Patents

Literature

46results about How to "Realize resource recovery and reuse" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for removing phthalate ester in water body by utilizing solid base catalyst

ActiveCN101665298AHarm reductionRealize resource recovery and reuseOxygen-containing compound preparationOrganic compound preparationChemistryChloride sodium

The invention discloses a method for removing phthalate ester in a water body by utilizing a solid base catalyst, which belongs to the field of wastewater treatment by resin. The method comprises the following steps of: firstly filtering the water body containing phthalate ester pollutants for removing suspended solids in the water body; then leading the obtained filtrate to pass through an absorption tower which is filled with anion exchange resin containing strong base groups; stopping the absorption when the absorption achieves a leakage point, using mixed solution of sodium hydroxide and sodium chloride for carrying out the desorption, and using sodium hydroxide solution for carrying out the regeneration on the resin after the desorption; and obtaining desorption solution which contains sodium phthalate and can be repeatedly recycled, using hydrochloric acid for neutralizing the desorption solution, and recycling phthalic acid after recrystallization. The method adopts the strong base anion exchange resin as the solid base catalyst, deeply removes the phthalate ester pollutants in the water body by catalytic hydrolysis and acid-base absorption, separates and recycles the phthalic acid while reducing the harm of the phthalate ester pollutants and realizes the recycling and the reutilization of resources, the resin has good regeneration performance and can be used repeatedly.

Owner:NANJING UNIV

Method for treating wastewater from production of methyl naphthol and reclaiming methyl naphthol and methyl naphthylamine

InactiveCN1884123APromote regenerationRealize resource recovery and reuseSolid sorbent liquid separationWater/sewage treatment by neutralisationDesorptionVolumetric Mass Density

The invention discloses a harnessing method of naphthol manufacturing waste water and recycling method of naphthol and a-haphthylamine, which comprises the following steps: filtering naphthol manufacturing waste water; removing suspension; making filtrate through adsorption tower with large-hole resin; stopping adsorbing until the adsorption reaches leakage point; adopting carbinol or alcohol water solution as desorption agent to regenerate; obtaining alcoholic solution of naphthol and a-haphthylamine as desorption agent; rectifying the desorbed alcoholic solution; returning remained composition of naphthol and a-haphthylamine in the dehydrating procedure of original manufacturing process. The invention makes naphthol density less than 3mg / L, a-haphthylamine density less than 2mg / L and COD less than 100mg / L, which recycles resource to reduce manufacturing cost obviously.

Owner:NANJING UNIV

Technology for reclaiming low-concentration formaldehyde from pesticide wastewater through ionic liquid supported liquid membrane pervaporation-distillation coupling technology

InactiveCN102001924ARealize resource recovery and reuseSolve the emission problemMultistage water/sewage treatmentCarbonyl compound separation/purificationPtru catalystMembrane permeabilization

The invention relates to technology for reclaiming low-concentration formaldehyde from pesticide wastewater through ionic liquid supported liquid membrane pervaporation-distillation coupling technology. The technology comprises the following steps that: (1) a pervaporation device provided with an ionic liquid supported liquid membrane is adopted to perform pre-enrichment of low-concentration formaldehyde-containing pesticide wastewater on a transmission side; and (2) the formaldehyde wastewater subjected to pre-enrichment enters the middle part of a rectification column, a catalytic reaction is performed in a reaction section of the rectification column filled with a solid acid catalyst, the stay time is reasonably controlled in a way of outside pump circulation to allow free formaldehyde obtained by depolymerizing polymeric formaldehyde to enter a rectification section to be concentrated, high-concentration formaldehyde solution is obtained, and wastewater solution from which the formaldehyde is removed is obtained in a stripping section. Because the formaldehyde solution is subjected to pre-enrichment by the pervaporation device provided with the ionic liquid supported liquid membrane and is then separated through rectification, compared with the single rectification, the technology can greatly save energy consumption and reduce the cost. Therefore, the technology is more economic and reasonable.

Owner:NANJING UNIV

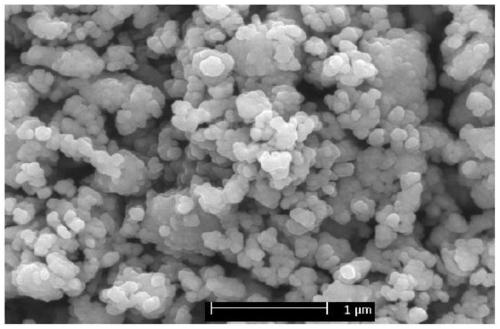

Method for preparing V2O5 nano powder by using vanadium redox battery failure electrolyte

InactiveCN109721101AHigh purityIncrease added valueNanotechnologyVanadium oxidesVanadium redox batterySURFACTANT BLEND

The invention belongs to the technical field of vanadium extraction, and particularly relates to a method for preparing V2O5 nano powder by using a vanadium redox battery failure electrolyte. The technical problem to be solved by the invention is to provide the method for preparing the V2O5 nanopowder by using the vanadium redox battery failure electrolyte. The method comprises the following steps: performing oxidization on the vanadium redox battery failure positive-electrode electrolyte, performing dilution, adding a surfactant, and performing a closed heat-preservation reaction at 100-120 DEG C, so as to obtain the V2O5 nano powder. The method provided by the invention fully utilizes waste resources, and the recovered vanadium pentoxide nano powder has high purity and a high yield.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD

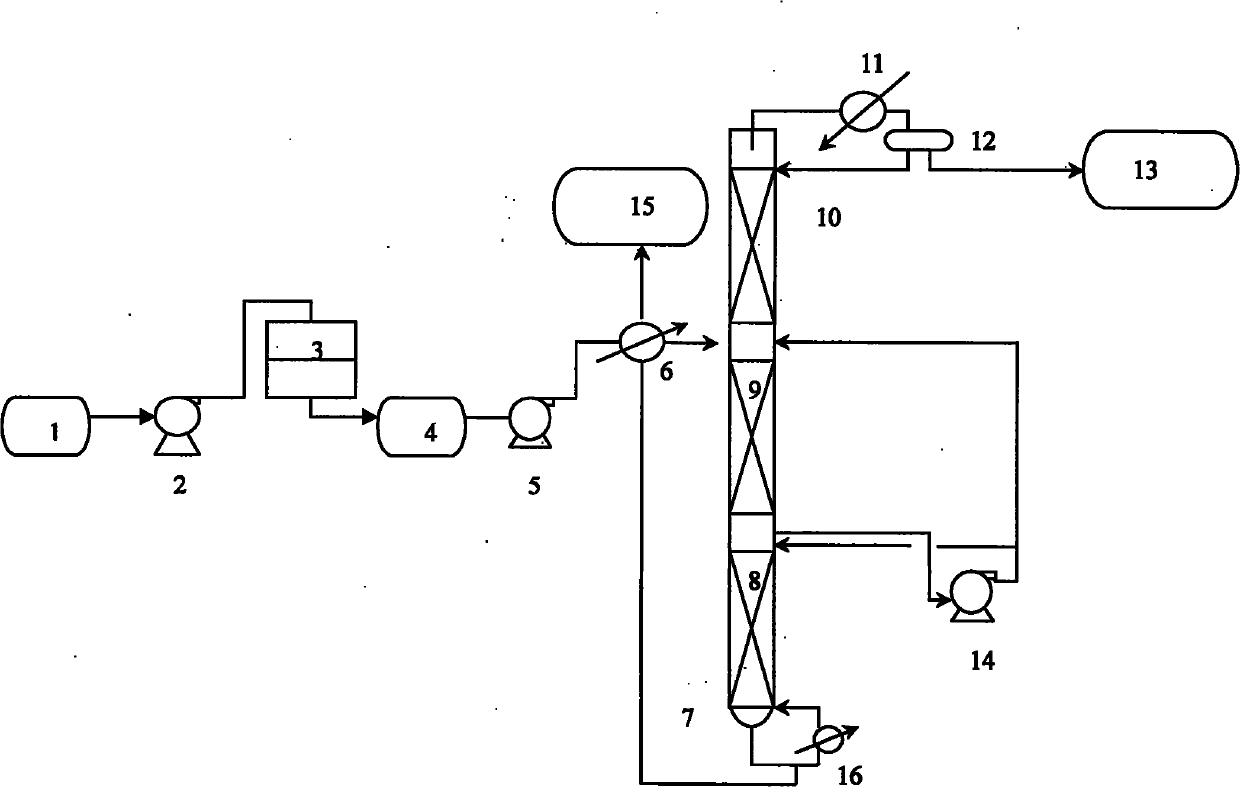

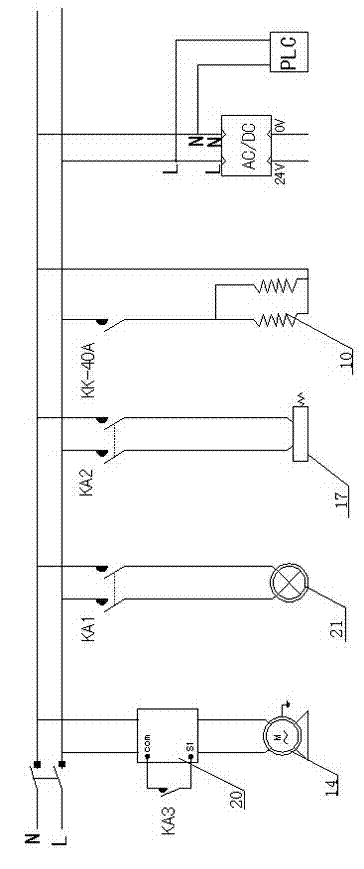

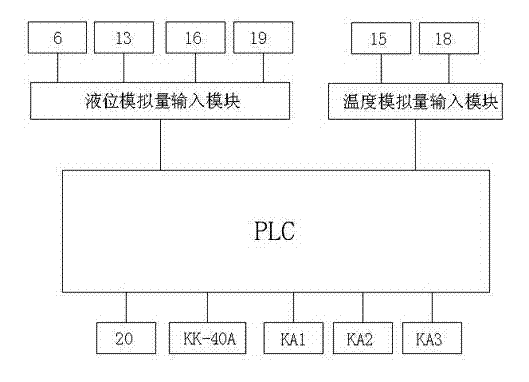

System for automatically recycling acetic acid from ceramic leaching liquid waste

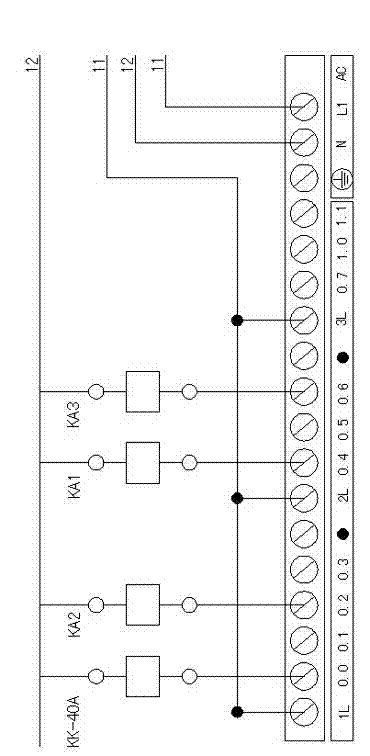

ActiveCN103288621AFully automatedRealize intelligent controlCarboxylic compound separation/purificationLiquid wasteProgrammable logic controller

Owner:中华人民共和国唐山出入境检验检疫局

Acid etching wastewater treatment and recycling system

ActiveCN108893742ARealize resource recovery and reuseTake advantage ofPhotography auxillary processesProcess efficiency improvementAcid etchingElectrolysis

