A new type of interlayer adhesive and preparation method and its application in interlayer spraying in papermaking

A technology of interlayer bonding and interlayer spraying, applied in textiles and papermaking, papermaking, papermaking and other directions, can solve problems such as quality improvement restrictions, increase burst strength, reduce environmental pollution, and realize resource recycling and reuse Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

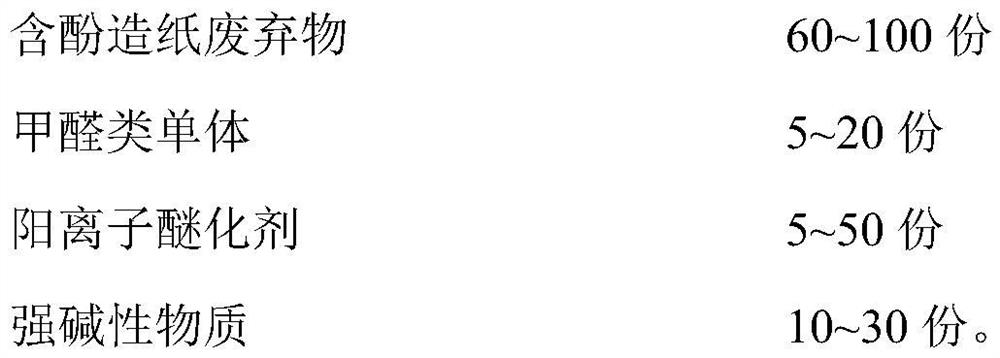

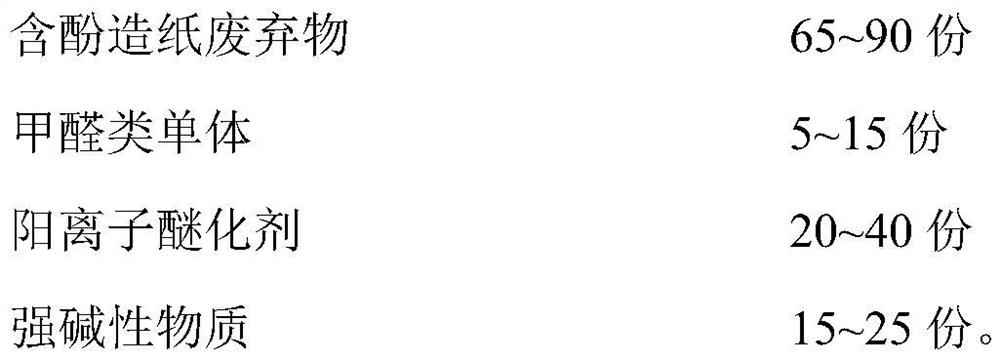

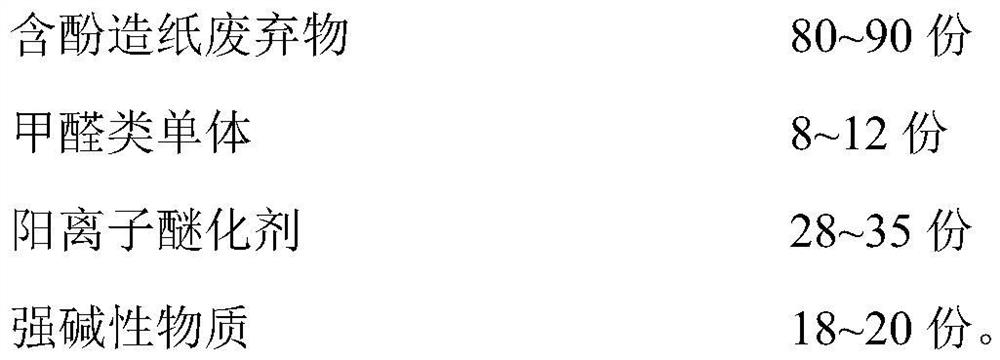

Method used

Image

Examples

Embodiment 1

[0031] (1) Preparation of new interlayer adhesive:

[0032] (1) 60 parts of papermaking waste containing phenolic substrates, 20 parts of formaldehyde and 10 parts of sodium hydroxide mixed solution were reacted at 70° C. for 300 minutes;

[0033] (2) Then add 10 parts of cationic etherification agent 2,3-epoxypropyl tertiary amine compound, 3-chloro-2-hydroxypropyl tertiary amine compound in (1) reaction product, react for 300 minutes at 70 ℃, After cooling and filtering, a new type of interlayer bonding glue was prepared. The prepared novel interlayer bonding glue has a solid content of 12%, a viscosity of 250 cps, and a pH of 4.05.

[0034] (2) The novel interlayer bonding glue prepared in this example is applied on a machine in a bobbin paper factory in Shandong

[0035] (1) Experimental production conditions:

[0036] Paper machine type: stacked net paper machine;

[0037] Production speed: about 270m / min;

[0038] Papermaking width: 2650mm;

[0039] Production pape...

Embodiment 2

[0050] (1) Preparation of new interlayer adhesive:

[0051] (1) 80 parts of papermaking waste containing phenolic substrates, 5 parts of paraformaldehyde and 5 parts of potassium hydroxide mixed solution were reacted at 80° C. for 200 minutes;

[0052] (2) Then add 10 parts of cationic etherification agent β-haloalkyl tertiary amine compound and 2,3-epoxypropyl tertiary amine compound to the reaction product of (1), react at 80°C for 200 minutes, after cooling and filtering A new type of interlayer adhesive was prepared. The solid content of the novel interlayer bonding glue prepared in this example is 15%, the viscosity is 348 cps, and the pH is 4.18.

[0053] (2) The new type of interlayer bonding glue prepared in this example is applied on a machine in a bobbin paper factory in Zhejiang

[0054] (1) Experimental production conditions:

[0055] Paper machine type: 3200mm multi-cylinder paper machine;

[0056] Paper machine speed: 117m / min;

[0057] Production paper type...

Embodiment 3

[0069] (1) Preparation of new interlayer adhesive

[0070] (1) 100 parts of papermaking waste containing phenolic substrates, 5 parts of paraformaldehyde and sodium hydroxide, and 15 parts of ammonia water mixed solution were reacted at 85°C for 60 minutes;

[0071] (2) Then add 20 parts of cationic etherification agent 2,3-epoxypropyl quaternary ammonium compound, 3-chloro-2-hydroxypropyl quaternary ammonium in (1) reaction product again, 90 ℃ of reaction 120 minutes, through After cooling and filtering, a new type of interlayer bonding glue was prepared. The new interlayer bonding glue prepared in this example has a solid content of 18%, a viscosity of 483 cps, and a pH of 5.63.

[0072] (2) The new type of interlayer bonding glue prepared in this example is applied on the recycled kraft cardboard of a factory in Shandong

[0073] (1) Experimental production conditions:

[0074] Paper machine type: 6600mm stacked net paper machine;

[0075] Paper machine speed: 970m / min;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com