Method of recovering antioxidant 1024 intermediate

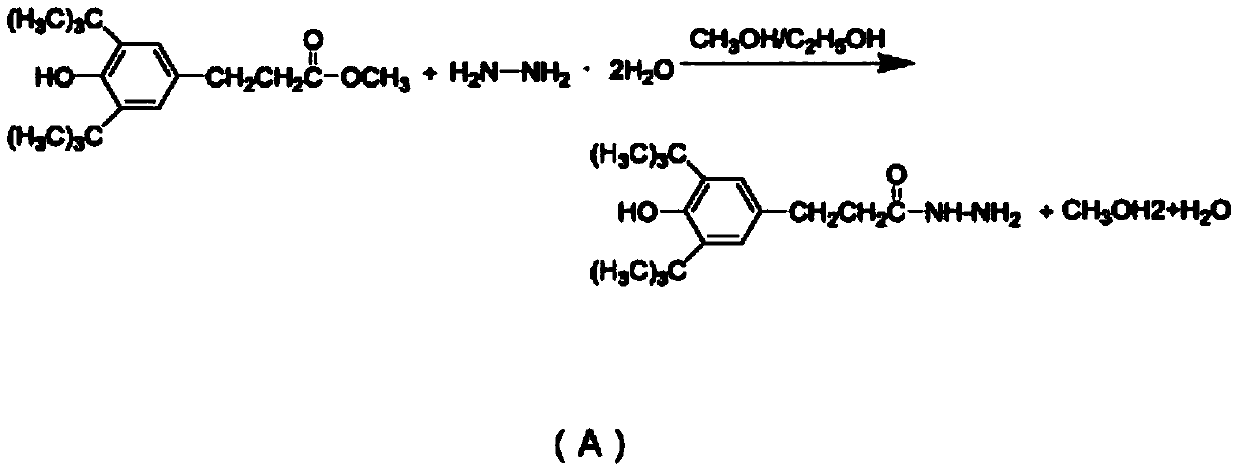

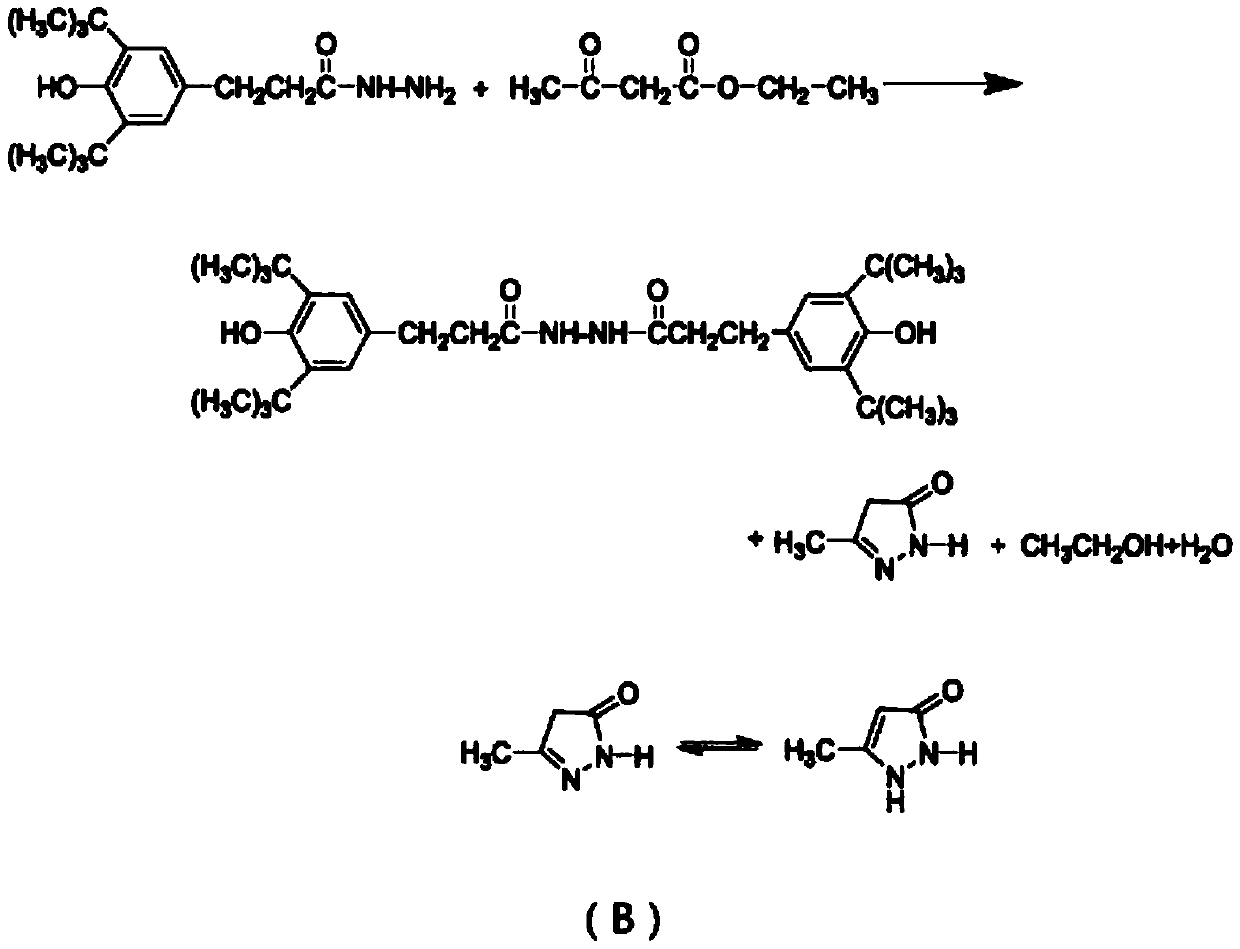

A technology for antioxidants and intermediates, which is applied in the field of recycling antioxidant 1024 intermediates, can solve the problems that antioxidant 1024 has a great influence on product purity, is prone to chemical reactions, and is difficult to recycle and reuse, so as to achieve resource recovery. The effect of reuse, easy separation and extraction, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A method for reclaiming antioxidant 1024 intermediates, comprising the following steps:

[0035] S1, pretreatment: Pour 500kg of antioxidant 1024 reaction waste liquid into the reactor, which is fixed with a thermometer, a reflux condenser, a feeder and an inert gas protection device, and is carried out by using a stirring device in the reactor. Mechanical stirring, so that the reaction waste liquid mixed evenly;

[0036] S2. Primary solid-liquid separation: add 62.5kg of anhydrous sodium sulfate into the reactor through the feeder on the reactor, and after fully stirring through the stirring device, cool down until crystals are precipitated, and then continue to cool down to 0°C to wait for crystals After complete precipitation, the reaction waste liquid is transported to a centrifuge for centrifugation to obtain sodium sulfate decahydrate and reaction waste liquid I;

[0037] S3, a vacuum distillation: transfer the reaction waste liquid I obtained in the above steps ...

Embodiment 2

[0043] A method for reclaiming antioxidant 1024 intermediates, comprising the following steps:

