System for automatically recycling acetic acid from ceramic leaching liquid waste

An automatic recovery, acetic acid technology, applied in the separation/purification of carboxylic acid compounds, organic chemistry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

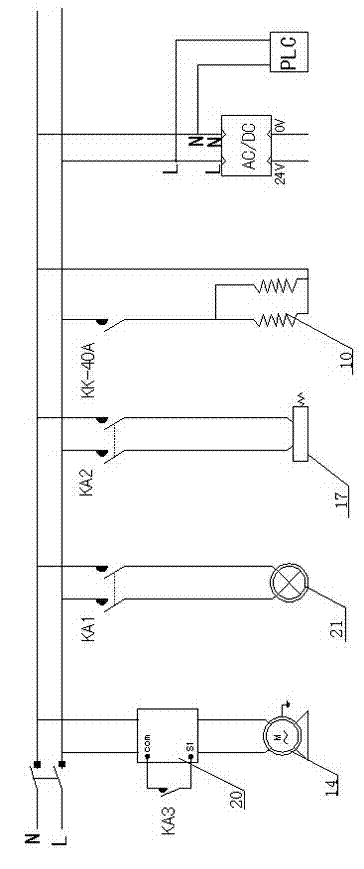

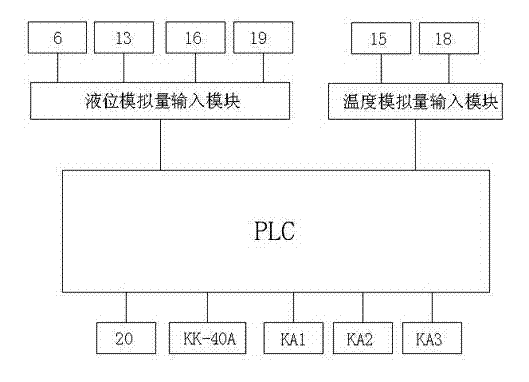

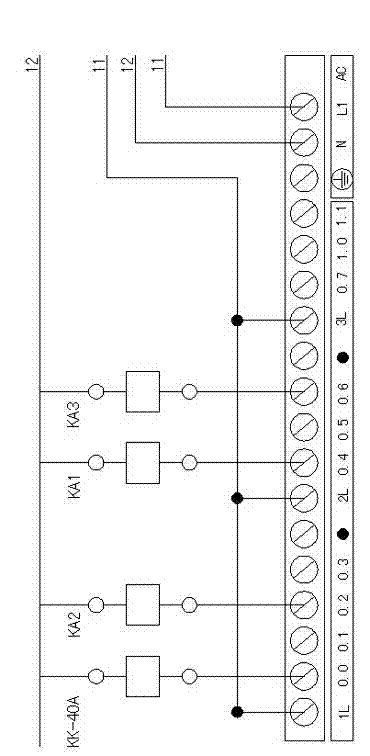

[0032] The present invention will be further described below with reference to the accompanying drawings.

[0033] This embodiment discloses a system for automatically recovering acetic acid from ceramic leaching waste liquid.

[0034] The system is divided into storage heat dissipation device, power heating device, cooling device, collection device, funnel communicator and control device, etc., and is implemented by selecting manual mode or automatic mode through the operation control panel.

[0035] For the structure of the system, see Figure 1-4 ,

[0036] See figure 1 , The storage heat dissipation device is composed of a liquid storage tank 1 and a communication valve 17. The liquid storage tank 1 is a rectangular body and is provided with two cavities a and b. The cavity b used for recovering and storing the reaction liquid flowing back and cooling down the temperature is connected to the overflow pipe 8 . A communication valve 17 is provided at the lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com