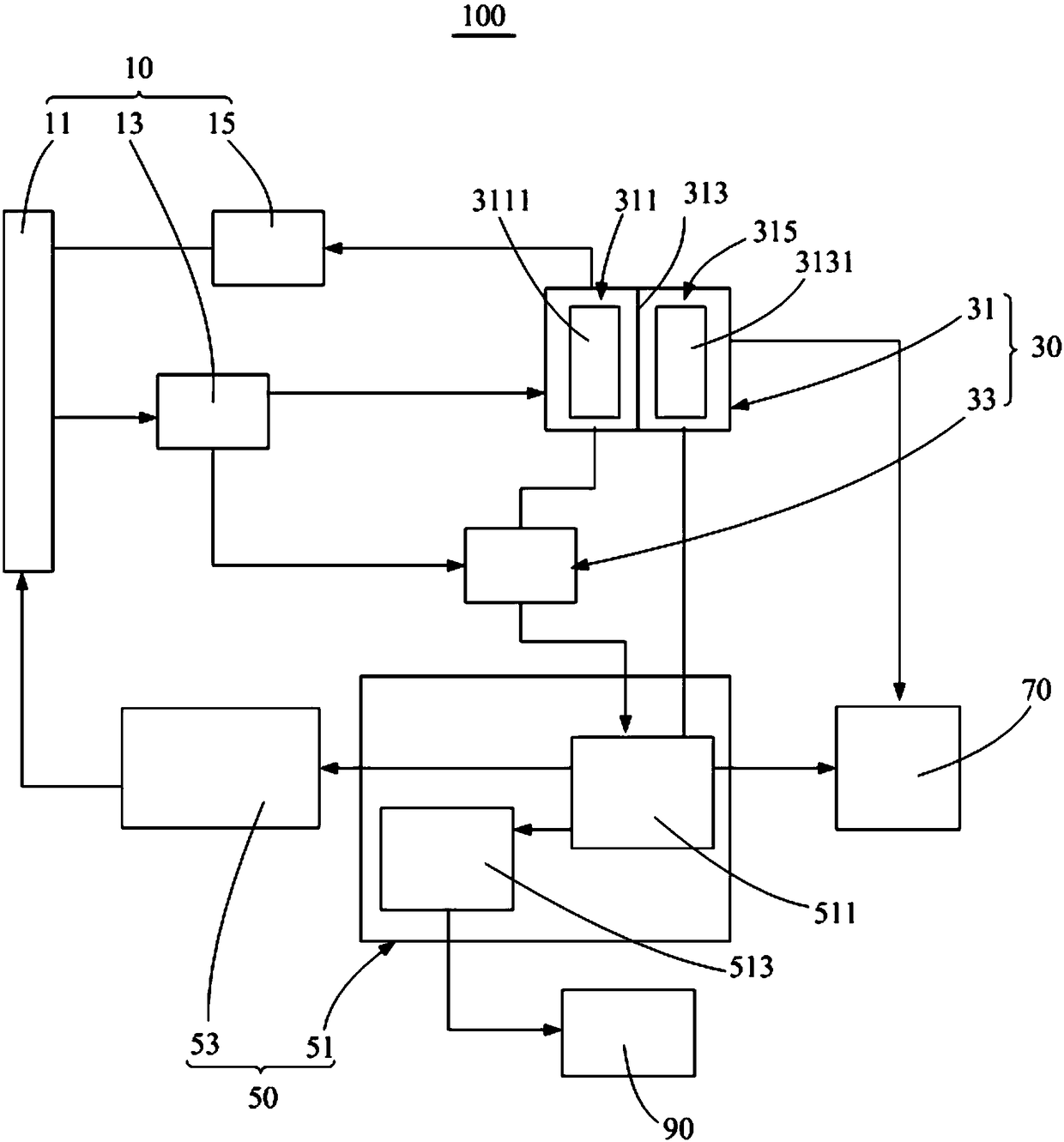

The invention discloses an acid etching wastewater treatment and recycling system, comprising: an etching station, wherein the etching station is provided with an etching machine cylinder and a wastewater transfer cylinder, and the wastewater transfer cylinder is communicated with the etching machine cylinder; an electrolytic station provided with an electrolytic device that includes an anodic chamber and a cathodic chamber divided by a diaphragm, wherein both the cathodic chamber and the anodic chamber are communicated with the wastewater transfer cylinder; a regeneration station provided with a regenerated liquid collection device and a regenerated sub-liquid blending cylinder communicated with each other, wherein the regenerated liquid collection device is communicated with the anodic chamber, and the regenerated sub-liquid blending cylinder is communicated with the etching machine cylinder. The acid etching wastewater treatment and recycling system can impart higher etching rate inan etching procedure to an etching liquid from regenerated and recycled acid etching wastewater.

Owner:深圳市祺鑫环保科技有限公司

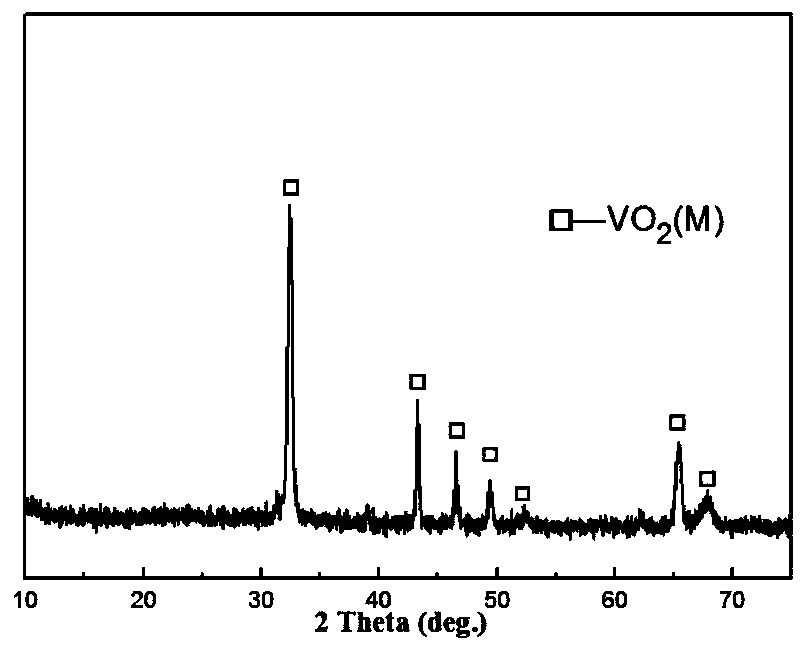

Method for preparing M-phase VO2 by using inactivated vanadium battery positive electrolyte

The invention discloses a method for preparing M-phase VO2 by using an inactivated vanadium battery positive electrolyte. The method belongs to the technical field of vanadium dioxide, and comprises the following steps: (1) adding a reducing agent into the anode electrolyte of the failed vanadium battery to carry out reduction reaction, adding a precipitant into the electrolyte after the reductionreaction is finished to adjust the pH value to 3-6, carrying out solid-liquid separation, and washing the solid product to obtain a black precipitate; and (2) calcining the black precipitate to obtain VO2 powder. According to the method, the inactivated vanadium battery electrolyte is used as a raw material, so that resource recycling is realized, and the preparation cost of VO2 is reduced; meanwhile, the method is simple in process and suitable for industrial application; and the prepared VO2 is high in purity, high in additional value and high in crystallinity, and can be widely applied tothe fields of intelligent windows, photoelectric switches, thermistors and the like.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD

Processing process of dioctyl terephthalate

InactiveCN106278884AReduce usageRealize resource recovery and reuseOrganic compound preparationCarboxylic acid esters separation/purificationIsooctyl alcoholTetraisopropyl titanate

The invention discloses a processing process of dioctyl terephthalate. The processing process comprises the following steps that 1, terephthalic acid and isooctyl alcohol with the weight ratio being 1:(2-3) are adopted as main raw materials, an esterification reaction is carried out at normal pressure and the temperature of 120 DEG C to 230 DEG C, after reacting is carried out for 8 h to 10 h, the temperature is raised to 225 DEG C to 235 DEG C, a tetraisopropyl titanate catalyst is added, the amount of the catalyst is 0.05% of the sum of the amount of the main raw materials, and a primary product is obtained through reacting; 2, the primary product is subjected to vacuum flashing treatment; 3, a sodium carbonate solution is added into the primary product in the step 2 for reacting for 10 min, then water is continuously added for 15 min for washing, and drainage is carried out after sedimentation is carried out for 40 min; 4, after the primary product is subjected to acidity adjustment, water is introduced into a reaction still, the primary product is vaporized to form azeotrope with excessive alcohol, the product is discharged after condensation, and dealcoholization is carried out; 5, finally, finished dioctyl terephthalate is obtained through filtering. The process is simple in condition and high in finished product quality, and the reaction process is environmentally friendly.

Owner:浙江弘博新材料科技有限公司

Method and application for solid-liquid separation treatment of waste drilling fluid

InactiveCN108640218ASimple processReduce contentWaste water treatment from quariesWater/sewage treatment by centrifugal separationFiltrationResource utilization

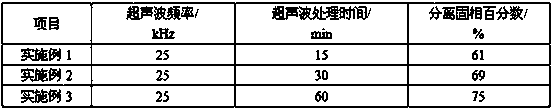

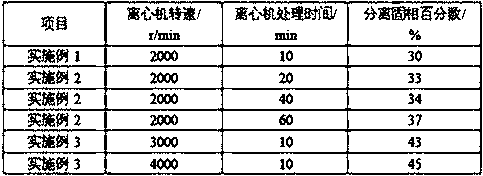

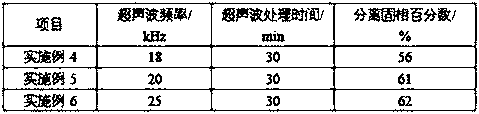

The invention relates to a method and an application for solid-liquid separation treatment of a waste drilling fluid. The technical scheme comprises three steps of ultrasonic wave treatment, centrifugation of a waste drilling fluid, and separation of solid phase and liquid phase. The ultrasonic treatment time is 15-60 min, the ultrasonic wave treatment frequency is 18-25 kHz, the centrifugation time of a centrifugal machine is 10-60 min, and the centrifugation rotation speed of the centrifugal machine is 2000-4000 r / min. The separation method of the solid phase and liquid phase of the waste drilling fluid is to separate the waste drilling fluid subjected to the centrifugation by the centrifugal machine. The beneficial effects of the method is as the follows that compared with conventionalwaste-drilling-fluid solid-liquid separation methods, such as plate-frame pressure filtration, high-speed centrifugation and the like, the solid-liquid separation method of the waste drilling fluid provided by the invention is carried out by using the ultrasonic wave treatment, the centrifugation of the waste drilling fluid, and the separation of the solid phase and liquid phase; the treatment technology is simple, the operability is high, and the treatment cost is low. The method is especially suitable for harmless treatment and resource utilization of waste drilling fluids in the explorationand development process of petroleum and natural gas.

Owner:CHINA PETROCHEMICAL CORP +3

C/gamma-Fe2O3 composite material recycling method

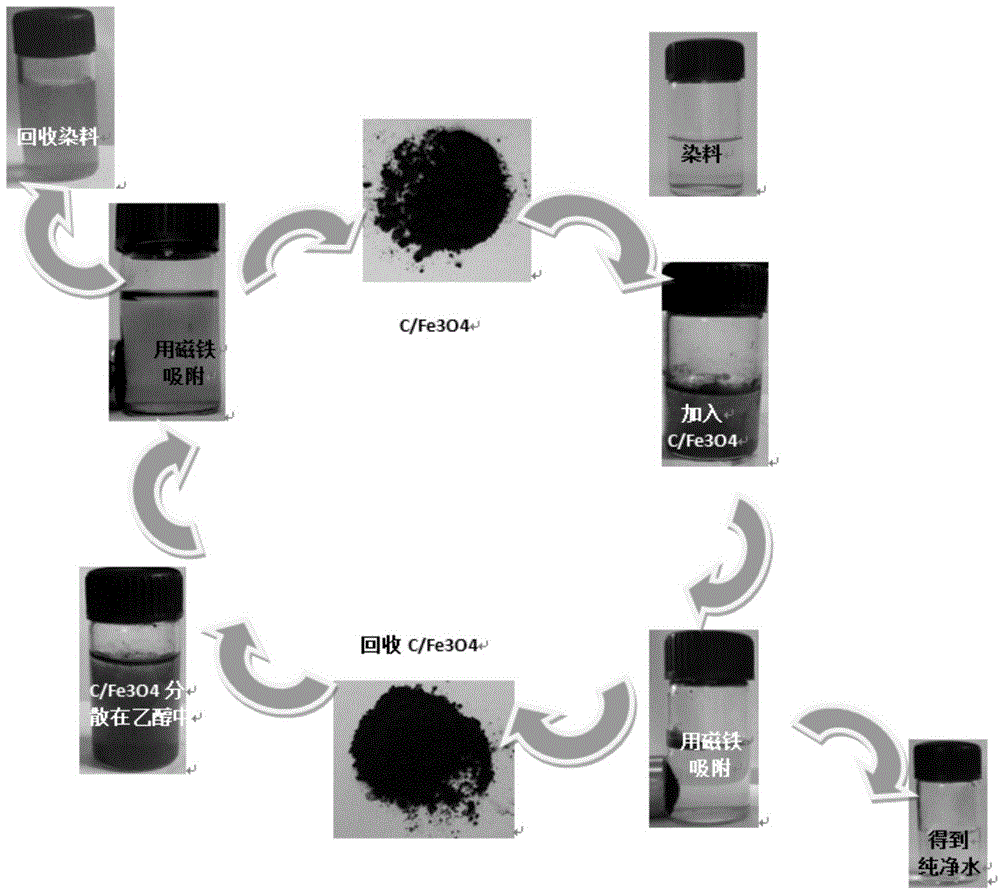

InactiveCN105536754ASolve the problem that is not easy to reproduceSimple processOther chemical processesCombustible gas purificationOrganic solventDesorption

The present invention provides a C / gamma-Fe2O3 composite material recycling method, which comprises: (1) sprinkling a C / gamma-Fe2O3 composite material onto the surface of oil water or dye sewage, and carrying out bubbling stirring to completely adsorb the dye or oil; (2) electrifying an electric magnet, and carrying out magnetic recovery on the C / gamma-Fe2O3; (3) carrying out power-down on the electric magnet, dispersing the recovered C / gamma-Fe2O3 composite material of the absorbed oil or dye in an organic solvent, and carrying out bubbling stirring; and (4) electrifying the electric magnet again, carrying out magnetic adsorption on the desorbed C / gamma-Fe2O3 composite material, sprinkling in an organic solvent again, carrying out desorption, repeatedly performing the steps 3-5 times, recovering the C / gamma-Fe2O3 composite material, and drying so as to be recycled. According to the present invention, the method has characteristics of simple process and easy operation; the characteristics of the material are used to achieve the magnetic oil water separation; and the continuity is strong, the problem that the traditional material is not easily regenerated is well solved, and the resource recycling and re-use is achieved.

Owner:BAOSHAN IRON & STEEL CO LTD

Method for comprehensively extracting active substances from asparagus scraps based on multi-stage membrane separation

InactiveCN102532333AEasy extractionImplement extractionSugar derivativesSugar derivatives preparationUltrafiltrationSeparation technology

The invention relates to a method for comprehensively extracting active substances from asparagus scraps based on multi-stage membrane separation, which comprises the following steps that: the asparagus scraps are used as a raw material, are extracted with hot water of PH = 7-9 to obtain an extract, and then the extract is subjected to sedimentation centrifugation and 100-800-mesh bag filtering; the extract is subjected to an ultrafiltration membrane with interception molecular weight of 5000-15000Da to obtain a concentrated solution and a filtrate, the concentrated solution is precipitated with 75-95% alcohol to obtain an asparagus polysaccharide precipitate, and the asparagus polysaccharide precipitate is separated and dried to obtain asparagus polysaccharide with the content of 50%; the obtained filtrate is concentrated with a nanofiltration membrane with the molecular weight of 100-500Da to obtain a concentrated solution, the pH value of the concentrated solution is adjusted to 3-4, the concentrated solution is precipitated and dried to obtain rutin; and finally, a dialysate is pumped back to an extraction tank to be used as water for extraction. The residues are crushed to be used for feed. The process adopts an advanced membrane separation technology, improves the preparation efficiency of asparagus polysaccharide and rutin, realizes clean production and no waste water and residue emission, turns waste into wealth and realizes comprehensive utilization of resources. The method has the advantages of advanced process, stable product quality, high purity, clear target and easiness in industrial production.

