Foaming agent based on cyclohexanone by-product spent lye as well as preparation method and application of foaming agent

A technology of foaming agent and cyclohexanone, which is applied to the foaming agent based on cyclohexanone by-product waste lye and its preparation method and application field, which can solve the problems of wide foaming temperature range and poor foaming effect , to achieve a good foaming effect and realize the effect of resource reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

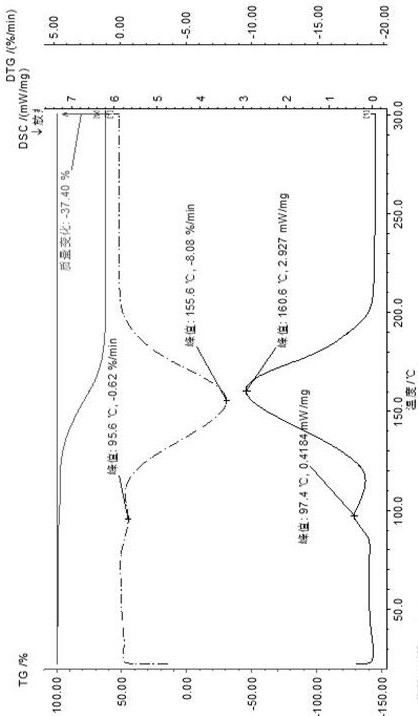

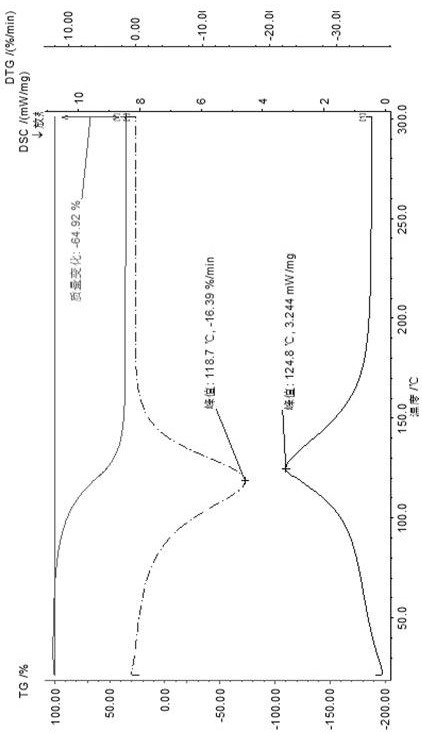

Image

Examples

Embodiment 1

[0029] The raw material cyclohexanone waste lye contains 60% by weight of water, a total of 20% by mass of sodium carbonate and sodium hydroxide, and the rest of the components are sodium adipate, sodium valerate, cyclohexanone, and cyclohexanol .

[0030] Heat 20L of cyclohexanone waste lye in a reaction kettle to 80°C, stir for 4 hours until there is no peculiar smell, and the tail gas is adsorbed and purified by an adsorption device. Then pass the treated cyclohexanone waste lye into the reaction kettle to bubble and stir with carbon dioxide, maintain the pressure at 2MPa, the reaction temperature at 25°C, and the reaction time for 4h to prepare a foaming agent.

[0031] The prepared foaming agent product had a pH value of 8, a viscosity of 100 centipoise, and a mass ratio of foaming volume of 30%.

[0032] The foaming agent of the present invention is mixed with a polymerization catalyst, a flame retardant, a foam stabilizer, and a polyol ether to form a foaming compositi...

Embodiment 2

[0034] The raw material cyclohexanone waste lye contains 30% by weight of water, contains 40% by mass of sodium carbonate and sodium hydroxide, and the rest of the components are sodium adipate, sodium valerate, cyclohexanone, and cyclohexanol .

[0035] Heat 50L of cyclohexanone waste lye in a reactor to 120°C, stir for 4 hours until there is no peculiar smell, and the tail gas is absorbed and purified by an adsorption device. Then pass the treated cyclohexanone waste lye into the reactor to bubble and stir with carbon dioxide, maintain the pressure at 1 MPa, the reaction temperature at 40°C, and the reaction time for 8 hours to prepare a foaming agent.

[0036] The prepared foaming agent product had a pH value of 9, a viscosity of 400 centipoise, and a foaming volume mass ratio of 50%.

[0037] The foaming agent of the present invention is mixed with a polymerization catalyst, a flame retardant, a foam stabilizer, and a polyol to form a foaming composition, which is added t...

Embodiment 3

[0039] The raw material cyclohexanone waste lye contains 50% by weight of water, a total of 30% by mass of sodium carbonate and sodium hydroxide, and the rest of the components are sodium adipate, sodium valerate, cyclohexanone, and cyclohexanol .

[0040] Heat 20L cyclohexanone waste lye in a reaction kettle to 100°C, stir for 6 hours until there is no peculiar smell, and the tail gas is absorbed and purified by an adsorption device. Then pass the treated spent cyclohexanone lye into the reactor to bubble and stir with carbon dioxide, maintain the pressure at 0.1 MPa, react at a temperature of 35° C., and react for 6 hours to prepare a blowing agent.

[0041] The prepared foaming agent product had a pH value of 8, a viscosity of 200 centipoise, and a foaming volume mass ratio of 40%.

[0042] The foaming agent of the present invention is mixed with a polymerization catalyst, a flame retardant, a foam stabilizer and a polyol ether to form a foaming composition, which is added...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com