prepare A nano-modified PET composite material is obtained.

[0035] Step 3) The graphene-modified PET composite material obtained in step 2) is prepared into a single-layer high-barrier packaging product through processing techniques such as a one-step blow molding method or a two-step blow molding method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com