Owner:FUJIAN HUIZE BIOTECH

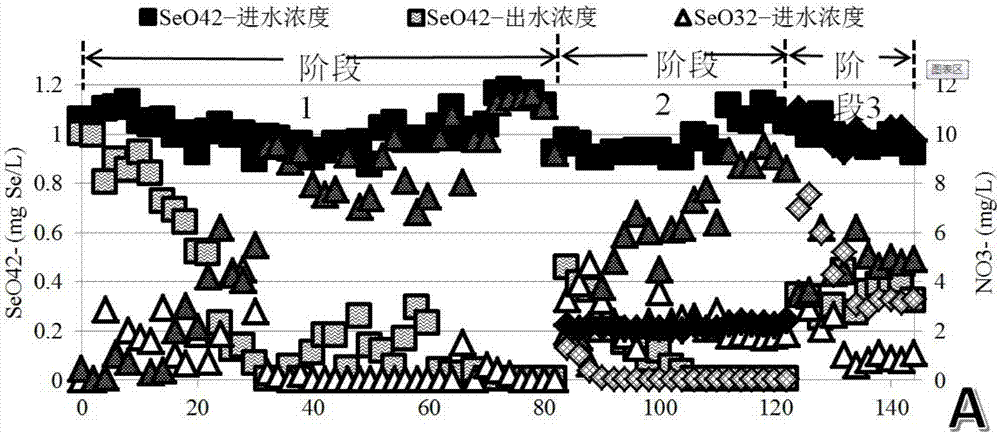

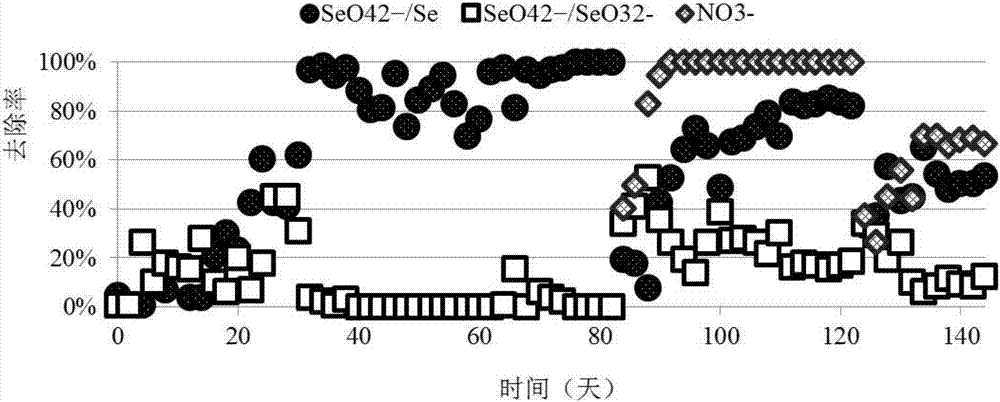

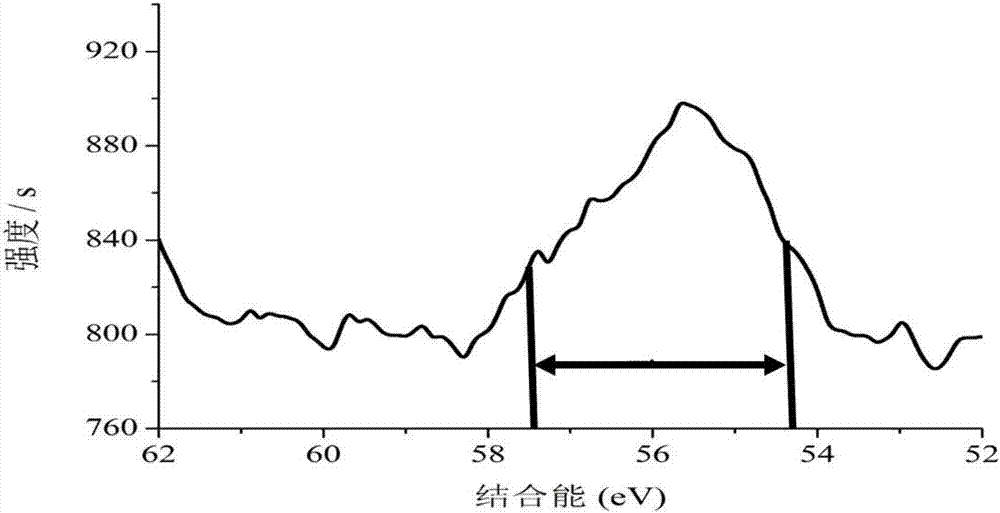

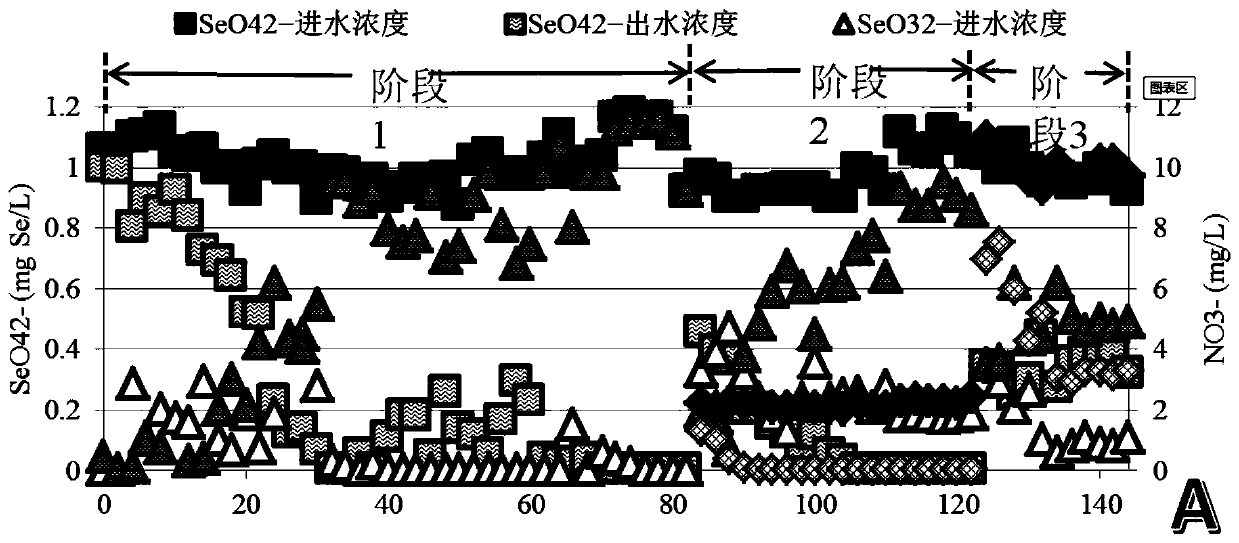

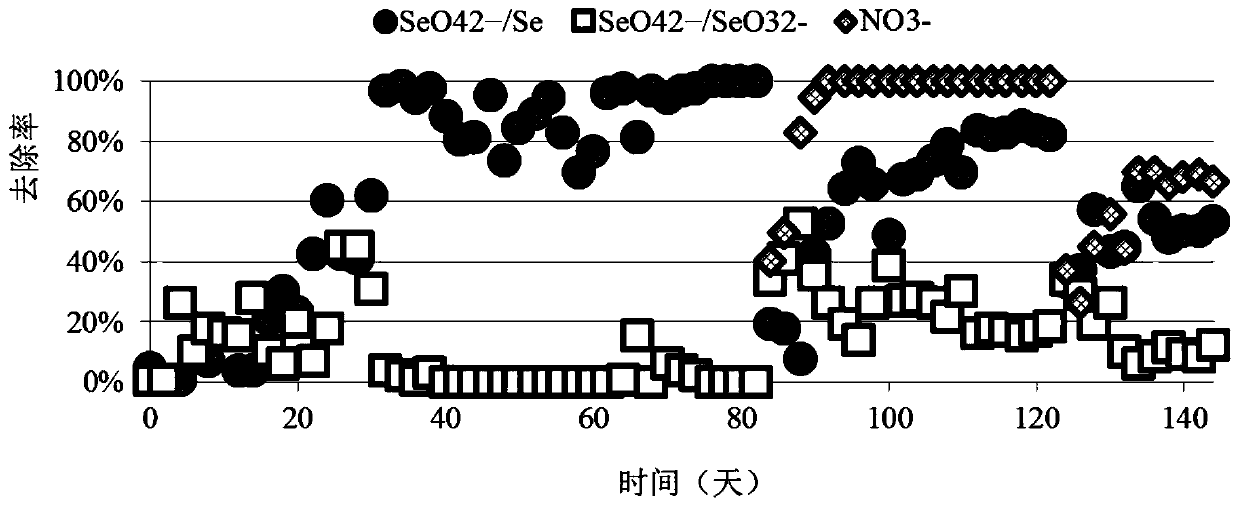

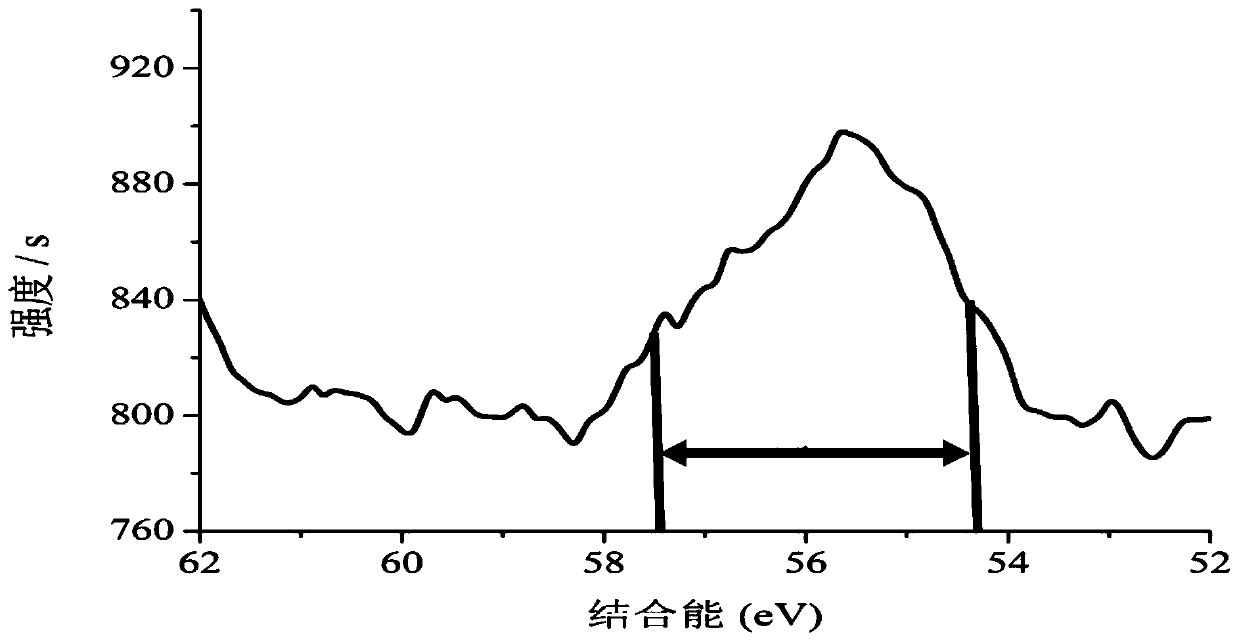

Method for assessing selenate and nitrate reducing ability of methane matrix MBfR

ActiveCN107244734AConfirmed reductionRepair pollutionWaste based fuelTreatment with anaerobic digestion processesSelenateElectron donor

The invention relates to the technical field of bioremediation of oxidation-state pollutants, and aims at providing a method for assessing the selenate and nitrate reducing ability of a methane matrix MBfR. The method comprises the following steps: adding solutes to deionized water to prepare simulated wastewater, and introducing argon to carry out aeration; inoculating a methane matrix membrane bioreactor with a methane anaerobic oxidation coupled perchlorate-reducing community as an inoculation source; feeding the simulated wastewater in a continuous flow manner; keeping the concentration of SeO<4><2-> in the simulated wastewater stable, controlling the concentration of NO<3><-> in three stages, and allowing the reactor to enter a next stage after reaching a stable state. It is confirmed that microbes can drive the reduction of the SeO<4><2-> as a only electron donor for the first time. The methane matrix MBfR can remedy SeO<4><2-> polluted water, and also can realize the resource recycling of nanometer Se<0>.

Owner:ZHEJIANG UNIV

Method using agricultural waste composting to produce flower culture medium

InactiveCN110663506ARealize resource recovery and reusePromote growthGrowth substratesCulture mediaAnthesisAgricultural engineering

The invention relates to a method using agricultural waste composting to produce a flower culture medium. The method is characterized by including the steps of S1, preprocessing agricultural waste; S2, performing composting fermentation; thirdly, preparing the culture medium. The invention further provides a flower culture medium produced by the method. The produced flower culture medium can evidently promote flower growth, can allow flowers to grow robustly and have dark green leaves and large and many flowers bright in color and can prolong the flowering period; the produced culture medium is low in cost, energy-saving, environmentally friendly, sufficient in nutrients and good in breathability and water-retaining performance; agricultural waste recycling can be achieved, waste is turnedinto treasure, energy is saved, and environmental protection is benefited.

