Method and application for solid-liquid separation treatment of waste drilling fluid

A waste drilling fluid, solid-liquid separation technology, applied in the direction of centrifugal separation water/sewage treatment, mining wastewater treatment, mechanical oscillation water/sewage treatment, etc., can solve the problems of promotion and application limitations, high cost, and environmental hazards, etc. Achieve the effects of strong operability, simple treatment process and low treatment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

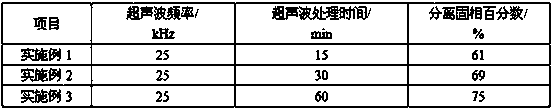

[0026] Example 1: When the waste polysulfide drilling fluid is not subjected to ultrasonic treatment, the percentage of solid phase content that can be separated by centrifuge treatment, a certain amount of waste polysulfide drilling fluid is put in the centrifuge, and the centrifuge speed is 2000 r / min, The centrifugation time was 10 min, and the mass of the solid phase of the centrifuged sample was measured by an electronic balance, and the percentage of the mass of the separated solid phase to the mass of the sample was calculated, and the percentage of the separated solid phase was 30%, as shown in Table 1.

Embodiment 2

[0027] Example 2: Without ultrasonic treatment, the percentage of solid phase content that can be separated from waste polysulfide drilling fluid after centrifuge treatment under different centrifuge centrifugation time, according to the method of centrifuge treatment Example 1, the difference is that, respectively, use 20 min, 40 min, 60 min instead of 10 min, so as to obtain the percentage of the solid phase mass separated from the waste polysulfide drilling fluid in different centrifugation times to the sample mass, take a certain amount of waste polysulfide drilling fluid in the centrifuge, and The speed of the centrifuge is 2000 r / min, the centrifugation time is 20 min, the percentage of the separated solid phase is 33%, the speed of the centrifuge is 2000 r / min, the centrifugation time is 40 min, the percentage of the separated solid phase is 34%, and the speed of the centrifuge is 2000 r / min, the centrifugation time is 60 min, and the percentage of separated solid phase...

Embodiment 3

[0028] Example 3: Without ultrasonic treatment, the percentage of solid phase content that can be separated from the waste polysulfide drilling fluid at different centrifuge centrifugal speeds after centrifuge treatment, according to the method of centrifuge treatment Example 1, the difference is that, respectively, use 20 min, 40 min, 60 min instead of 10 min, so as to obtain the percentage of the solid phase mass separated from the waste polysulfide drilling fluid in different centrifugation times to the sample mass, take a certain amount of waste polysulfide drilling fluid in the centrifuge, and The speed of the centrifuge is 3000 r / min, the centrifugation time is 10 min, and the percentage of the separated solid phase is 43%. The speed of the centrifuge is 4000 r / min, the centrifugation time is 10 min, and the percentage of the separated solid phase is 45%, as shown in Table 1.

[0029] Table 1 Comparison of treatment effects of waste sulfide drilling fluid with different c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com