Ferulic acid-araboxylan copolymer antibacterial film as well as preparation method and application thereof

A technology of arabinoxylan and ferulic acid, applied in the field of food chemistry, can solve the problems of prolonging the shelf life of rainbow trout fillets, and achieve good barrier properties and good antibacterial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The present invention also proposes a preparation method of a ferulic acid-arabinoxylan copolymer antibacterial film, which specifically includes the following steps:

[0041] (1) The solids are calculated in parts by mass, and the liquids are calculated in parts by volume, and each raw material is prepared, and the consumption of each raw material is: 0.5-0.8 parts of sodium alginate, 30-40 parts of distilled water, 0.3-0.6 parts of glycerin, and the mass concentration is 10 mg 10-15 parts of ferulic acid-arabinoxylan copolymer / mL;

[0042] (2) disperse sodium alginate in distilled water and stir to obtain sodium alginate solution, and the solution is a transparent homogeneous solution;

[0043] (3) add glycerol in the described sodium alginate solution, stir, obtain sodium alginate-glycerol mixed solution;

[0044] (4) add ferulic acid-arabinoxylan copolymer to the sodium alginate-glycerol mixed solution, stir to obtain the film mixed solution;

[0045] (5) stirring...

Embodiment 1

[0051] A ferulic acid-arabinoxylan copolymer antibacterial film proposed in this embodiment includes the following raw materials: 0.6 part of sodium alginate, 30 parts of distilled water, 0.5 part of glycerin, and ferulic acid-arabino with a mass concentration of 10 mg / mL 10 parts of xylan copolymer.

[0052] Prepare as follows:

[0053] (1) The dosage of each raw material is: 0.6 part of sodium alginate, 30 parts of distilled water, 0.5 part of glycerin, and 10 parts of ferulic acid-arabinoxylan copolymer with a mass concentration of 10 mg / mL.

[0054] (2) disperse sodium alginate in distilled water and stir to obtain sodium alginate solution;

[0055] (3) add glycerol in the described sodium alginate solution, stir, obtain sodium alginate-glycerol mixed solution;

[0056] (4) add ferulic acid-arabinoxylan copolymer to the sodium alginate-glycerol mixed solution, stir to obtain the film mixed solution;

[0057] (5) stirring the film mixture in a water bath at 30°C for 30mi...