Owner:CHANGSHU JIASHENG AGRI SCI & TECH DEV

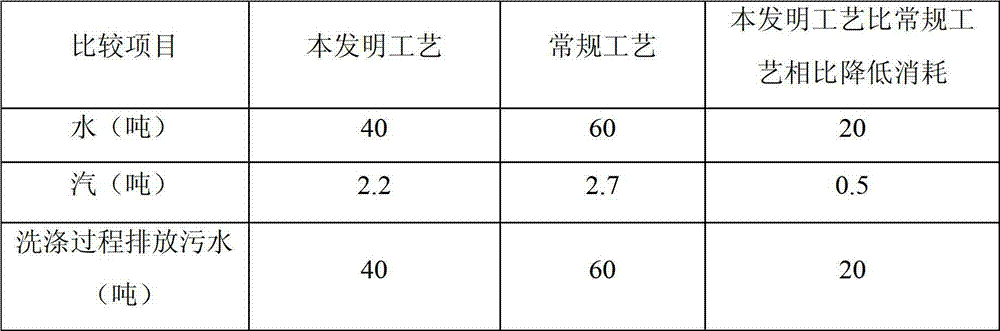

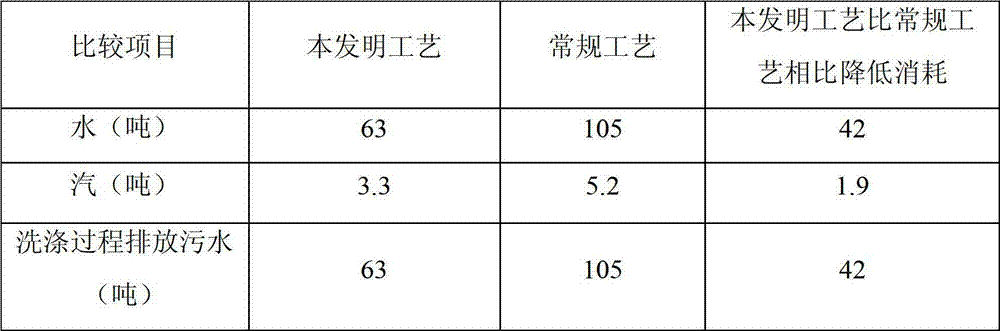

Processing method for removing hydrolyzed reactive dyes on cotton knitted fabric by using solvent water system

InactiveCN102888766AReduced post-processing timeIncrease productivityDry-cleaning apparatus for textilesDyeing processWater dischargeSolvent

The invention relates to a processing method for removing hydrolyzed reactive dyes on a cotton knitted fabric by using a solvent water system. The processing method comprises the steps that: (1) residual dye liquid is removed after the cotton knitted fabric is dyed, then washing and soaping are carried out; (2) a solvent and water are mixed according to the volume ratio of 1:1-1:3 under the condition of room temperature, and the pH value of the mixture is adjusted to form a solvent water system; and (3) the pretreated dyed cotton knitted fabric is processed for two times by using the solvent water system. According to the method, the dyed cotton knitted fabric is processed by the low-temperature solvent water system for two times rather than one-time high-temperature washing and two-time room-temperature washing in the conventional washing process, the after treatment time is shortened, the production efficiency is improved, and the production cost is reduced; the recovery and recycling of sources is achieved through a solvent recovery system, the production cost is saved, and the environment pollution is reduced; and the after treatment water consumption is greatly saved due to the recovery and repeated use of the solvent, the waste water discharge is reduced, the energy consumption is reduced, and remarkable economic benefit and social benefit are achieved.

Owner:DONGHUA UNIV +1

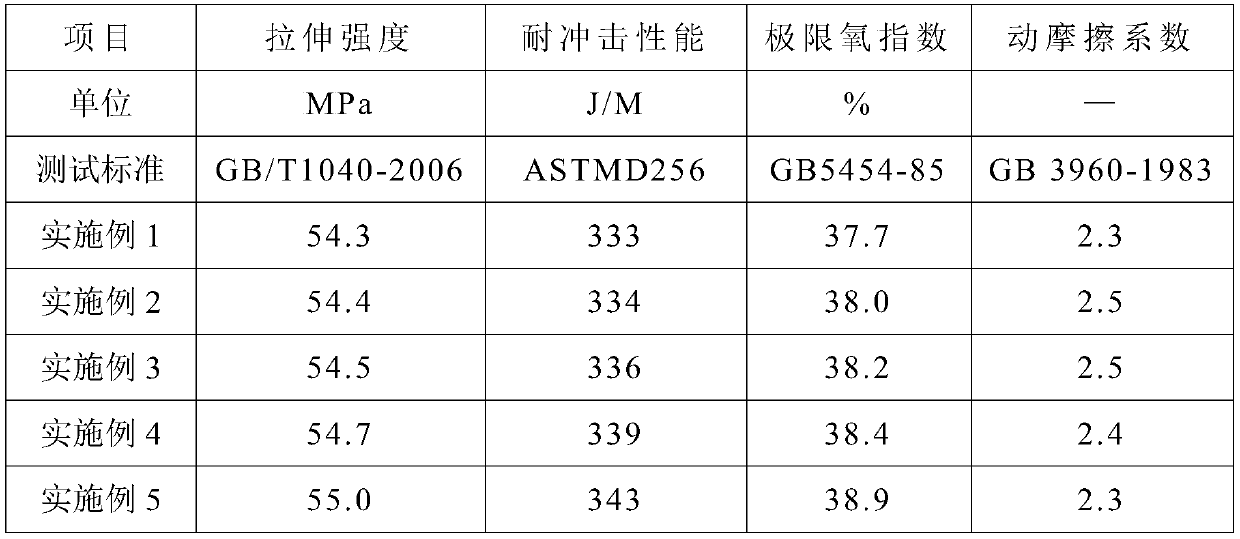

Wear-resistant high-strength plastic particles produced from waste plastic

InactiveCN110615993ARealize resource recovery and reuseImprove pass ratePlastic recyclingWeather resistanceWear resistant

The invention discloses a method for producing wear-resistant high-strength plastic particles from waste plastic, which is characterized by comprising the following steps: S1, pretreatment of the waste plastic, S2, preparation of poly(allyl 3,5-diamino-1H-pyrazole-4-carboxylate 2,3,5,6-tetrafluoroterephthalic acid) amide, and S3, molding of the plastic particles. The invention also discloses the plastic particles produced by the method for producing the wear-resistant high-strength plastic particles by using the waste plastic. The plastic particles disclosed by the invention can realize resource recycling of waste plastic in an environment-friendly, safe, efficient and rapid manner, can change waste into valuables, is high in strength, excellent in wear resistance and good in weather resistance and performance stability, and has relatively high economic value, social value and ecological value.

Owner:界首市圣通无纺布有限公司

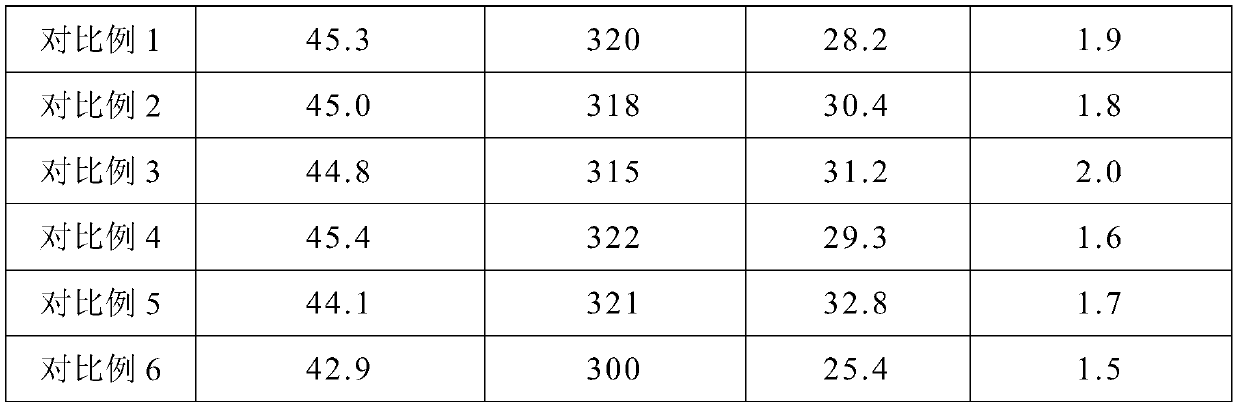

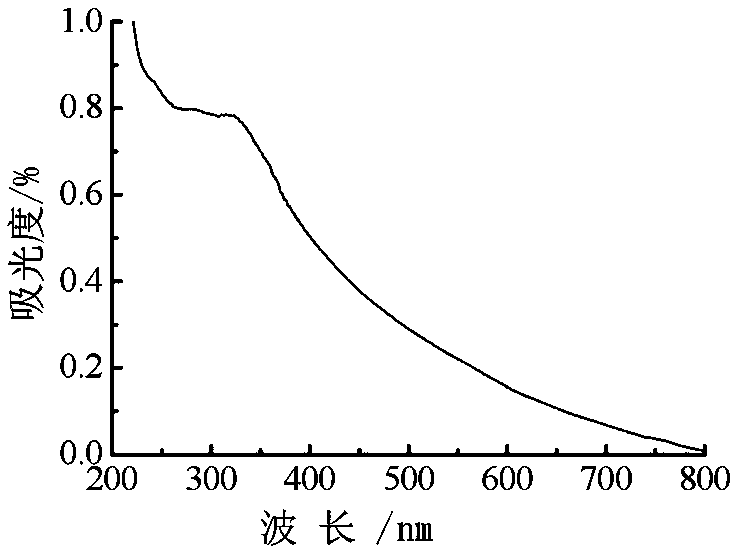

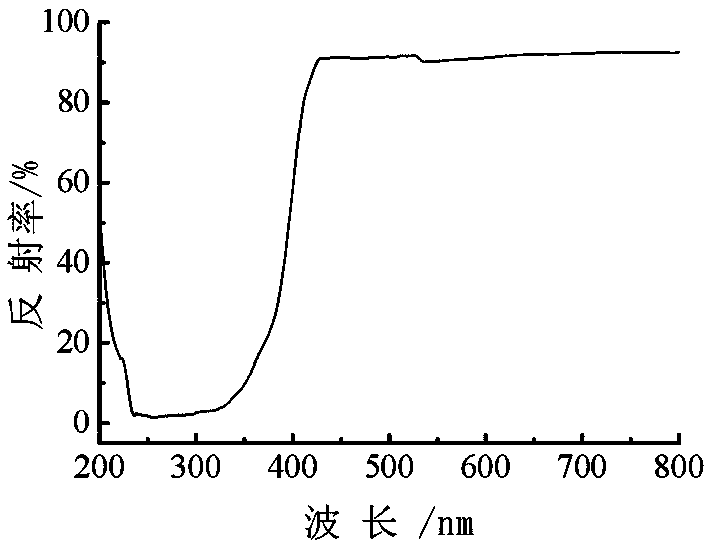

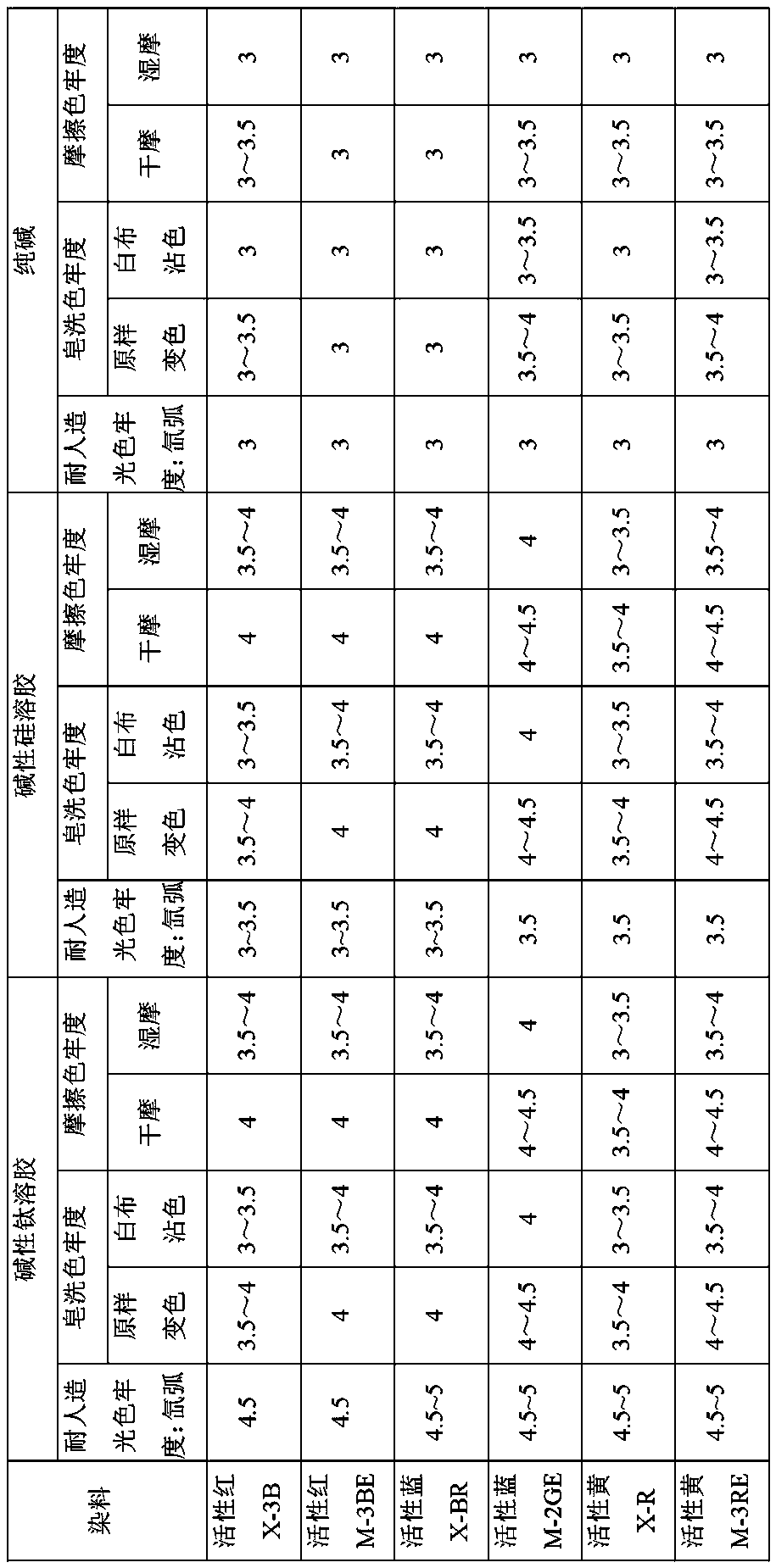

Basic titanium sol dye-fixing agent as well as preparation method and application thereof

