Technology for reclaiming low-concentration formaldehyde from pesticide wastewater through ionic liquid supported liquid membrane pervaporation-distillation coupling technology

An ionic liquid, supporting liquid membrane technology, applied in the separation/purification of carbonyl compounds, organic chemistry, chemical instruments and methods, etc., can solve the problems of the general application of advanced oxidation method, high operating cost, large consumption of oxidant, etc. To achieve the effect of solving treatment and discharge, simple production equipment, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

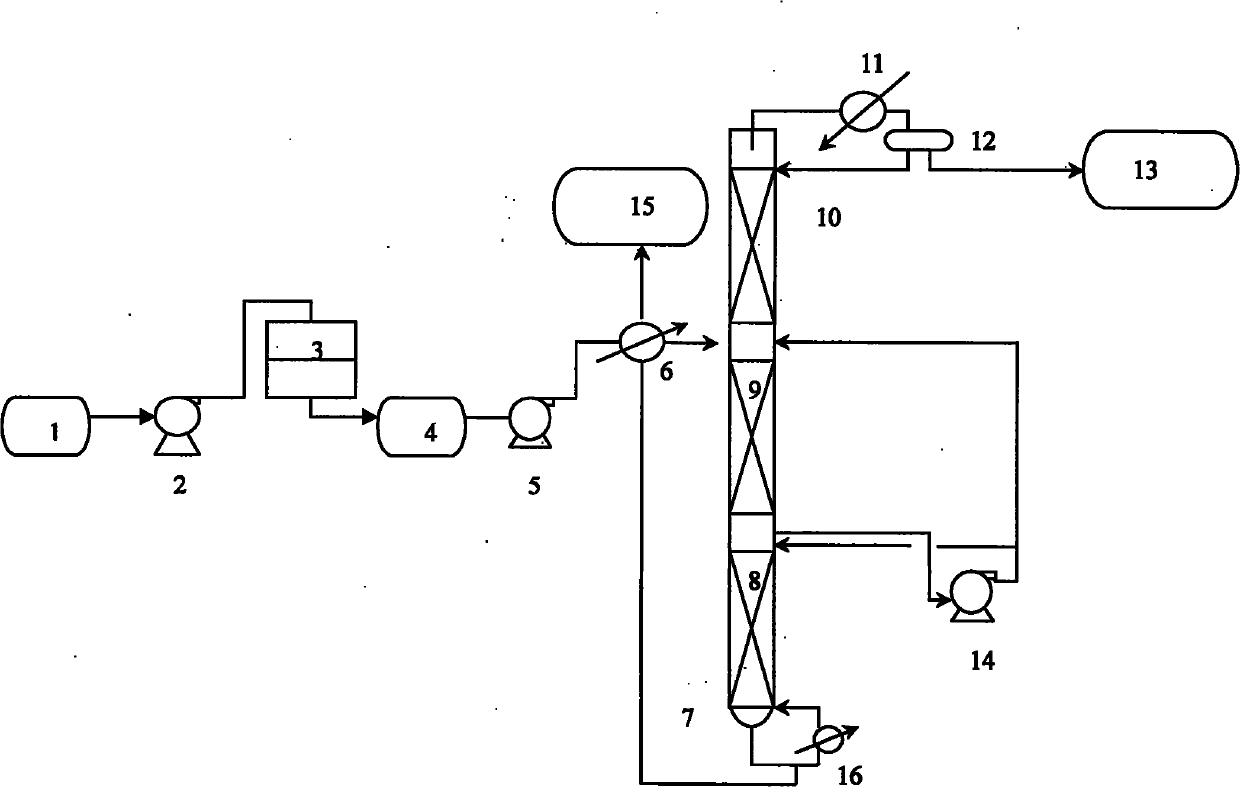

[0042] Embodiment 1. Concentrate and recover low-concentration formaldehyde solution by using pervaporation membrane module and rectification column coupling technology.

[0043] In this example, the pervaporation membrane module is used, and the self-made ionic liquid is used to support the liquid membrane, and the membrane liquid is the ionic liquid [C4mim] [PF 6 ], with the first step by the n-bromobutane of the amount of N-methylimidazole and other substances in the round bottom flask stirring reaction, bromoalkane will be slowly added dropwise, the reaction temperature is 70 ℃, after 24 hours of reaction, Cool to room temperature, wash 2-3 times with ethyl acetate, and finally wash off the ethyl acetate in the ionic liquid with ether to synthesize [C4mim]Br; the second step weighs a certain amount of synthesized imidazolium bromide salt and dissolves it in water, and adds an appropriate amount of KPF 6 , stirred and reacted for 12 hours, poured off the upper aqueous phas...

Embodiment 2

[0047] Embodiment 2. The film-making method is a decompression method. A certain amount of ionic liquid is placed above the bottom film and placed together in a vacuum drying oven. A pump is used to extract the air in the aperture below the film, and the vacuum is maintained for 24 hours. The membrane was suspended for 24 hours, and the excess ionic liquid on the surface was removed. In the process of pervaporation concentration of formaldehyde, the feed liquid temperature is 30°C, the permeate side pressure is 2100Pa, and other experimental conditions are the same as in Example 1. The experimental results are basically the same as in Example 1.

Embodiment 3

[0048] Embodiment 3. The film making method is the atmospheric pressure immersion method. The inert base film is soaked in an appropriate amount of ionic liquid, and the capillary force is used to make it penetrate into the pores. The film is suspended for 24 hours, and the excess ionic liquid on the surface is removed. In the process of pervaporation and concentration of formaldehyde, the temperature of the feed liquid is 40°C, and the pressure on the permeation side is 2500Pa. All the other experimental conditions were the same as in Example 1. The experimental results are basically the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com