Method for preparing V2O5 nano powder by using vanadium redox battery failure electrolyte

A technology for electrolyte preparation and V2O5, which is applied in the field of vanadium extraction, can solve the problems of excessive vanadium ion concentration and sulfuric acid concentration, mismatch of vanadium ion valence state, unusability, etc., and achieve simple process method, easy popularization and application, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Prepare 10L of pentavalent electrolyte solution diluted with deionized water through pre-charging and pre-oxidation for later use (1 # Electrolyte), where [VO 2 - ] is 0.8M~1.2M, VO 2- <0.1g / L, the electrolyte should be stored at 0-25°C;

[0031] Measure 500mL of 1 with a total vanadium concentration of 0.8M # Add 20.4g of sodium dodecylbenzenesulfonate to the electrolyte solution, transfer the solution to a hydrothermal reaction kettle, seal it and place it in an oven, and keep it warm at 100°C for 8 hours. After the reaction, use deionized water and anhydrous Water and ethanol were centrifuged and washed twice, and dried at a temperature of 50° C. for 8 hours to obtain 22.12 g of vanadium pentoxide powder.

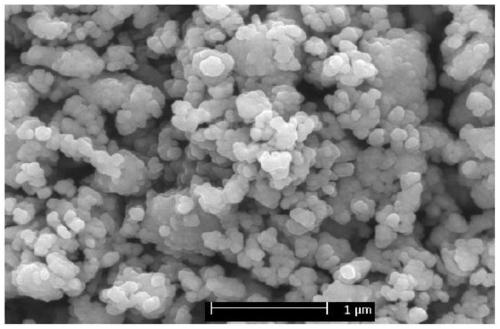

[0032] The particle size range of the vanadium pentoxide powder obtained in this example is 100-120 nm, and the vanadium yield is 60.77%.

Embodiment 2

[0034] Prepare 10L of pentavalent electrolyte solution diluted with deionized water through pre-charging and pre-oxidation for later use (1 # Electrolyte), where [VO 2 - ] is 0.8M~1.2M, VO2- <0.1g / L, the electrolyte should be stored at 0-25°C;

[0035] Measure 500mL of 1.0M total vanadium concentration # Electrolyte, add cetyltrimethylammonium bromide 7.5g, transfer the solution into a hydrothermal reaction kettle, seal it and place it in an oven, keep it warm at 110°C for 16h, after the reaction, wash it with deionized water and anhydrous ethanol, respectively, to be washed twice by centrifugation, and dried at a temperature of 60° C. for 12 hours to obtain 32.72 g of vanadium pentoxide powder.

[0036] The particle size range of the vanadium pentoxide powder obtained in this example is 110-150 nm, and the vanadium yield is 71.91%.

Embodiment 3

[0038] Prepare 10L of pentavalent electrolyte solution diluted with deionized water through pre-charging and pre-oxidation for later use (1 # Electrolyte), where [VO 2 - ] is 0.8M~1.2M, VO 2- <0.1g / L, the electrolyte should be stored at 0-25°C;

[0039] Measure 500mL of 1.2M total vanadium concentration # Electrolyte, add 0.5g of sodium dodecylsulfonate, transfer the solution into a hydrothermal reaction kettle, seal it and put it in an oven, keep it at a temperature of 120°C for 24 hours, after the reaction, use deionized water and anhydrous Each was centrifuged and washed twice with ethanol, and dried at a temperature of 80° C. for 10 hours to obtain 43.07 g of vanadium pentoxide powder.

[0040] The particle size range of the vanadium pentoxide powder obtained in this embodiment is 150-200 nm, and the vanadium yield is 78.88%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com