The invention provides a basic titanium sol dye-fixing agent. The basic titanium sol dye-fixing agent is prepared through sol-gel reaction on butyl titanate, water, alcohol, a catalyst and a silane coupling agent serving as raw materials according to a molar ratio of (1 to 3) to (8 to 16) to (18 to 25) to (2.0 to 3.5) to (0.001 to 0.01). The invention also provides a preparation method of the basic titanium sol dye-fixing agent. The basic titanium sol dye-fixing agent and the preparation method of the basic titanium sol dye-fixing agent disclosed by the invention have the advantages that the colour fastness to light of woods can be obviously improved.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Method for preparing high-strength and high-toughness double-wall corrugated water discharge pipe material by using waste beverage bottles

InactiveCN110628161AImproves Strength and ToughnessFast recyclingPlastic recyclingTubular articlesTemperature resistanceWeather resistance

The invention discloses a method for preparing a high-strength and high-toughness double-wall corrugated water discharge pipe material by using waste beverage bottles. The method comprises: S1, pretreatment of waste beverage bottles; S2, chain extension of the waste beverage bottles; and S3, molding of water discharge pipe material. The invention further discloses the high-strength and high-toughness double-wall corrugated water discharge pipe material prepared according to the method. According to the invention, with the method, the resource recycling of waste beverage bottles can be efficiently and rapidly achieved, waste can be turned into wealth, the double-wall corrugated water discharge pipe with characteristics of high strength, high toughness, good weather resistance, good flame retardance, good high-temperature resistance and long service life can be manufactured, and high economic value, social value and ecological value are achieved.

Owner:安徽超星新材料科技有限公司

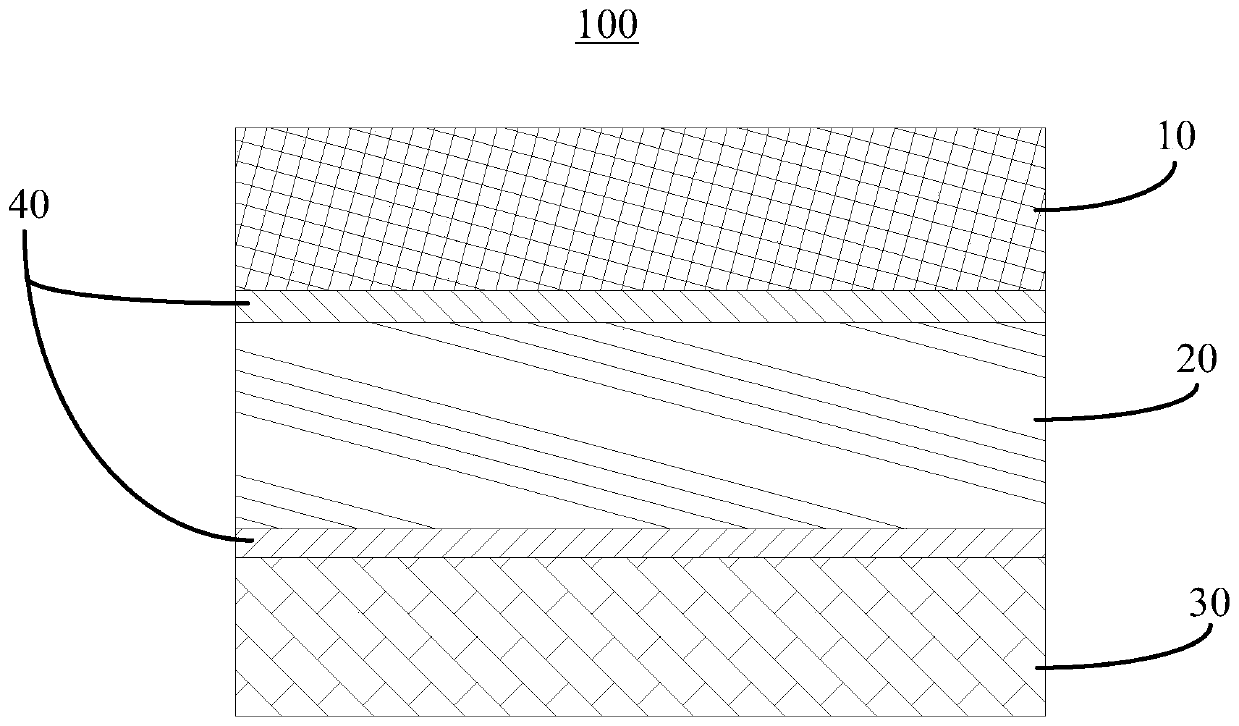

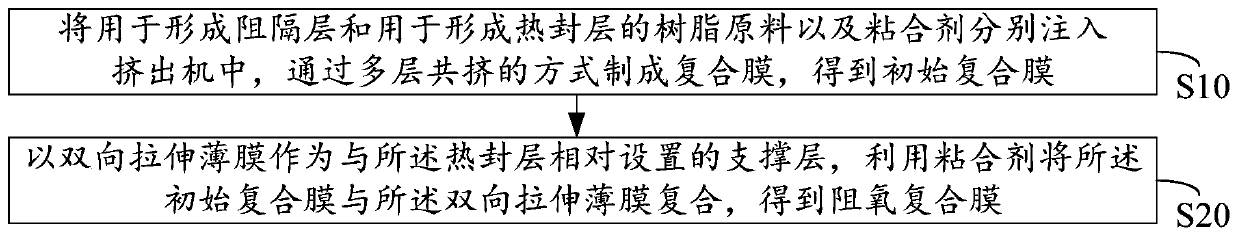

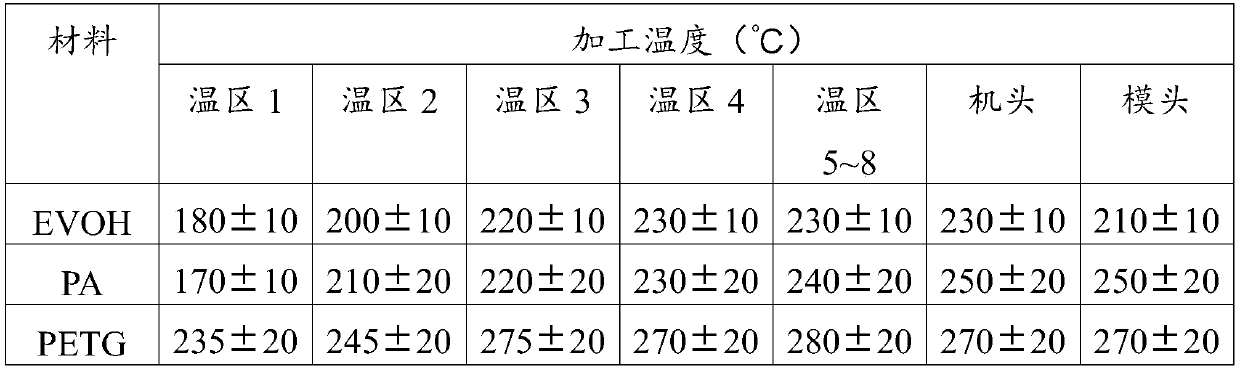

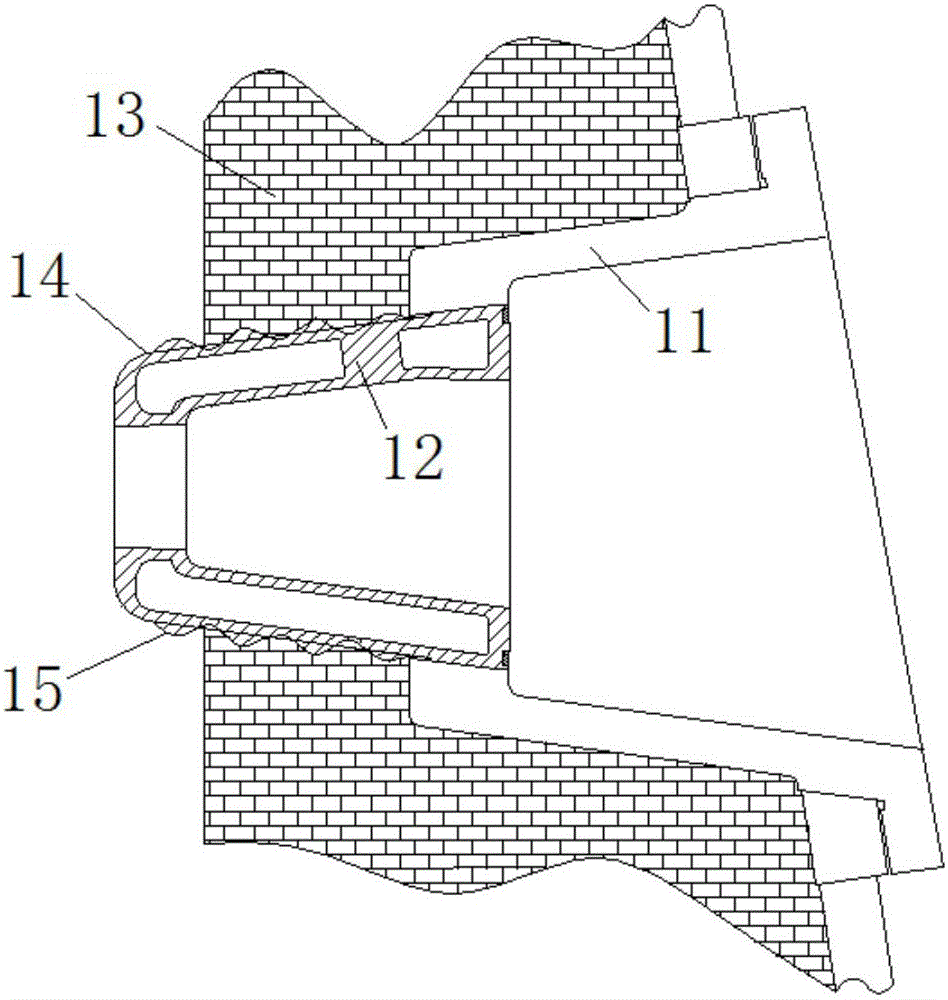

Oxygen blocked composite film and preparation method thereof and packaging box

InactiveCN110092088AGood barrier propertiesRealize resource recovery and reuseFlexible coversWrappersComposite materialBlock layer

The invention discloses an oxygen blocked composite film, a preparation method thereof and a packaging box. The oxygen blocked composite film comprises a heat-sealing layer, a blocked layer and a supporting layer which are stacked in sequence, wherein the heat-sealing layer comprises a thin film layer formed by PETG; the blocked layer comprises at least one first blocked thin film layer formed byEVOH and / or at least one second blocked thin film layer formed by PA; the supporting layer comprises a biaxially oriented thin film; and the fusing co-extrusion compounding is performed between the heat-sealing layer and the blocked layer and between the blocked layer and the supporting layer through bonding layers. When the oxygen blocked composite film provided by the invention is used as a cover film of a PET packaging box body, the packaging can be realized without additionally adding a thin film layer for heat sealing; after the oxygen blocked composite film is used for packaging the PETpackaging box, the oxygen blocked composite film can be completely separated from the packaging box body, and thus, the resource recycling of the PET packaging box is realized.

