C/gamma-Fe2O3 composite material recycling method

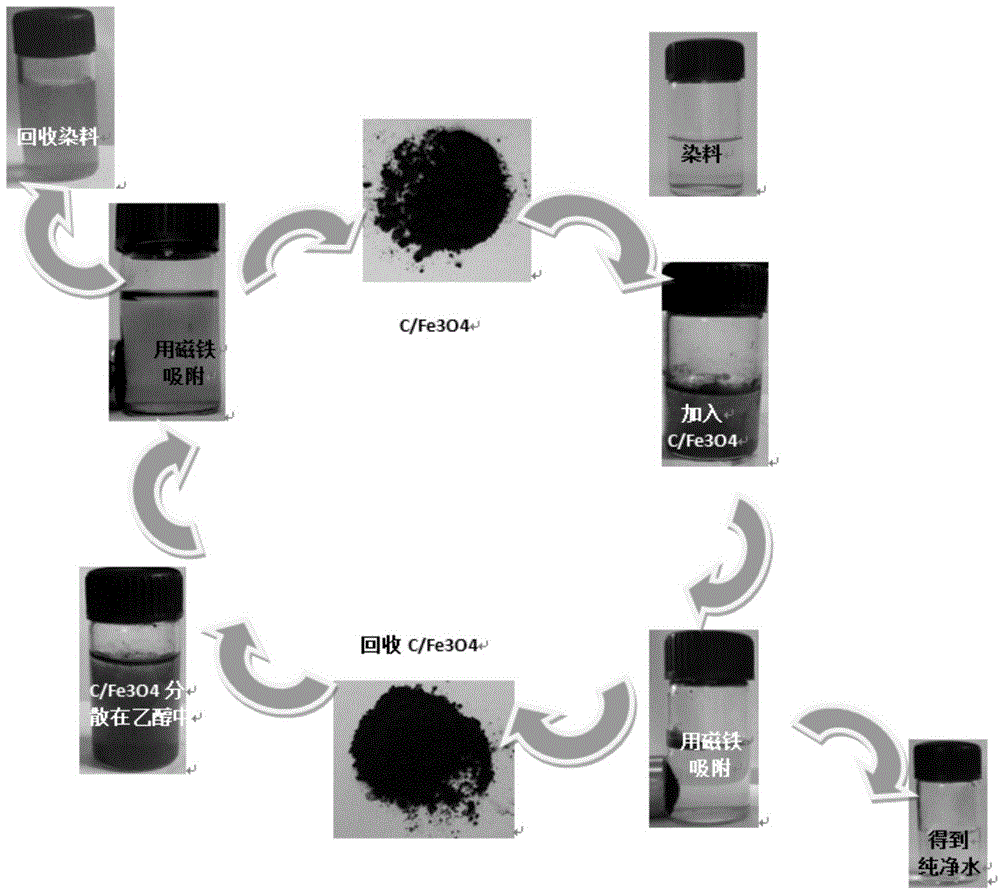

A composite material, -fe2o3 technology, applied in the field of recycling of C/γ-Fe2O3 composite materials, can solve problems such as difficult regeneration, achieve easy operation, convenient regeneration and use, and realize the effect of resource recycling and reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: A kind of C / γ-Fe 2 o 3 The method for recycling composite materials, the treatment and regeneration of water body oil slick pollution, includes the following steps:

[0034] 1) Apply electricity to the 2T electromagnet, and the C / γ-Fe 2 o 3 The material is adsorbed on the electromagnet,

[0035] 2) The electromagnet is powered off, and the C / γ-Fe 2 o 3 Sprinkled on the surface of oil slick in water body, C / γ-Fe 2 o 3 The addition amount of the composite material is oil pollution and C / γ-Fe 2 o 3 The mass ratio of powder is 20:1,

[0036] 3) For (2) step, C / γ-Fe has been sprinkled 2 o 3 The water body of the material is stirred by bubbling, so that the C / γ-Fe 2 o 3 Fully absorb oil slick,

[0037] 4) After the electromagnet is energized, the C / γ-Fe that absorbs the oil 2 o 3 Composite materials for magnetic recycling,

[0038] 5) The electromagnet is powered off, and the recovered (4) sample is dispersed in an acetone solvent, and stirred b...

Embodiment 2

[0040] Embodiment 2: A kind of C / γ-Fe 2 o 3 The method for recycling composite materials, the treatment and regeneration of water body oil slick pollution, includes the following steps:

[0041] 1) Apply electricity to the 2T electromagnet, and the C / γ-Fe 2 o 3 The material is adsorbed on the electromagnet,

[0042] 2) The electromagnet is powered off, and the C / γ-Fe 2 o 3 Sprinkled on the surface of the water dye pollution zone, C / γ-Fe 2 o 3 The addition amount of the composite material is oil pollution and C / γ-Fe 2 o 3 The mass ratio of powder is 38:1.

[0043] 3) For (2) step, C / γ-Fe has been sprinkled 2 o 3 The water body of the material is stirred by bubbling, so that the C / γ-Fe 2 o 3 Fully adsorb the dye,

[0044] 4) After the electromagnet is energized, the C / γ-Fe that adsorbs the dye 2 o 3 Composite materials for magnetic recycling,

[0045] 5) The electromagnet is powered off, and the recovered (4) sample is dispersed in chloroform solvent, and stirre...

Embodiment 3

[0047] Embodiment 3: A kind of C / γ-Fe 2 o 3 The method for recycling composite materials, the treatment and regeneration of water body oil slick pollution, includes the following steps:

[0048] 1) Apply electricity to the 2T electromagnet, and the C / γ-Fe 2 o 3 The material is adsorbed on the electromagnet,

[0049] 2) The electromagnet is powered off, and the C / γ-Fe 2 o 3 Sprinkled on the surface of the water dye pollution zone, C / γ-Fe 2 o 3 The addition amount of the composite material is oil pollution and C / γ-Fe 2 o 3 The mass ratio of powder is 35:1.

[0050] 3) For (2) step, C / γ-Fe has been sprinkled 2 o 3 The water body of the material is stirred by bubbling, so that the C / γ-Fe 2 o 3 Fully adsorb the dye,

[0051] 4) After the electromagnet is energized, the C / γ-Fe that adsorbs the dye 2 o 3 Composite materials for magnetic recycling,

[0052] 5) The electromagnet is powered off, and the recovered (4) sample is dispersed in an ethanol solvent, and stirre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com