Acid etching wastewater treatment and recycling system

An acid etching waste liquid, etching technology, applied in photography process, instrument, photography auxiliary process and other directions, can solve the problems of decreased ammonia nitrogen content, low etching rate, crystallization and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

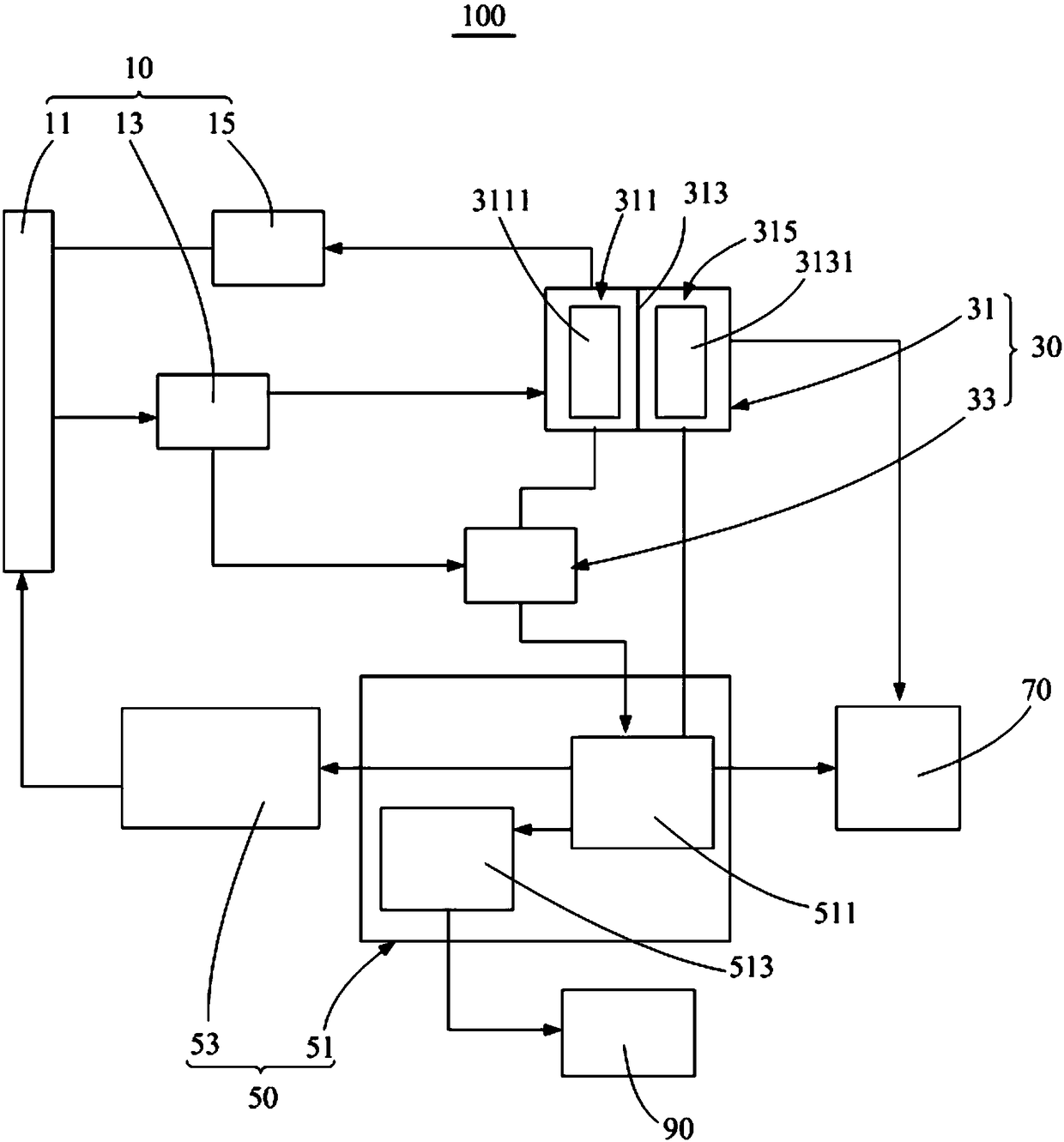

Image

Examples

Embodiment 1

[0045] The concentration of copper ions in the acidic etching waste liquid of a circuit board factory is 100g / L, the concentration of ammonia nitrogen is 12000ppm, the acid equivalent is 0.7N, the concentration of chloride ions is 211g / L, and the etching rate of the etching machine cylinder after the cylinder is newly opened is 48um / min; Then use 50L waste liquid, add 12000ppm copper-free sub-liquid to dilute, and then conduct electrolysis. The current is in the range of 10-20A and electrolyzes in four steps for 16 hours. At this time, the copper ion concentration of the catholyte is less than 1g / L, and ammonia nitrogen is 10800ppm, acid equivalent 1.5N, chloride ion concentration 186g / L, take 20L catholyte, add 100g ammonium chloride, 10mL etching additive to make regenerated sub-liquid, test in small etching machine tank, when regenerated sub-liquid replaces etching machine In the process of 50% of the etching solution in the tank, the etching rate fluctuates in the range of...

Embodiment 2

[0047] The concentration of copper ions in the acidic etching waste liquid of a circuit board factory in Jiangxi is 110g / L, the concentration of ammonia nitrogen is 6000ppm, the acid equivalent is 1.0N, and the concentration of chloride ions is 200g / L, measured after the etching machine cylinder is newly opened The etching rate is 36um / min; then use 20L waste liquid, dilute it with 6000ppm copper-free sub-solution, and then conduct electrolysis. The current is in the range of 10-20A and electrolyzes in four steps for 16h. At this time, the copper ion concentration of the catholyte is less than 1g / L. The concentration of ammonia nitrogen is 5400ppm, the acid equivalent is 1.9N, and the concentration of chloride ions is 177g / L. Take 20L of catholyte, add 45g of ammonium chloride, and 10mL of etching additives to make a regeneration daughter liquid. Test it in a small etching machine tank. When regeneration In the process of replacing 50% of the etching solution in the etching mac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com