Owner:武汉莱宝新材料技术有限公司

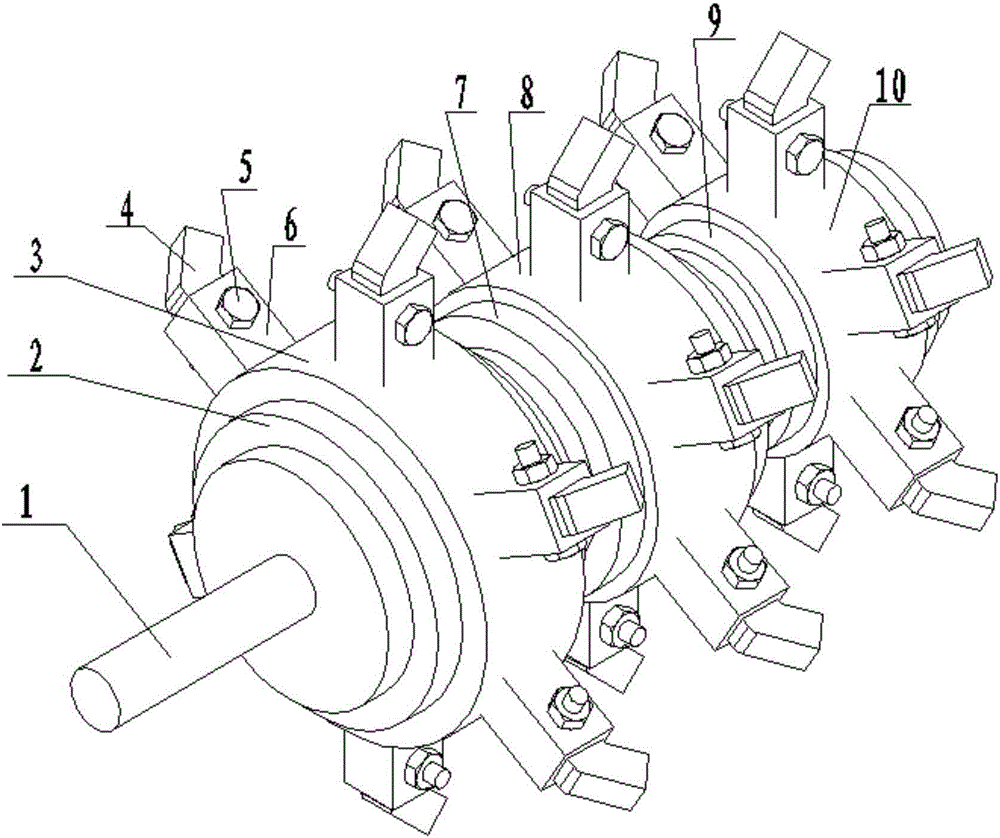

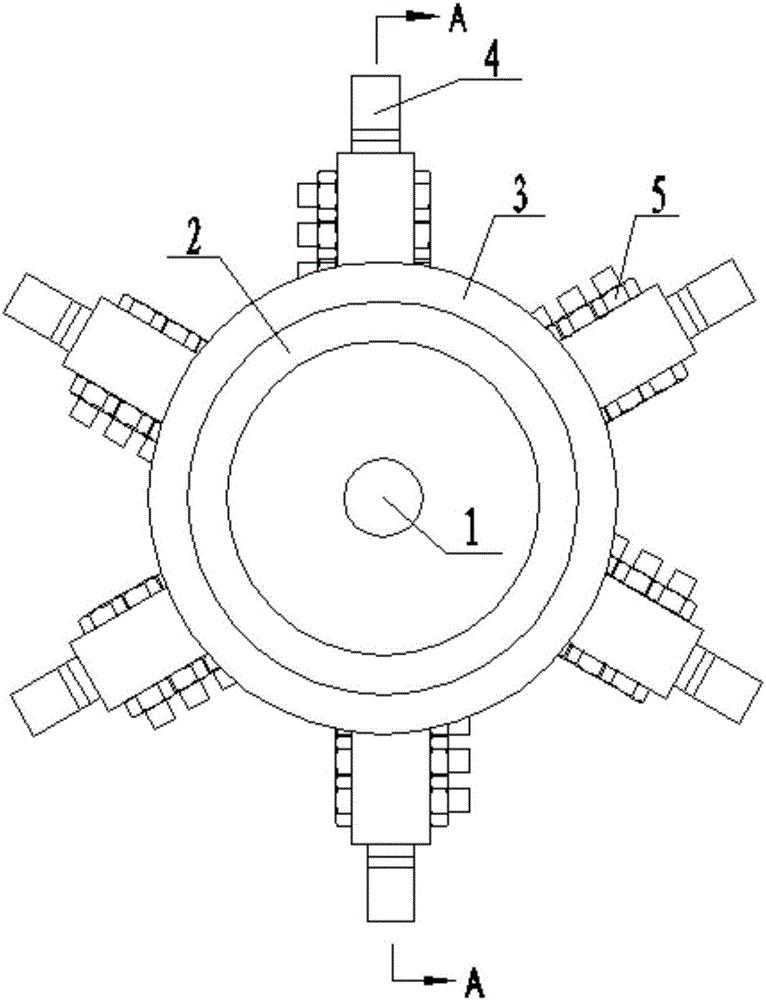

Combined type tool for cutting tuyere second jacket of blast furnace

The invention discloses a combined type tool for cutting a tuyere second jacket of a blast furnace. The tool comprises a rotating shaft. Multiple annular tool bodies are arranged on the rotating shaft in a sleeving manner in the axial direction. The outer diameters of the annular tool bodies distributed on the rotating shaft in the axial direction are gradually reduced. A tool cutting face is formed when outermost cutting points of the multiple annular tool bodies conduct rotary cutting, the annular tool bodies can be moved and adjusted in the axial direction, and therefore the included angle between the tool cutting face and the horizontal plane is adjusted. The requirement for cutting different sizes of tuyere second jackets is met, dense smoke and dust cannot be generated in the tuyere second jacket cutting process, resource recycling of tuyere second jacket copper materials can be achieved, and building of energy-saving and environment-friendly steel enterprises is facilitated.

Owner:武汉钢铁有限公司

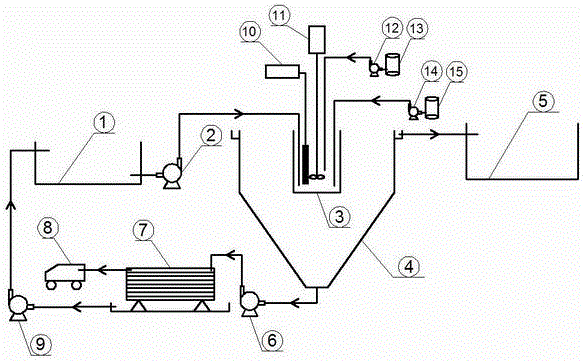

Ammonia nitrogen recovery system for hair product wastewater and operating method of system

InactiveCN105858843AGood removal effectSmall footprintSludge treatment by de-watering/drying/thickeningWater/sewage treatment by heatingHigh concentrationChemical reaction

The invention discloses an ammonia nitrogen recovery system for hair product wastewater and an operating method thereof, and belongs to the technical field of high-concentration ammonia nitrogen wastewater treatment and ammonia nitrogen recovery. The present invention integrates the heating reaction tank and the reaction sedimentation tank into one, by adding the precipitating agent MgCl to the heating reaction tank 2 solution and Na 2 HPO 4 solution to complete the chemical reaction, the reaction sedimentation tank is designed as an overflow weir, and the reacted water in the heated reaction tank enters the reaction sedimentation tank through overflow, and the generated MgNH 4 PO 4 ·6H 2 O is precipitated in the reaction sedimentation tank, and the clarified sewage overflows from the surrounding of the reaction sedimentation tank. The sediment in the sludge hopper of the reaction sedimentation tank is treated by a plate and frame filter press and transported outside for further stacking treatment as fertilizer. The invention has compact equipment, small occupied area, easy realization of automatic control, simple operation management, stable operation, better removal of ammonia nitrogen and realization of resource recovery and reuse.

Owner:HENAN NORMAL UNIV

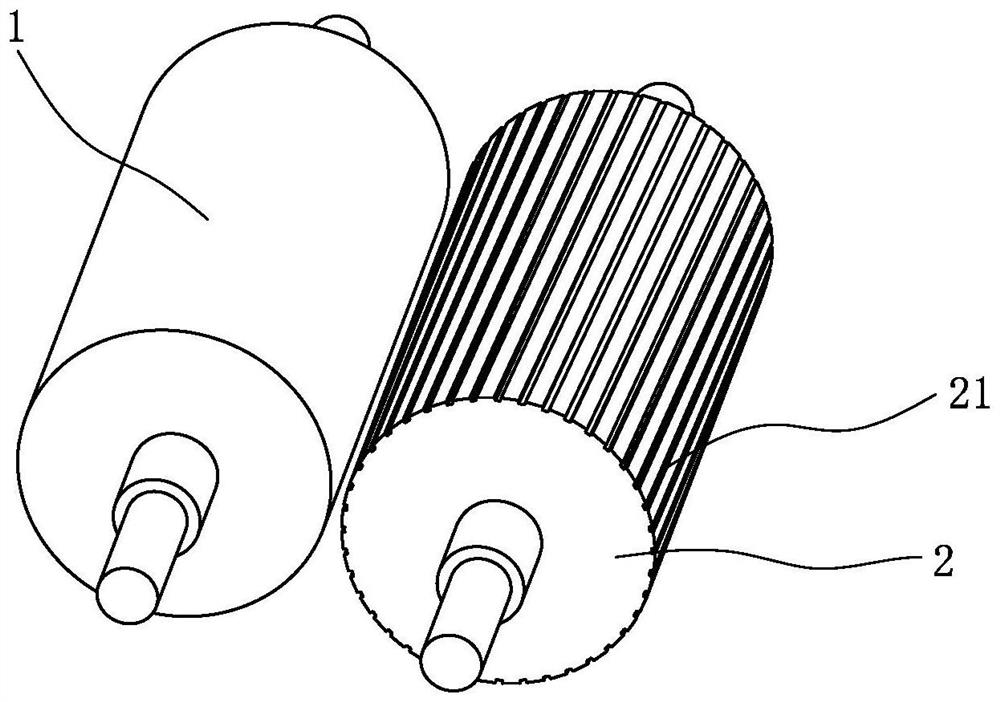

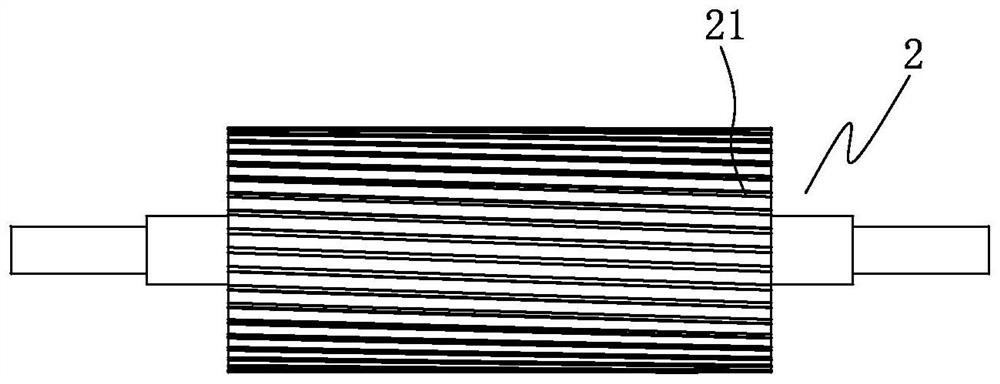

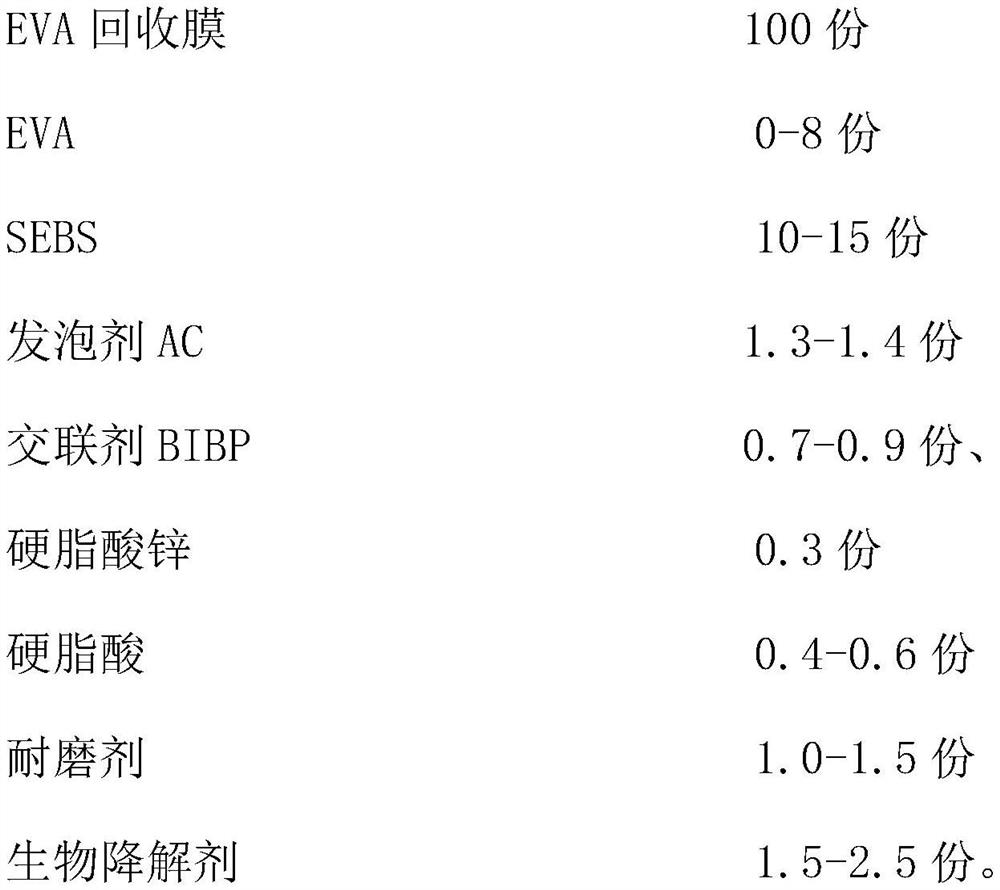

Environment-friendly foaming material based on EVA waste material and treatment method of EVA waste material

PendingCN114479255ARealize resource recovery and reuseMeet environmental protection requirementsPlastic recyclingResource recoveryCeiling temperature

The invention discloses an environment-friendly foaming material based on EVA waste materials and a treatment method of the EVA waste materials. The treatment method comprises the following steps: step 1, crushing waste materials such as waste EVA shoe soles, waste EVA sheets, waste EVA leftover materials and the like to obtain strip-shaped crushed materials; 2, the strip-shaped crushed materials obtained in the step 1, sarin resin and PMP are put into an internal mixer according to the weight ratio of 85: (4-10): (4-8), the internal mixing temperature is gradually increased, the highest temperature is 150 DEG C, the internal mixing time is 18-25 min, and blocky internal mixing materials are obtained; step 3, treating the blocky internal mixing material after internal mixing through a screw extruder and an open mill to obtain an EVA recovery film; by limiting the specific treatment mode of the EVA waste materials, resource recycling of EVA shoe sole material heads, defective products, waste products and leftover materials is achieved, the environmental problem caused by white pollution is relieved, the adding proportion of the treated EVA waste materials in shoe sole preparation can be increased to 70% or above, resource waste is greatly reduced, and the utilization rate of the waste materials is increased.