Embodiment 2

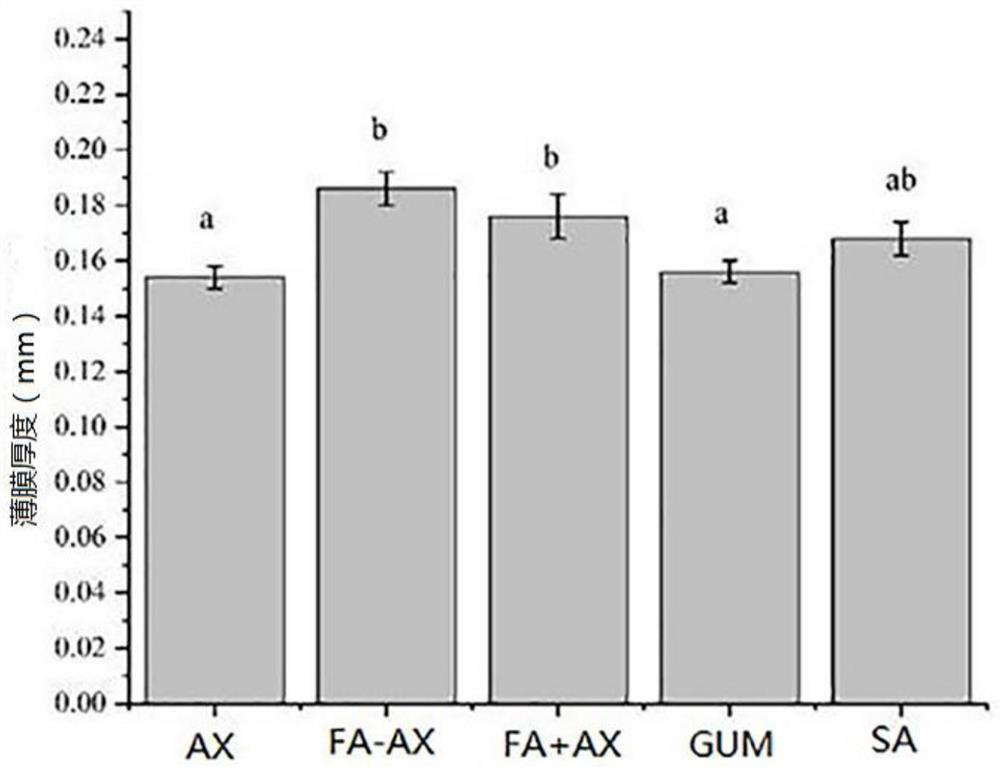

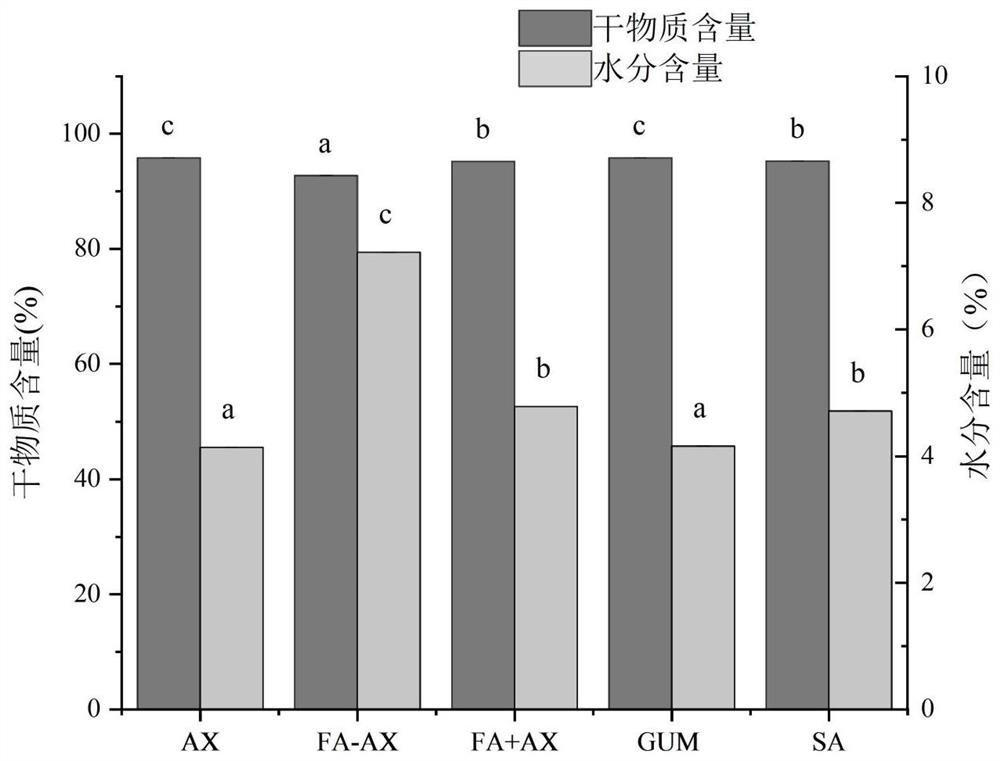

[0106] In this example, the films obtained in Example 1 and Comparative Examples 1-4 (or some of the comparative examples) were used as samples. rate, elongation at break, tensile stress and antimicrobial properties were tested. The films prepared in Example 1 and Comparative Examples 1-4 were named FA-AX film (representing sample 1 in Example 1), AX film (representing sample 2 in Comparative Example 1), and SA film (representing Comparative Example 1), respectively. 2), FA+AX film (representing sample 4 in comparative example 3), GUM film (representing sample 5 in comparative example 4).

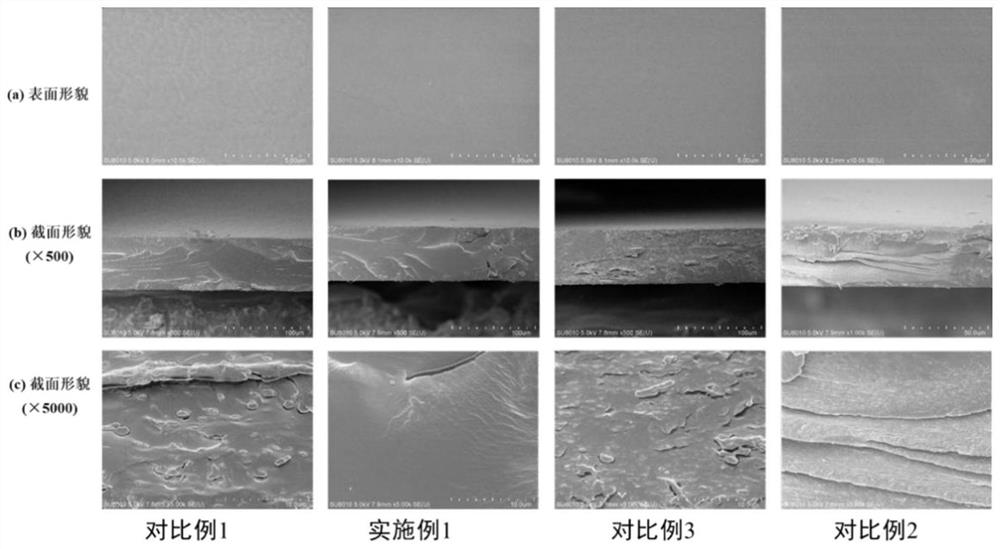

[0107] 1. Morphological determination

[0108] The surface and cross-section of FA-AX thin film, AX thin film, SA thin film and FA+AX thin film samples were scanned by electron microscope respectively. 500, c×5000) such as figure 1 shown.

[0109] from figure 1 It can be seen that the FA-AX film is a large sheet-like molecule. There is no obvious arabinoxylan and ferulic acid structure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com