Method for preparing M-phase VO2 by using inactivated vanadium battery positive electrolyte

A positive electrolyte and vanadium battery technology, applied in the field of vanadium dioxide, can solve the problems of vanadium ion concentration and sulfuric acid concentration exceeding the standard, vanadium ion valence mismatch, unusable and other problems, achieve high added value, easy promotion and application, and low cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

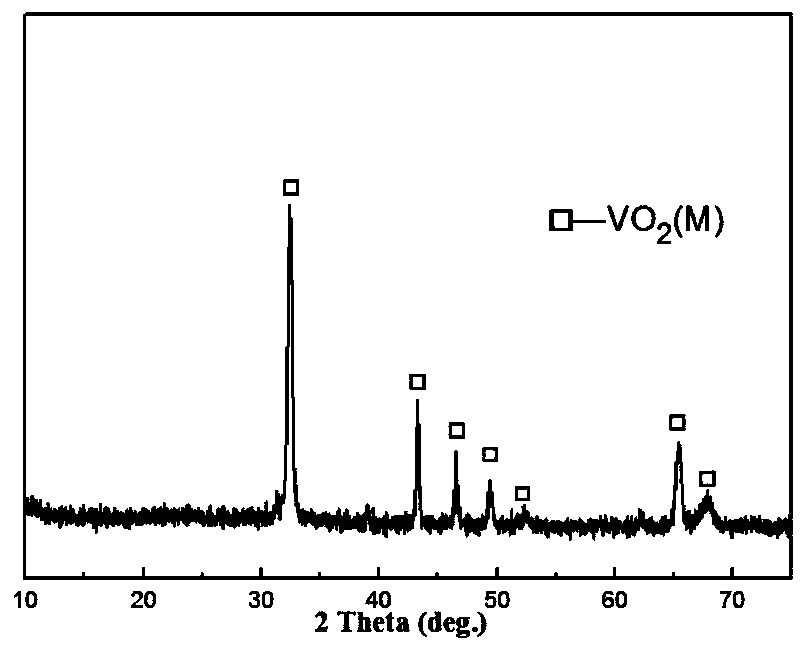

Image

Examples

Embodiment 1

[0027] Measure 500ml of 1# electrolyte and heat it to 70°C in the reaction vessel, and continuously feed high-purity SO into the electrolyte during slow stirring 2 Gas for 6h, after aeration, continue to insulate and stir for 30min to obtain a blue-black solution, and dropwise add NaOH solution to adjust the pH of the electrolyte to 4, filter to obtain a black precipitate, wash twice with deionized water, dry and grind to obtain a black powder, and Evenly spread on the bottom of the porcelain boat, place in a vacuum furnace, bake at 600°C for 5 hours, cool down to room temperature to obtain VO 2 48.4g, the total vanadium yield is 70.7%.

Embodiment 2

[0029] Measure 500ml of 1# electrolyte and heat it to 30°C in the reaction vessel, add 260g of vanadium sulfate V decahydrate to the electrolyte 2 (SO 4 ) 3 10H 2O, keep stirring for 3 hours to obtain a blue-black solution, and dropwise add ammonia water with a mass fraction of 25-28% to adjust the pH of the electrolyte to 3, filter to obtain a black precipitate, wash twice with deionized water, dry and grind to obtain a black powder , spread it evenly on the bottom of the porcelain boat, place it in an atmosphere furnace, and bake it at 650 ° C for 4 hours under the protection of argon gas, and continue to cool down to room temperature with argon gas to obtain VO 2 44.7g, the total vanadium yield is 65.3%.

Embodiment 3

[0031] Measure 500ml of 1# electrolyte and heat it to 100°C in the reaction vessel, add 87g of dihydrate oxalic acid H to the electrolyte 2 C 2 o 4 2H 2 O, keep stirring for 9h to obtain a blue-black solution, and add Na to it 2 CO 3 Adjust the pH of the electrolyte to 5, filter to obtain a black precipitate, wash it twice with deionized water, dry and grind to obtain a black powder, spread it evenly on the bottom of the porcelain boat, place it in a vacuum furnace, and bake it at 700°C for 3 hours. Cool down to room temperature to get VO 2 53.1g, the total vanadium yield is 77.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com