Owner:MAOTAI FUJIAN SOLES CO LTD +1

Process for purifying and resource recovery using from waste water of producing H cide

InactiveCN100415654CAchieve separationAchieve recyclingWater/sewage treatment by sorptionAqueous sodium hydroxideResource recovery

A method for cleaning and reclaiming the sewage generated by preparing H acid includes such steps as filtering, adsorbing by resin column for separating H acid and T acid frmo the saturated solution of sodium sulfate, using the saturated solution to flush the fitlered cake of H acid and T acid, eluting the resin column by aqueous solution of sodium hydroxide, returning the high-concetnration sodium salt solution back to alkali fusing step, and preparing the aqueous solution of sodium hydroxide from the low-concentration desorptive liquid for desorptive step.

Owner:NANJING UNIV +1

Magnetic carbon-based catalyst and method for preparing biodiesel by using same

ActiveCN113926459AHigh catalytic activityActive substance distributionFatty acid esterificationBiofuelsSodium methoxideBiodiesel

The invention discloses a magnetic carbon-based catalyst which is prepared by the following steps: grinding electric furnace dust by using a ball mill, and carrying out drying at 75-105 DEG C to obtain pretreated electric furnace dust; taking the pretreated electric furnace dust, adding concentrated hydrochloric acid, adding deionized water and a carbon source after reaction, conducting stirring, filtering and washing until the pH value of the solution is neutral, and carrying out drying; calcining a dried sample at 600-800 DEG C for 2 hours or more to obtain a magnetic carbon carrier; and mixing the obtained magnetic carbon carrier and sodium methoxide, adding deionized water, conducting mixing at a constant temperature, carrying out magnetic stirring, performing drying, heating the dried sample to 600-700 DEG C at a heating rate of 5-7 DEG C / min in an inert gas, keeping the sample at the temperature for 2 hours or more, and carrying out cooling to obtain the magnetic carbon-based catalyst. The catalyst has a good catalytic effect, the yield of biodiesel is greater than 98%, and the yield of the catalyst after returning is greater than 90%. And moreover, the recycling capability of the catalyst is better, and the yield of the biodiesel can reach 80% or above after seven times of reactions.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

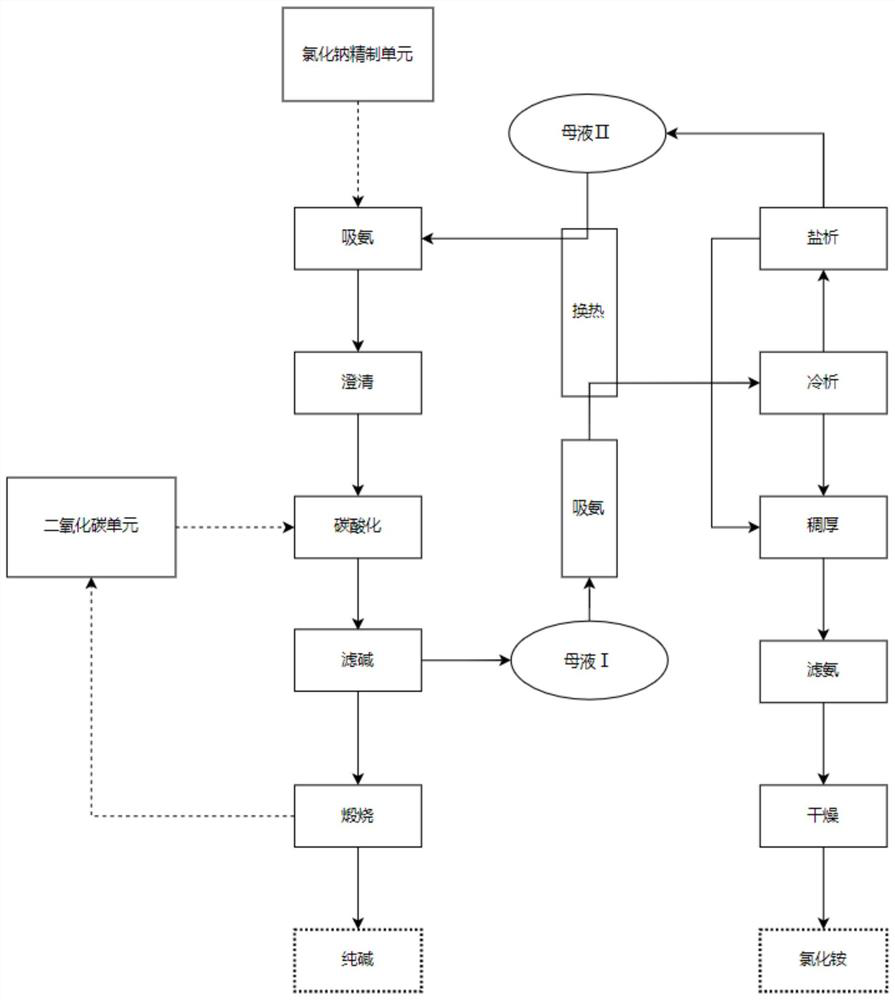

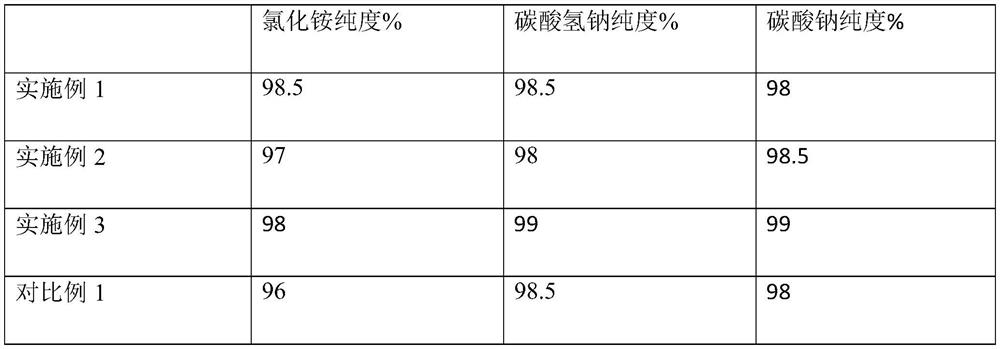

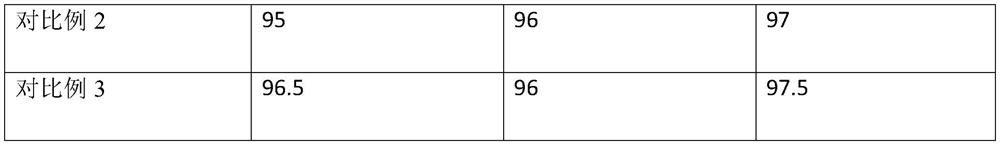

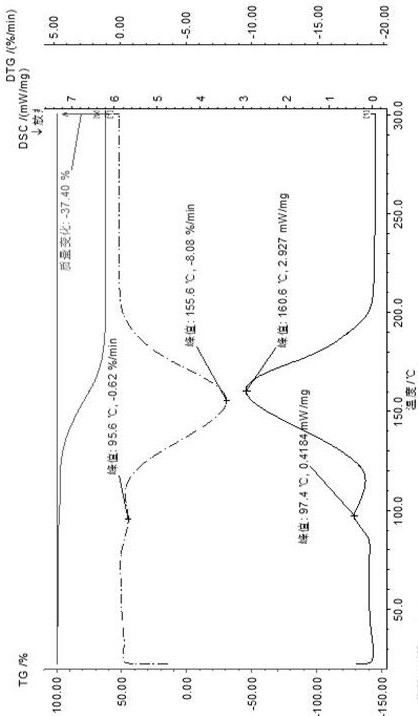

Waste salt resourceful treatment system and treatment method thereof

PendingCN114162837AHarmlessRealize resource recovery and reuseProductsCarbon compoundsCarbon dioxide productionExhaust fumes

The invention discloses a waste salt resourceful treatment system and a waste salt resourceful treatment method. Comprising a sodium chloride refining unit for refining and recovering sodium chloride in waste salt, a carbon dioxide unit for capturing and purifying industrial carbon dioxide waste gas, and industrial baking soda produced by using refined sodium chloride produced by the sodium chloride refining unit and carbon dioxide produced by the carbon dioxide unit, and a resource utilization unit of sodium carbonate and ammonium chloride. According to the invention, the waste salt and the industrial carbon dioxide tail gas are used as raw materials to obtain high-purity industrial-grade baking soda, soda ash, ammonium chloride and other products, so that resource recycling of the waste salt and the industrial carbon dioxide is realized, and the energy-saving and emission-reducing effects are remarkable. Compared with the prior art, the product prepared by the method is higher in purity and better in quality.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

Foaming agent based on cyclohexanone by-product spent lye as well as preparation method and application of foaming agent

The invention provides a foaming agent as well as a preparation method and an application method thereof. The foaming agent provided by the invention is prepared from a raw material: waste alkali liquor of a cyclohexane oxidation to cyclohexanone process. According to the preparation method of the foaming agent, the cyclohexanone waste alkali liquor can be effectively recycled, resource reutilization is achieved, the prepared foaming agent has a good foaming effect, and the closed-cell rate is larger than 95%.

Owner:SINOPEC NANJING RES INST OF CHEM IND CO LTD +2

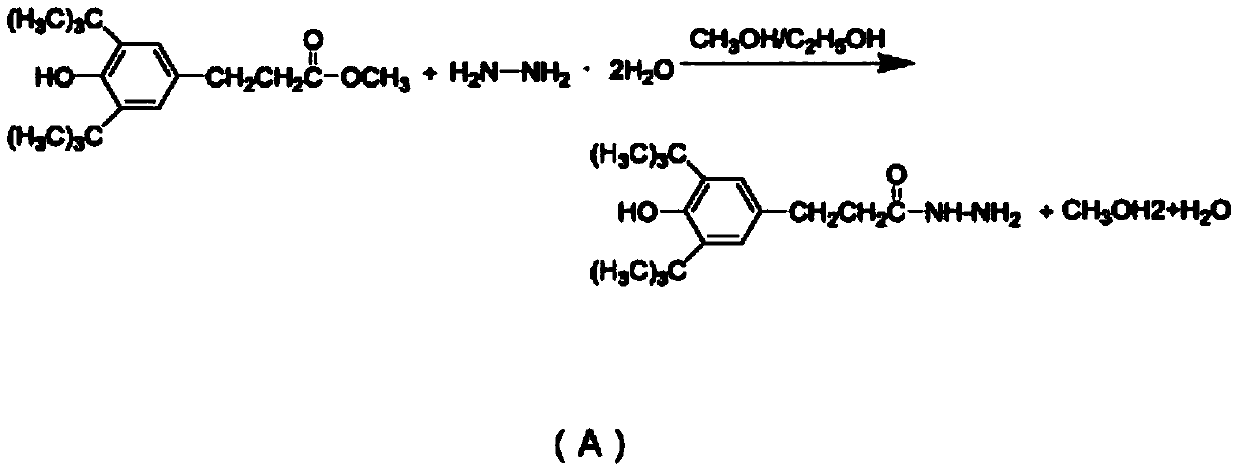

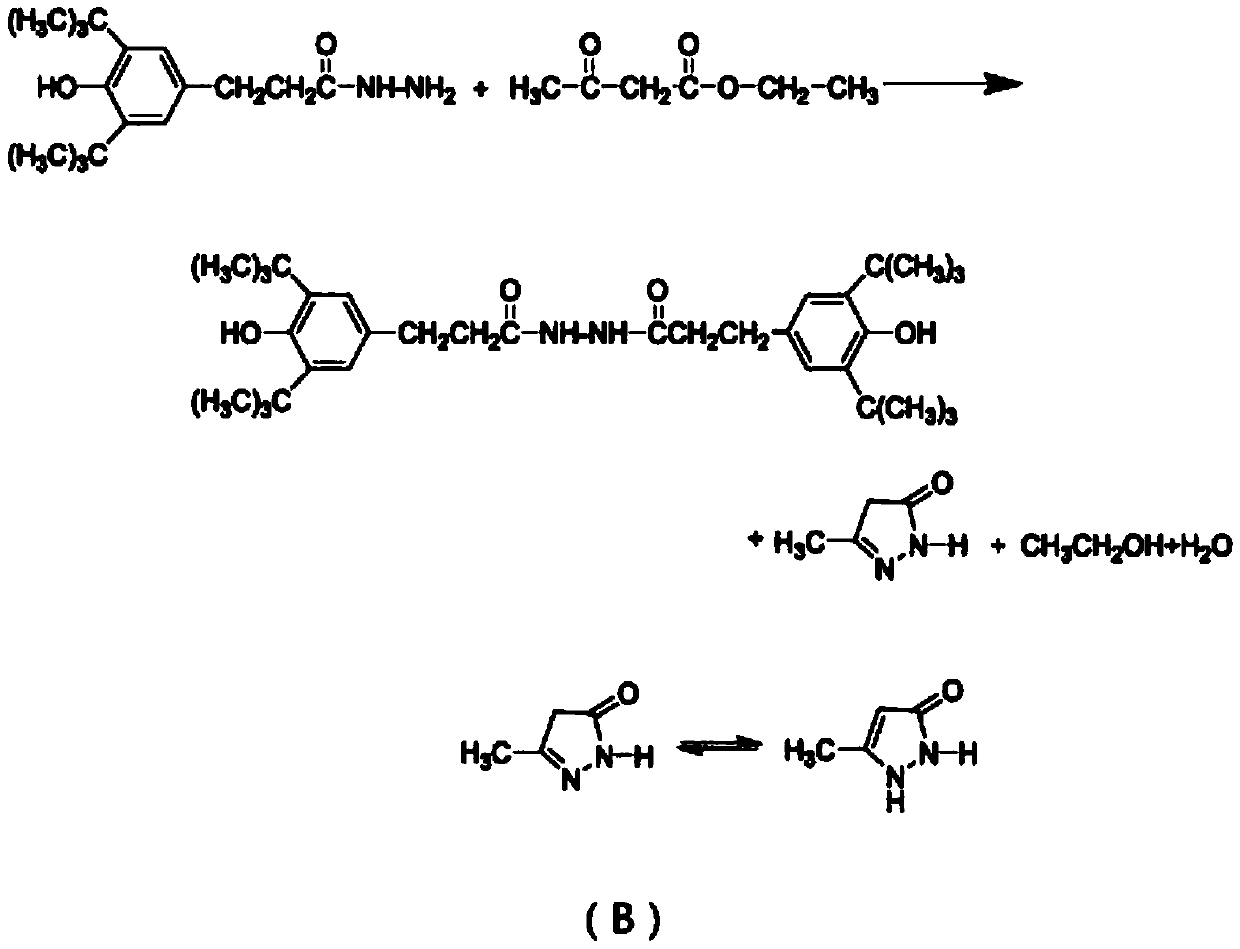

Method of recovering antioxidant 1024 intermediate

The invention discloses a method of recovering an antioxidant 1024 intermediate, and relates to the technical field of organic chemistry. The method includes the following steps: pre-treatment on antioxidant 1024 reaction waste liquid, first solid-liquid separation, first vacuum distillation, secondary solid-liquid separation, secondary vacuum distillation, crystallization, collection and packaging. When the method disclosed by the invention is used to fully recover and utilize by-products in the antioxidant 1024 reaction waste liquid, toxin of products is reduced, the production is energy-conserving and environmentally friendly, and pollution to the environment is avoided. The technique is easy and convenient for operation, separation and extraction, and storage. Secondary pollution is effectively avoided. The antioxidant 1024 intermediate is fully recovered. Resourceful utilization is realized. Raw material cost of the antioxidant 1024 is greatly reduced. Large-scale industrialized production of the antioxidant 1024 is possible.

