Combined type tool for cutting tuyere second jacket of blast furnace

A combined and cutting tool technology, applied in the field of metallurgical equipment construction, can solve the problems of poor visibility of operations, unfavorable construction of energy-saving and environment-friendly steel enterprises, and easy generation of a large amount of dust and black smoke.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

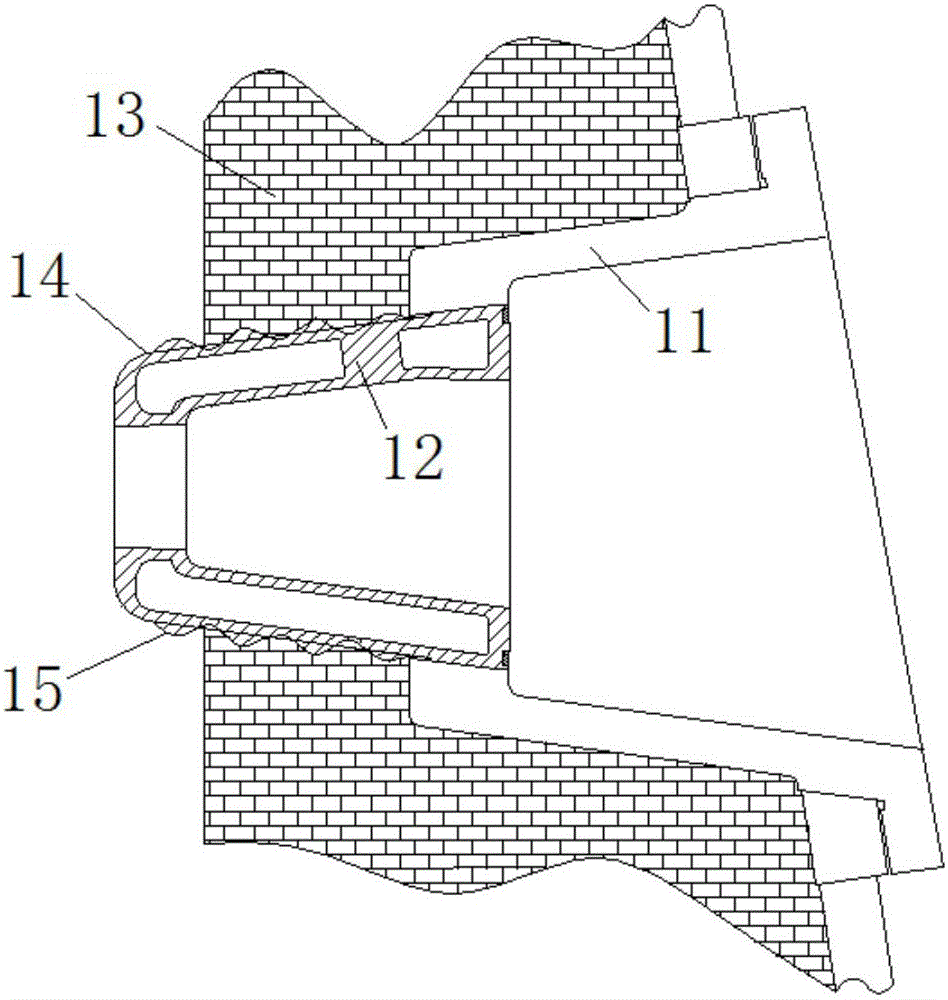

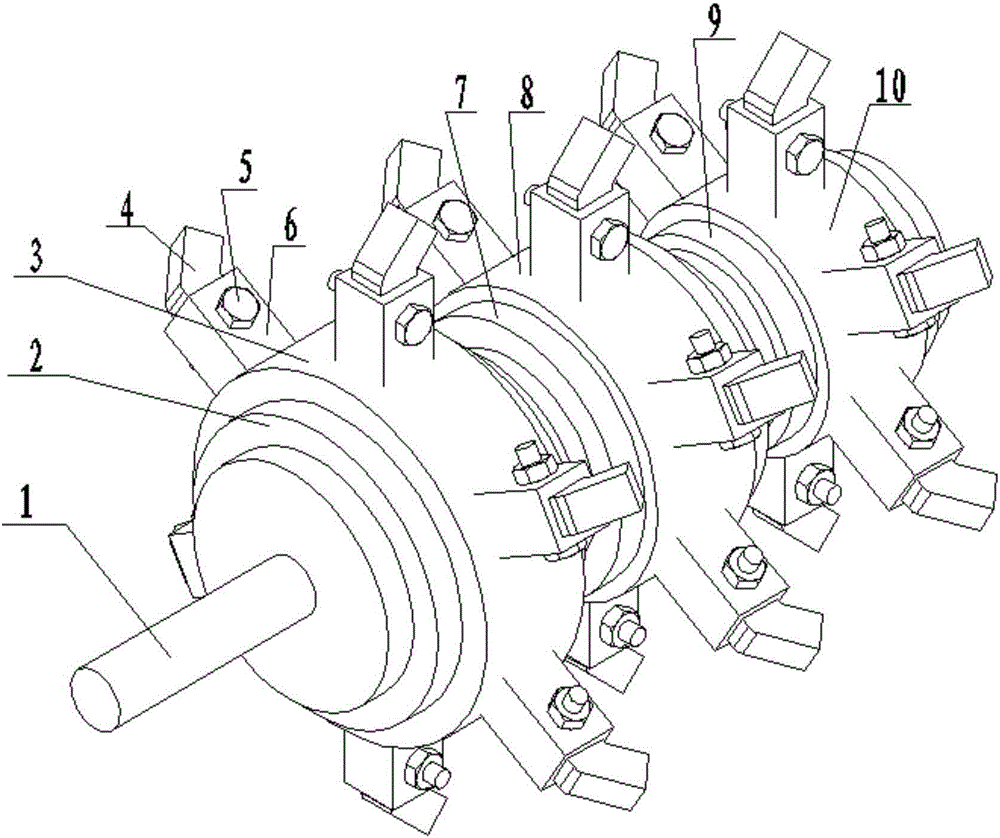

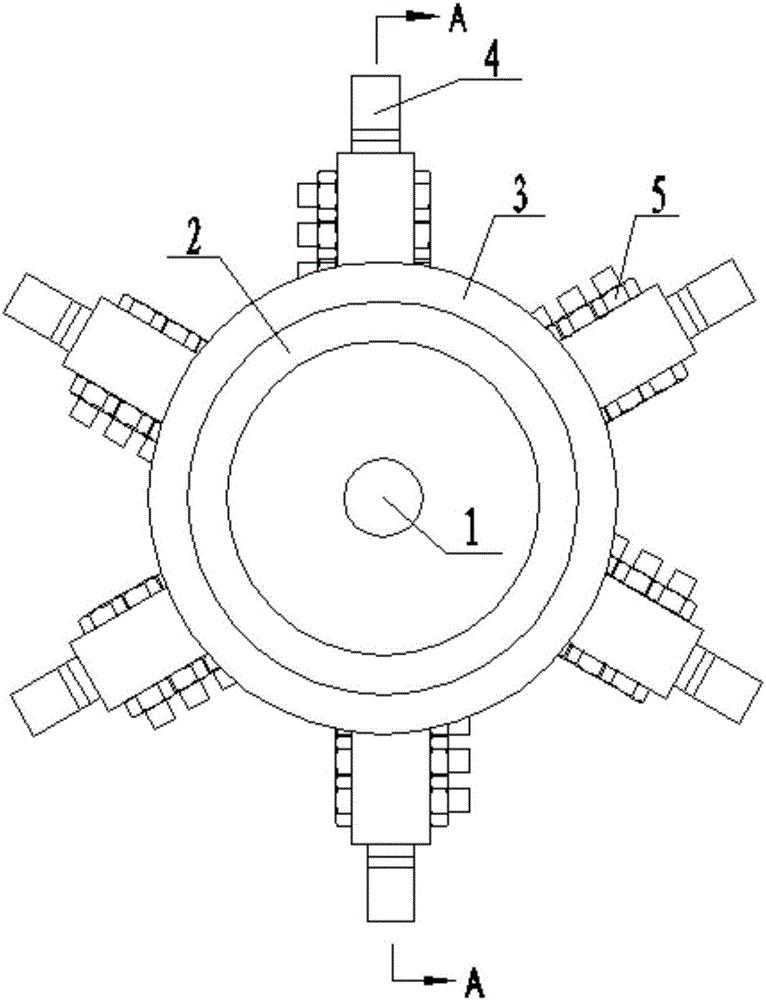

[0048]A combined tool for cutting two sets of blast furnace tuyeres, including a rotating shaft 1, a first thread 1.1, a large positioning ring 2, a second thread 2.1, a first tool mounting ring 3, a third thread 3.1, a tool 4, and a mounting hole 4.1 , Fixing bolt 5, tool positioning block 6, middle positioning ring 7, second tool mounting ring 8, small positioning ring 9, third tool mounting ring 10.

[0049] The tool rotation axis 1 has n step axes (1≤n≤15), and the diameters of the step axes can be equal or different; the cutting surface of the tool 4 on the step surface of the n step axes can be adjusted at 0-60°; The cross-section can be square, circular, oval, etc., and the longitudinal section of the cutter 4 can be L-shaped, linear, etc.; the fixing method of the cutter 4 can be bolted, pin-shaft connection, etc.;

[0050] The following is an example of a tool with three rotating shafts with different diameters of step shafts, a tool with a square cross section and an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com