Wear-resistant high-strength plastic particles produced from waste plastic

A technology of high-strength plastics and waste plastics, which is applied in the field of waste plastic recycling and reuse, can solve problems such as low production efficiency and finished product qualification rate, affect the compatibility of recycled plastics, and reduce the mechanical properties of plastic particles, so as to achieve production efficiency and High qualified rate of finished products, fast resource recycling and reuse, and the effect of improving UV aging resistance and flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

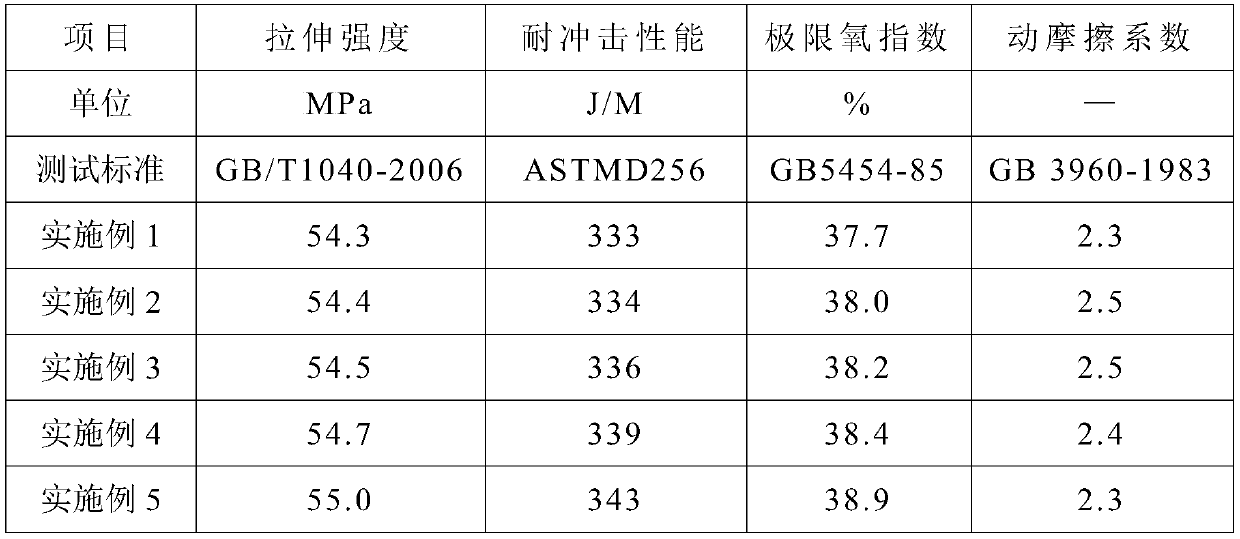

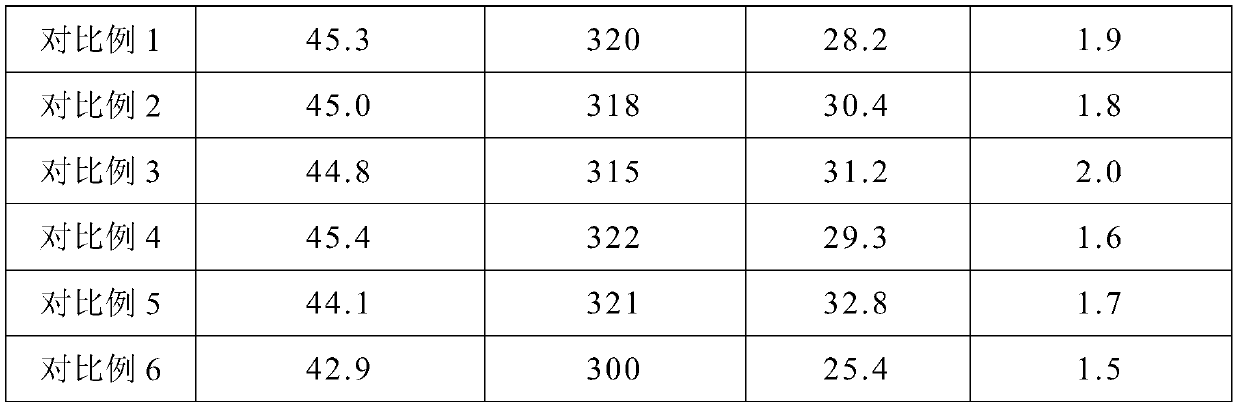

Examples

Embodiment 1

[0033] A process for producing wear-resistant high-strength plastic particles using waste plastics, characterized in that it includes the following steps:

[0034] Step S1. Pretreatment of waste plastics: Break the collected waste plastic products into pieces with a maximum length of no more than 3cm, add the plastic pieces to boiling water and boil for 20 minutes, take out the plastic pieces after cooling, and then quickly and clean the plastic pieces Put it into a ball mill and mill it at 300r / min for 100min. After ball milling, add water 30 times the weight of the mixture to the mixture and stir evenly. Ultrasonic clean at 50°C for 20min. Then put it in a vacuum drying oven at 110°C and dry it to constant weight, and then crush it through a 20-mesh sieve to obtain waste plastic powder; the cleaning agent is made by mixing the following raw materials in parts by weight: dodecylbenzene 5 parts of sodium sulfonate, 10 parts of lecithin, 5 parts of fatty acid sorbitan, 30 parts o...

Embodiment 2

[0039] A process for producing wear-resistant high-strength plastic particles using waste plastics, characterized in that it includes the following steps:

[0040] Step S1. Pretreatment of waste plastics: Break the collected waste plastic products into pieces with a maximum length of no more than 3.5 cm, add the plastic pieces to boiling water and boil for 22 minutes, take out the plastic pieces after cooling, and put the plastic pieces together quickly Mix the cleaning agent, put it into a ball mill and mill it at a speed of 320r / min for 110min, add water 35 times the weight of the mixture to the mixture after ball milling, stir evenly, ultrasonically clean at 55°C for 22min, centrifuge after cleaning, take the sediment, and wash it with water , and then placed in a vacuum drying oven at 113°C to dry to constant weight, and then crushed through a 25-mesh sieve to obtain waste plastic powder; the cleaning agent is made by mixing the following raw materials in parts by weight: d...

Embodiment 3

[0045] A process for producing wear-resistant high-strength plastic particles using waste plastics, characterized in that it includes the following steps:

[0046] Step S1, pre-treatment of waste plastics: crush the collected waste plastic products into fragments with a maximum length of no more than 4cm, add the plastic fragments to boiling water and boil for 25 minutes, take out the plastic fragments after cooling, and then quickly and clean the plastic fragments Put it into a ball mill and mill at 350r / min for 115min. After ball milling, add water 40 times the weight of the mixture to the mixture and stir evenly. Ultrasonic clean at 60°C for 25min. After cleaning, centrifuge to take the precipitate and wash it with water. Then put it in a vacuum drying oven at 115°C and dry it to constant weight, and then crush it through a 30-mesh sieve to obtain waste plastic powder; the cleaning agent is made by mixing the following raw materials in parts by weight: dodecylbenzene 8 part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com