Owner:JIANGSU JIYI NEW MATERIAL CO LTD

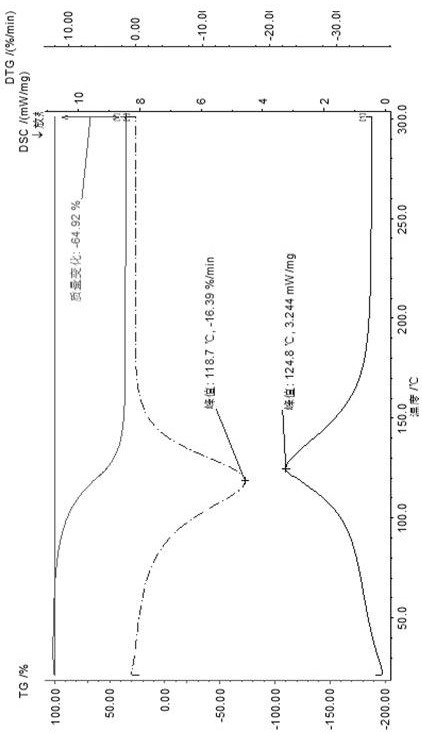

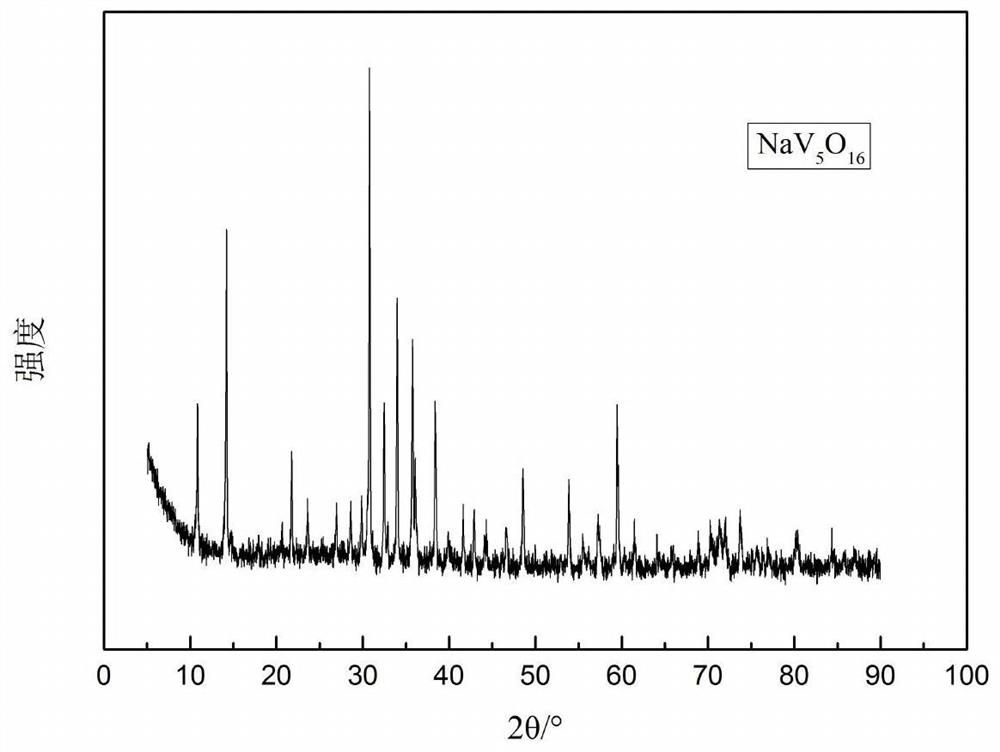

Method for producing nav6o15 sodium-ion battery electrode material by using spent vanadium battery electrolyte

ActiveCN110729474BHigh purityImprove uniformityFuel cells disposal/recyclingCell electrodesElectrolytic agentPhysical chemistry

The invention discloses a method for preparing NaV by utilizing the failed vanadium battery electrolyte 6 O 15 The method for the electrode material of sodium ion battery belongs to the technical field of sodium ion battery, and comprises the following steps: (1) taking the vanadium battery electrolyte that has failed, and feeding it into the positive electrode of the vanadium battery for charging and preoxidation to obtain an electrolyte of pentavalent vanadium ions; (1) 2) adjusting the pH of the pentavalent electrolyte ≤ 0; (3) adding a surfactant to the electrolyte obtained in step (2), and after the reaction is complete at 100-120° C., cooling, washing and drying to obtain NaV 6 O 15 . In the invention, the failed vanadium battery electrolyte is used as the raw material to realize resource recovery and reuse; and in the preparation of NaV 6 O 15 No additional preparation precursor is required in the process, the process method is simple, the cost is low, and it is easy to popularize and apply; at the same time, the NaV prepared by the present invention 6 O 15 With high purity, good uniformity and small particle size, it can be used as a positive electrode material for sodium ion batteries with excellent performance.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD

A kind of production process of passenger car air duct with polyurethane scrap mold making and three-dimensional core material structure polyurethane foam

ActiveCN108724545BGood insulation propertiesImprove toughnessDomestic articlesGlass fiberManufacturing technology

The invention discloses a passenger car air channel production technology adopting three-dimensional core material structure polyurethane foaming. By means of the method of additionally arranging a heat preserving layer filled through polyurethane leftover materials, compared with an existing foaming mould manufacturing technology, the heat preserving performance of the mould can be better, glassfiber has excellent toughness and strength, by means of reasonable preparation, the service life of the mould can be prolonged, resin is added into the leftover materials, the mould can have coagulability, and forming of the mould can be promoted. The polyurethane glass fiber enhanced hard foaming leftover materials are used as mould filler, recycling and reusing of resources can be achieved, andthe cost investment of the mould is reduced. By means of the form of adding the heat preserving layer for the mould, polyurethane materials keep the constant temperature in the transferring and foaming process, and the good mobility is achieved. Three-dimensional core materials are used, the use quantity of the polyurethane materials can be reduced, weight reduction of products is achieved, and the production period is shortened.

Owner:GUIZHOU HUAYUN AUTOMOBILE DECORATING PART MFG CO LTD

Method for assessing the ability of methane substrate MBFR to reduce selenate and nitrate

ActiveCN107244734BConfirmed reductionRepair pollutionWaste based fuelTreatment with anaerobic digestion processesElectron donorPerchlorate

The invention relates to the technical field of bioremediation of oxidation-state pollutants, and aims at providing a method for assessing the selenate and nitrate reducing ability of a methane matrix MBfR. The method comprises the following steps: adding solutes to deionized water to prepare simulated wastewater, and introducing argon to carry out aeration; inoculating a methane matrix membrane bioreactor with a methane anaerobic oxidation coupled perchlorate-reducing community as an inoculation source; feeding the simulated wastewater in a continuous flow manner; keeping the concentration of SeO<4><2-> in the simulated wastewater stable, controlling the concentration of NO<3><-> in three stages, and allowing the reactor to enter a next stage after reaching a stable state. It is confirmed that microbes can drive the reduction of the SeO<4><2-> as a only electron donor for the first time. The methane matrix MBfR can remedy SeO<4><2-> polluted water, and also can realize the resource recycling of nanometer Se<0>.

Owner:ZHEJIANG UNIV

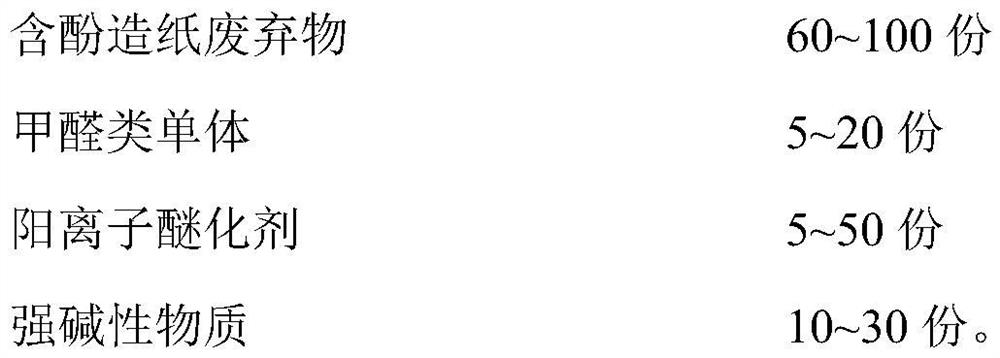

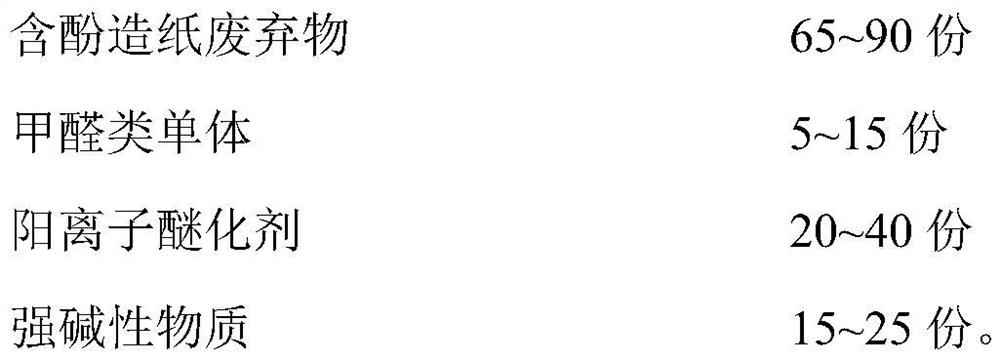

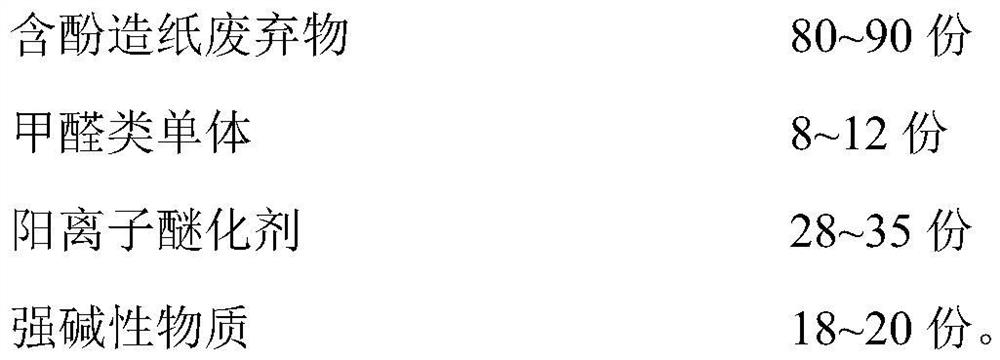

A new type of interlayer adhesive and preparation method and its application in interlayer spraying in papermaking

ActiveCN109680537BEasy to operateHigh bonding strengthAldehyde/ketone condensation polymer adhesivesPaper-making machinesPolymer scienceCarton

The invention discloses a novel interlayer binding glue, a preparation method and its application in spraying between layers of papermaking. The preparation method of the novel interlayer adhesive comprises the steps of: (1) reacting a mixed aqueous solution containing phenolic papermaking waste, formaldehyde monomers and strong alkaline substances at 65° C. to 85° C. for 60 to 300 minutes; ( 2) Then add a cationic etherification agent to the reaction product of step (1), react at 70-90°C for 120-300 minutes, cool and filter to prepare a new type of interlayer adhesive. The novel interlayer bonding glue prepared by the method of the present invention is applied to the production process of bobbin paper, cardboard paper, recycled kraft card and other paper types, which can partially or completely replace the interlayer spray starch, and can effectively improve the production process. Bonding strength between paper layers, ring compressive strength, folding strength, bursting strength and other strength indicators, and its raw materials are widely available, and the price is affordable; it can effectively reduce papermaking waste emissions, reduce pollution, and be beneficial to environmental protection; therefore, the development prospect is very promising.

Owner:JINING MING SHENG NEW MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com