Modified polyethylene and easy-to-uncover suppositorium packaging film

A polyethylene and polyethylene layer technology, applied in the field of plastic packaging films, can solve the problems of inconvenience in use, and achieve the effects of good barrier performance, convenient use and good processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

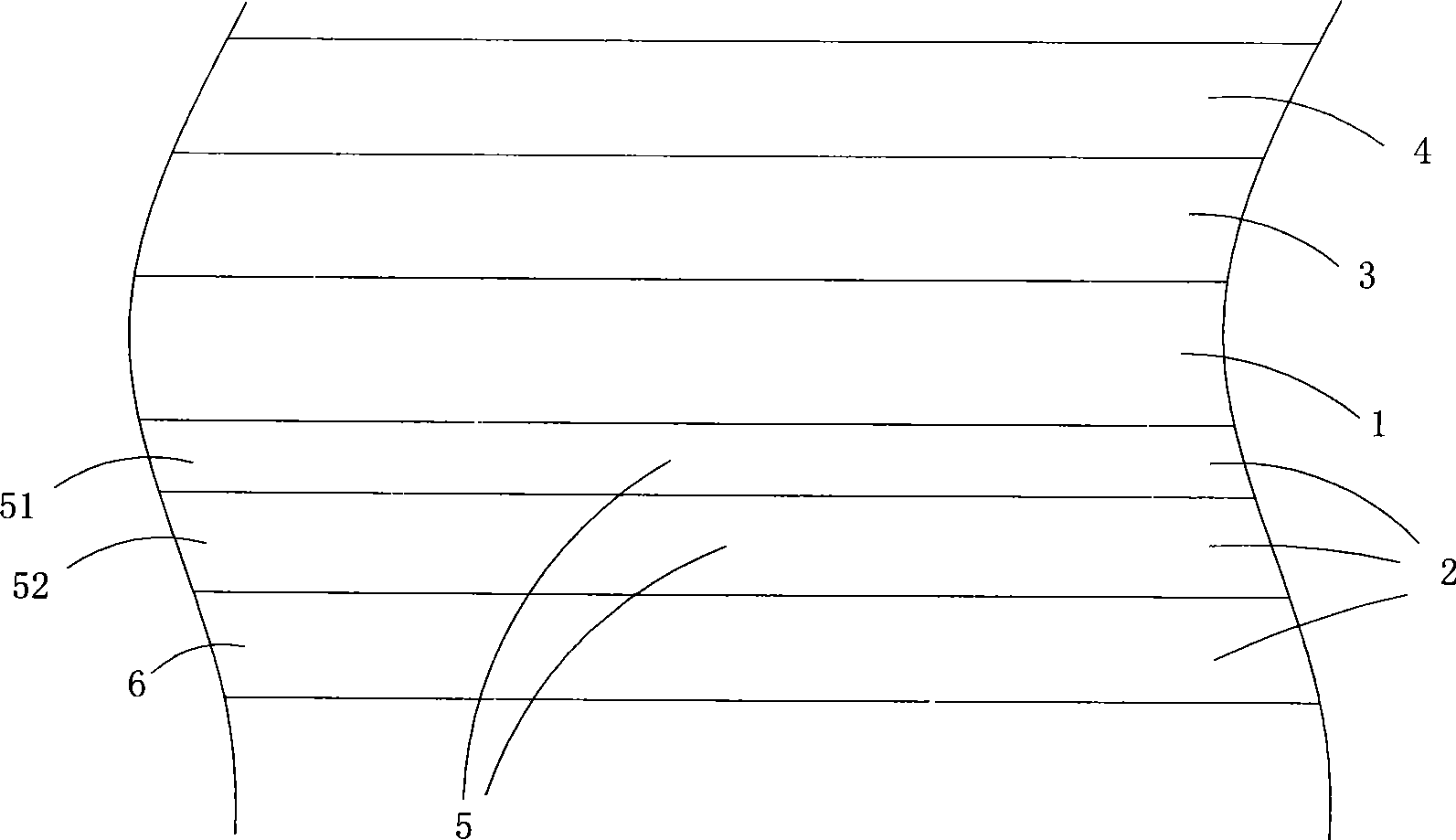

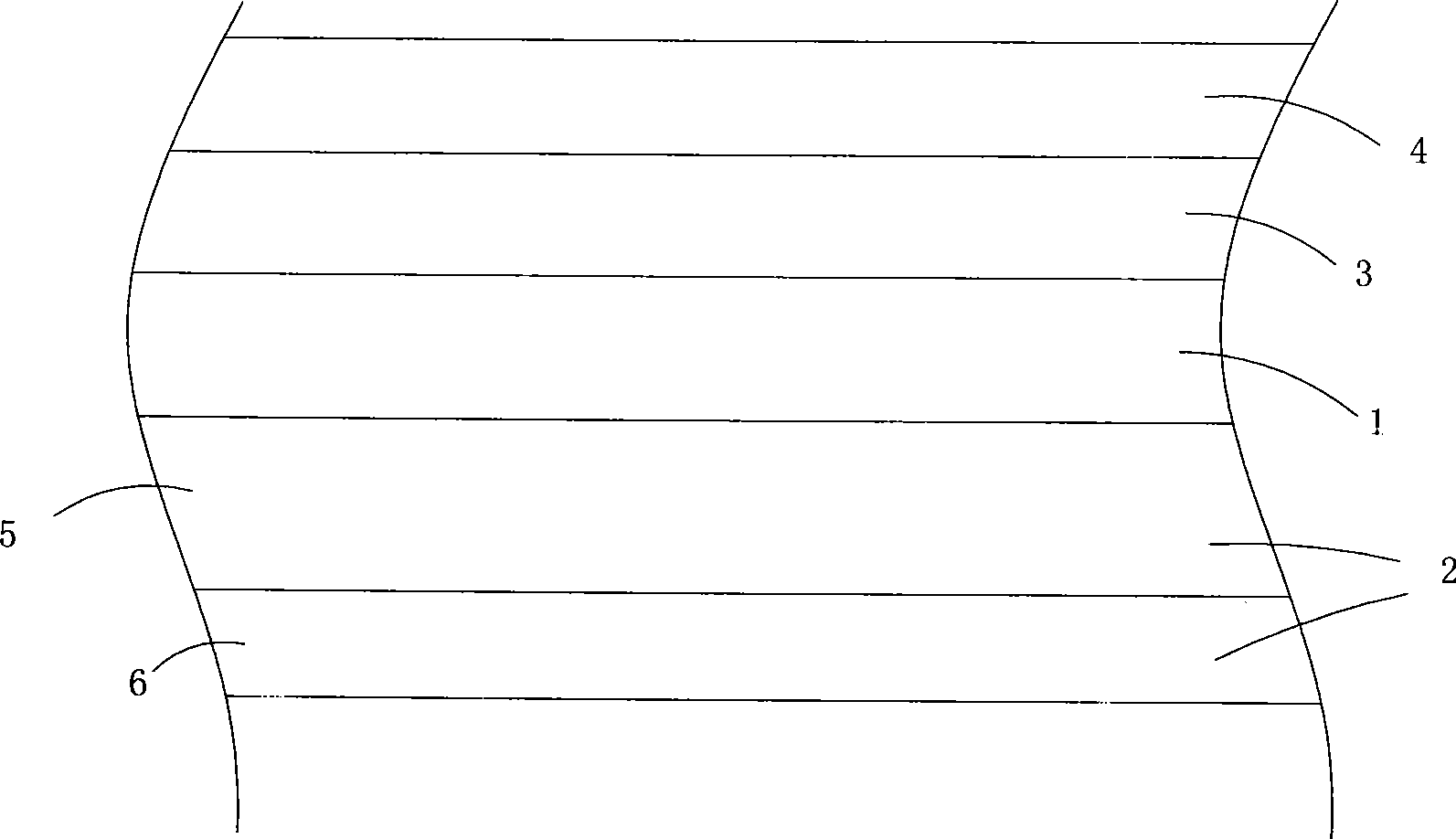

Image

Examples

Embodiment 1

[0025] (embodiment 1, modified polyethylene)

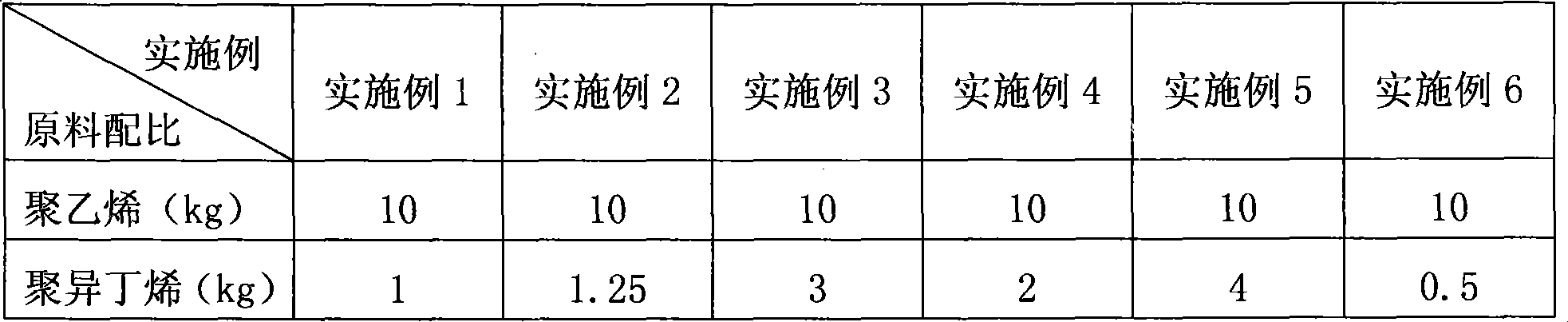

[0026] This embodiment is a modified polyethylene, its raw materials include: polyethylene: 10 kilograms; and polyisobutylene used to reduce the bonding performance of the polyethylene: 0.5 kilograms; the parts by weight are 10:0.5 . The polyethylene is selected from the polyethylene produced by Hongtai Plastic Raw Materials Co., Ltd., and the polyisobutylene is selected from medium and high molecular weight polyisobutylene with a brand name of BASF B15. After mixing the above-mentioned raw materials with good proportions, they are formed by blown film method in a blown film machine. The specific formula of this embodiment is shown in Table 1.

Embodiment 2 to Embodiment 6

[0027] (embodiment 2 to embodiment 6, modified polyethylene)

[0028] Each embodiment in embodiment 2 to embodiment 6 is basically the same as embodiment 1, the difference is: the proportioning of raw materials used in each embodiment in embodiment 2 to embodiment 6 is different, see table 1 for details.

[0029] Table 1

[0030]

Embodiment 7 to Embodiment 12

[0031] (Example 7 to Example 12, modified polyethylene)

[0032] Each embodiment in embodiment 7 to embodiment 12 is substantially the same as embodiment 1, and difference is: the raw material used in each embodiment in embodiment 7 to embodiment 12 is polyethylene and polyn-butylene, in addition, each embodiment The ratio of raw materials in is also slightly different, see Table 2 for details.

[0033]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Peel strength | aaaaa | aaaaa |

| Peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com