Waste salt resourceful treatment system and treatment method thereof

A processing system and recycling technology, applied in the waste salt recycling processing system and its processing field, can solve the problems of low utilization rate of CO2, and achieve the effects of better product quality, wide application range and simple reaction equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

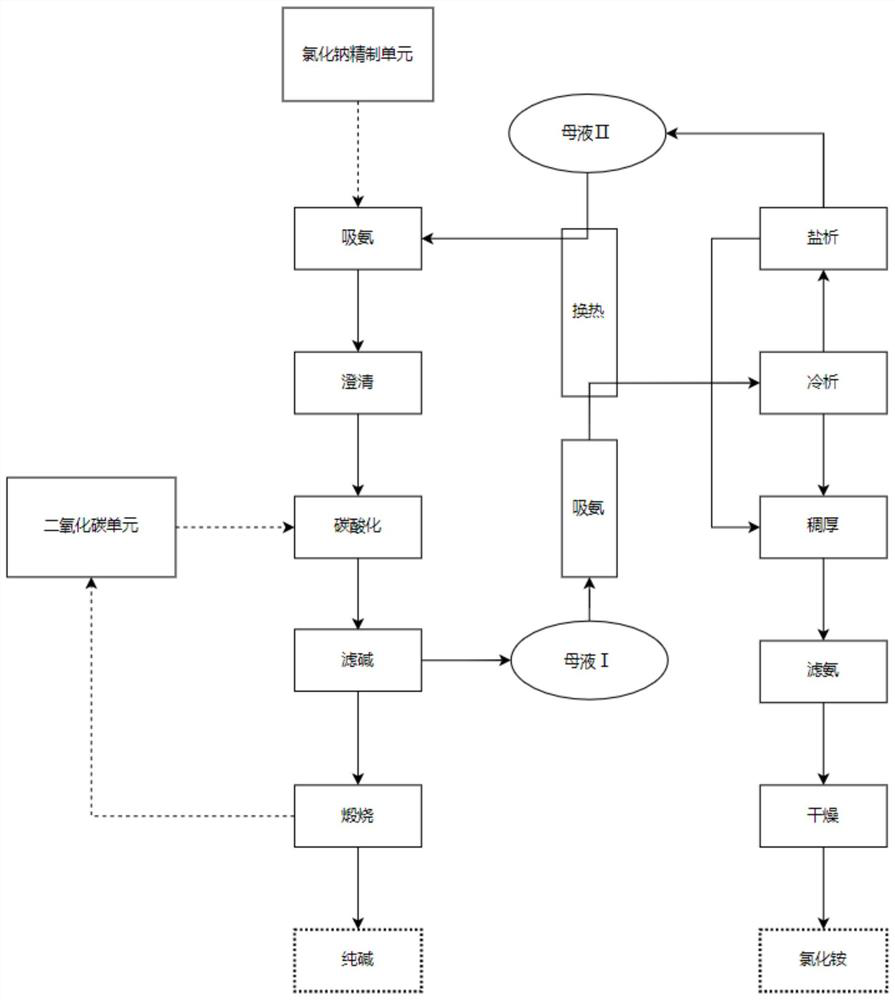

Method used

Image

Examples

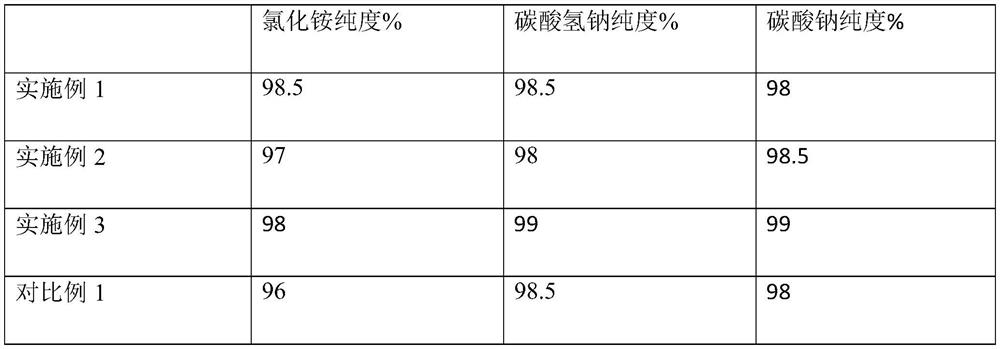

Embodiment 1

[0111] A method for recycling waste salt, specifically comprising the following steps:

[0112] S1, sodium chloride refining

[0113] S11. Low-temperature carbonization: Carry out low-temperature carbonization on the waste salt to remove organic matter. The low-temperature carbonization temperature is 200-500° C. to obtain waste sodium chloride salt with a TOC content of less than 30 mg / kg;

[0114] S12, water washing: add water to the sodium chloride waste salt obtained in step S11, dissolve, and obtain a waste salt solution with a mass fraction of 10-20%, add heavy metal precipitant, sodium carbonate and quicklime to the waste salt solution, soften and wash with water, remove Heavy metals and calcium and magnesium ions to obtain softened waste liquid;

[0115] S13. Membrane filtration: performing ultrafiltration, nanofiltration and reverse osmosis on the softened waste liquid obtained in step S12 to obtain a concentrated filtration solution;

[0116] S14, crystallization: ...

Embodiment 2

[0130] A waste salt recycling treatment method, the difference from Embodiment 1 is:

[0131] S3, resource utilization

[0132] S31, preparation of sodium bicarbonate: at normal temperature (25° C.), add water to the refined sodium chloride obtained in step S1 to form a saturated brine solution; cool the saturated brine solution, send it into the ammonia absorption tower, and utilize the ammonia gas and the saturated brine solution Countercurrent contact for ammonia absorption, FNH control 3 / TCl - The value of the value of 1.12 is taken as 1.12, and the ammonia brine solution with a temperature of 68°C is obtained; the obtained ammonia brine is sent to the cleaning tower, and the temperature is lowered to 40°C, and the scale on the tower body and the cooling pipe wall in the ammonia brine solution is removed, and the desired Carbonated brine: send the obtained pre-carbonated brine into the carbonization tower, and pass into the carbon dioxide obtained in step S2 for carbona...

Embodiment 3

[0140] A waste salt recycling treatment method, the difference from Embodiment 1 is:

[0141] S3, resource utilization

[0142] S31, preparation of sodium bicarbonate: at normal temperature (25° C.), add water to the refined sodium chloride obtained in step S1 to form a saturated brine solution; cool the saturated brine solution, send it into the ammonia absorption tower, and utilize the ammonia gas and the saturated brine solution Countercurrent contact for ammonia absorption, FNH control 3 / TCl - The value of 1.10 is taken as 1.10 to obtain an ammonia brine solution with a temperature of 65°C; the obtained ammonia brine is sent to a cleaning tower, and the temperature is lowered to 39°C to remove the scale on the tower body and the cooling pipe wall in the ammonia brine solution, and obtain the desired Carbonated brine: send the obtained pre-carbonated brine into the carbonization tower, and pass into the carbon dioxide obtained in step S2 for carbonation. According to act...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com