[0044] S1, pretreatment: Pour 500kg of antioxidant 1024 reaction waste liquid into the reactor, which is fixed with a thermometer, a reflux condenser, a feeder and an inert gas protection device, and is carried out by using a stirring device in the reactor. Mechanical stirring, so that the reaction waste liquid mixed evenly;

[0045] S2. Primary solid-liquid separation: Add 78.8kg of anhydrous sodium sulfate into the reactor through the feeder on the reactor, and after fully stirring through the stirring device, cool down until crystals are precipitated, and then continue to cool down to 0°C to wait for crystals After complete precipitation, the reaction waste liquid is transported to a centrifuge for centrifugation to obtain sodium sulfate decahydrate and reaction waste liquid I;

[0046] S3, a vacuum distillation: transfer the reaction waste liquid I obtained in the above steps ...

Embodiment 3

[0052] A method for reclaiming antioxidant 1024 intermediates, comprising the following steps:

[0053] S1, pretreatment: Pour 500kg of antioxidant 1024 reaction waste liquid into the reactor, which is fixed with a thermometer, a reflux condenser, a feeder and an inert gas protection device, and is carried out by using a stirring device in the reactor. Mechanical stirring, so that the reaction waste liquid mixed evenly;

[0054] S2. Primary solid-liquid separation: Add 85.3kg of anhydrous sodium sulfate into the reactor through the feeder on the reactor, and after fully stirring through the stirring device, cool down until crystals are precipitated, and then continue to cool down to 0°C to wait for crystals After complete precipitation, the reaction waste liquid is transported to a centrifuge for centrifugation to obtain sodium sulfate decahydrate and reaction waste liquid I;

[0055] S3, a vacuum distillation: transfer the reaction waste liquid I obtained in the above steps ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com