Fully-biodegradable high-barrier polyamide-based composite film material and preparation method thereof

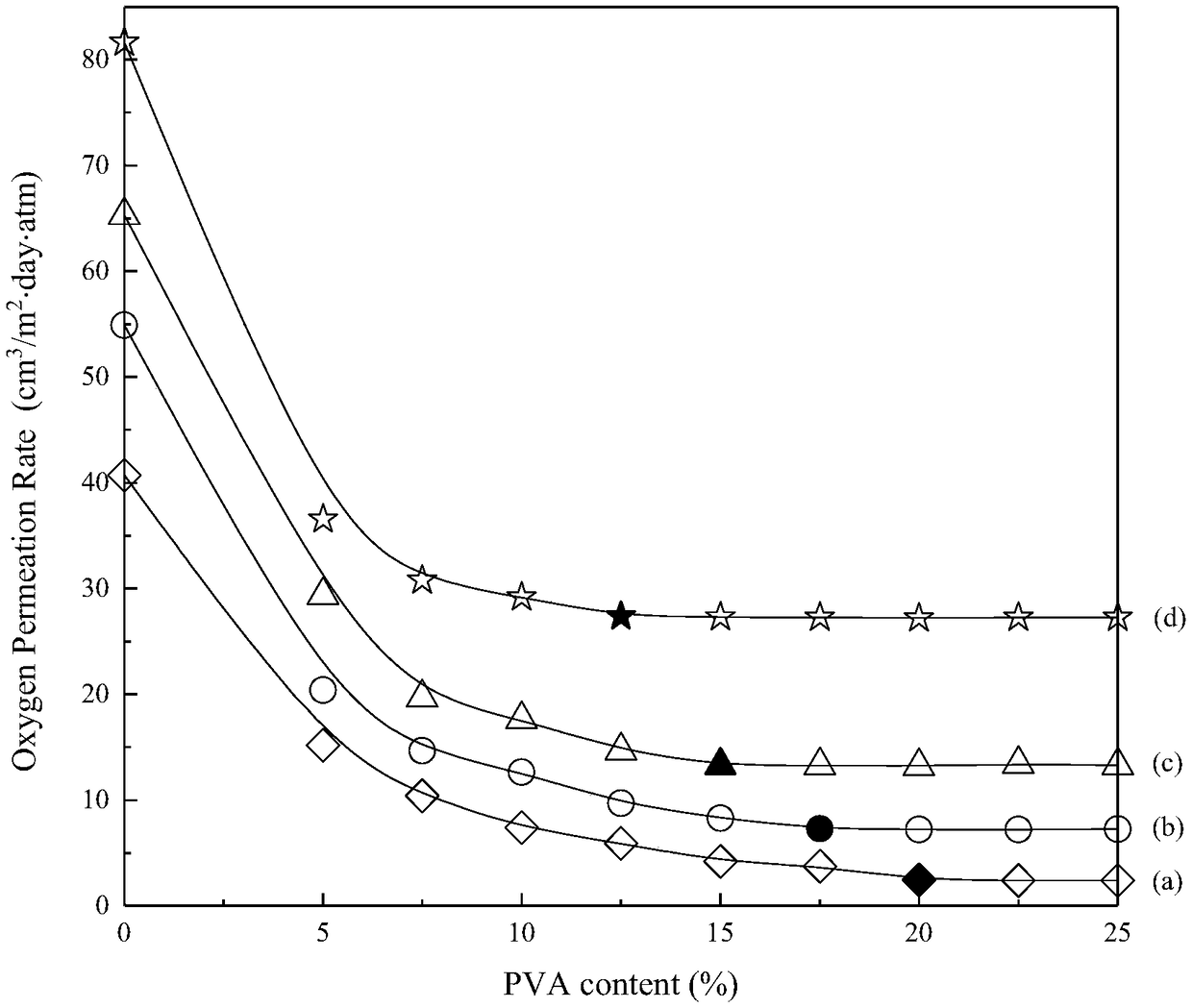

A polyamide-based and biodegradable technology is applied in the field of completely biodegradable high-barrier polyamide-based composite film materials and their preparation, and can solve the problem of uneven product opaque color, poor processing fluidity of polymer plastics, and excessive crystal points. and other problems, to achieve the effect of low price, good processability and good biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1) each component is by mass ratio

[0027] Nylon 9: 95 parts;

[0028] Starch-based resin: 4.79 parts;

[0029] Polyvinyl alcohol (molecular weight 10000, degree of alcoholysis 98): 0.1 part;

[0030] Polyol oligomer plasticizer: 0.1 part;

[0031] Antioxidant 1098: 0.01 part;

[0032] Mix well with a high-speed mixer, and dry in vacuum at 80°C for 12 hours.

[0033] 2) Use a twin-screw extruder to extrude and granulate the blend, and set the temperature of each heating section as follows: the first section is 220°C, the second section is 240°C, the third section is 260°C, and the fourth section is 280°C , 300°C in the fifth section.

[0034] 3) Vacuum drying the granulated completely biodegradable high-barrier polyamide-based composite material at 50° C. for 24 hours to make the moisture content ≤ 0.1 wt % to obtain a fully biodegradable high-barrier polyamide-based composite material masterbatch.

[0035] 4) Use multi-layer co-extrusion blown film equipment to ...

Embodiment 2

[0037] 1) each component is by mass ratio

[0038] Nylon 10: 90 parts;

[0039] Cellulose: 2.99 parts;

[0040] Polyvinyl alcohol (molecular weight 50000, degree of alcoholysis 98): 5 parts;

[0041] Chlorine compound plasticizer: 2 parts;

[0042] Antioxidant 1010: 0.01 parts;

[0043] Mix well with a high-speed mixer, and dry in vacuum at 80°C for 12 hours.

[0044] 2) Use a twin-screw extruder to extrude and granulate the blend, and set the temperature of each heating section as follows: the first section is 250°C, the second section is 270°C, the third section is 290°C, and the fourth section is 310°C , 330°C in the fifth section.

[0045] 3) Vacuum-dry the granulated fully biodegradable high-barrier polyamide-based composite material at 80° C. for 12 hours to make the moisture content ≤ 0.1 wt % to obtain a fully biodegradable high-barrier polyamide-based composite material masterbatch.

[0046] 4) Use multi-layer co-extrusion blown film equipment to blow the master...

Embodiment 3

[0048] 1) each component is by mass ratio

[0049] Nylon 11: 65 parts;

[0050] Starch-based resin: 5 parts;

[0051] Cellulose: 2.8 parts;

[0052] Polyvinyl alcohol (molecular weight 100000, degree of alcoholysis 98.2): 20 parts;

[0053] Amide plasticizer: 2 parts;

[0054] Antioxidant 245: 0.2 parts;

[0055] Mix well with a high-speed mixer, and dry in vacuum at 80°C for 12 hours.

[0056] 2) Use a twin-screw extruder to extrude and granulate the blend, and set the temperature of each heating section as follows: the first section is 150°C, the second section is 160°C, the third section is 170°C, and the fourth section is 180°C , 190°C in the fifth section.

[0057] 3) Vacuum drying the granulated completely biodegradable high-barrier polyamide-based composite material at 50° C. for 24 hours to make the moisture content ≤ 0.1 wt % to obtain a fully biodegradable high-barrier polyamide-based composite material masterbatch.

[0058] 4) Use multi-layer co-extrusion blown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com