Environment-friendly foaming material based on EVA waste material and treatment method of EVA waste material

A processing method and technology of foaming materials, applied in the field of organic polymer compounds, can solve problems such as waste of resources, achieve the effect of reducing waste, improving utilization rate, and light surface pattern

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

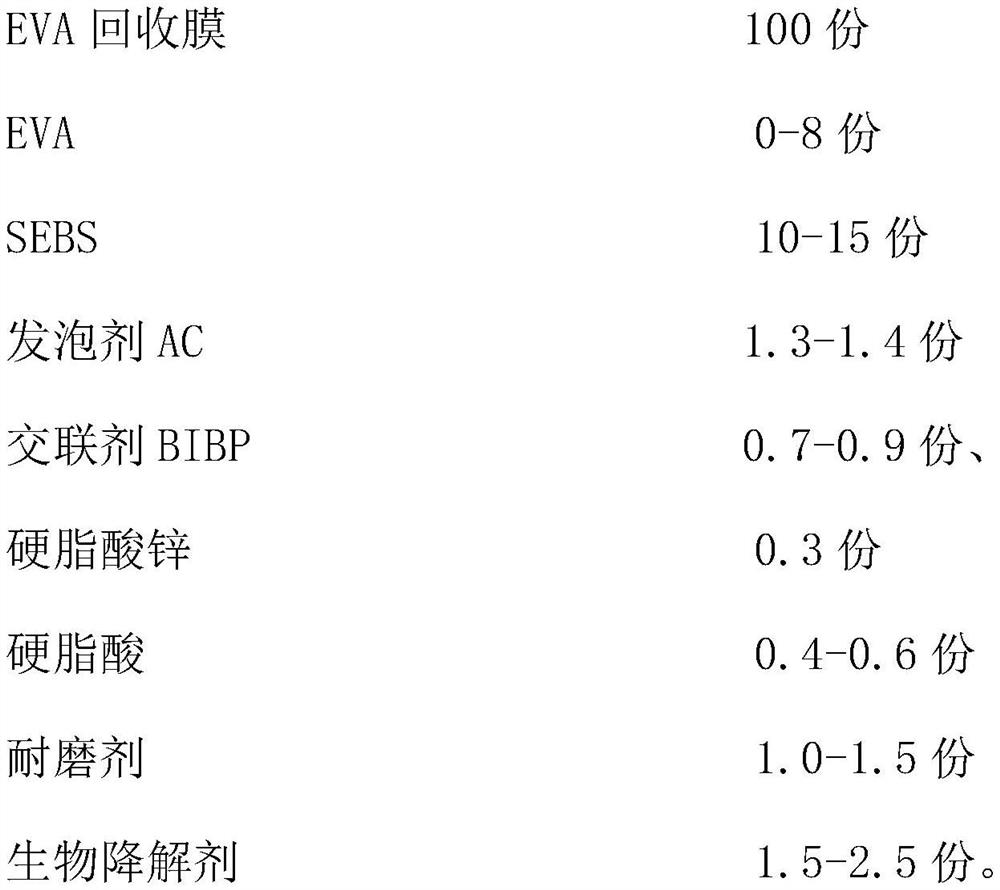

[0046]Its preparation method comprises the following steps: First mix other raw materials except the cross-linking agent BIBP and foaming agent AC uniformly, then carry out banburying, adjust the banburying temperature to be controlled at 86-91°C, keep for 4min, and then turn the material; The mixing temperature rises to 95°C, and the material is turned for the second time; when the banburying temperature rises to 101°C, the material is turned for the third time, and the cross-linking agent BIBP and foaming agent AC are added, and when the banburying temperature rises to 107°C, the second time Turn the material four times; when the mixing temperature rises to 112°C, turn the material for the fifth time, and then banbury for 1 minute, and finally pour the material, start refining, and granulate to obtain environmentally friendly foam rice, which is molded and foamed to produce environmentally friendly foam. bubble material.

[0047] Among them, SEBS is oil-free granular and has...

Embodiment 1

[0050] A processing method for EVA waste material, comprising the following steps:

[0051] Step 1: put waste EVA soles, waste EVA sheets, waste EVA scraps and other waste products into the crusher, and crush them to obtain blocky crushed materials with a length less than 7cm and a width of less than 5cm; then put the blocky crushed materials into the waste crusher , to obtain strip-shaped crushed material;

[0052] Step 2: Put the strip-shaped crushed material, sarin resin, and PMP obtained in step 1 into the internal mixer at a weight ratio of 85:4:8, and gradually increase the mixing temperature to a maximum temperature of 150°C, and the mixing time is 18 minutes. Obtain block banbury;

[0053] Step 3, processing the block-shaped banburying material after banburying through a screw extruder and an open mill to obtain an EVA recovery film;

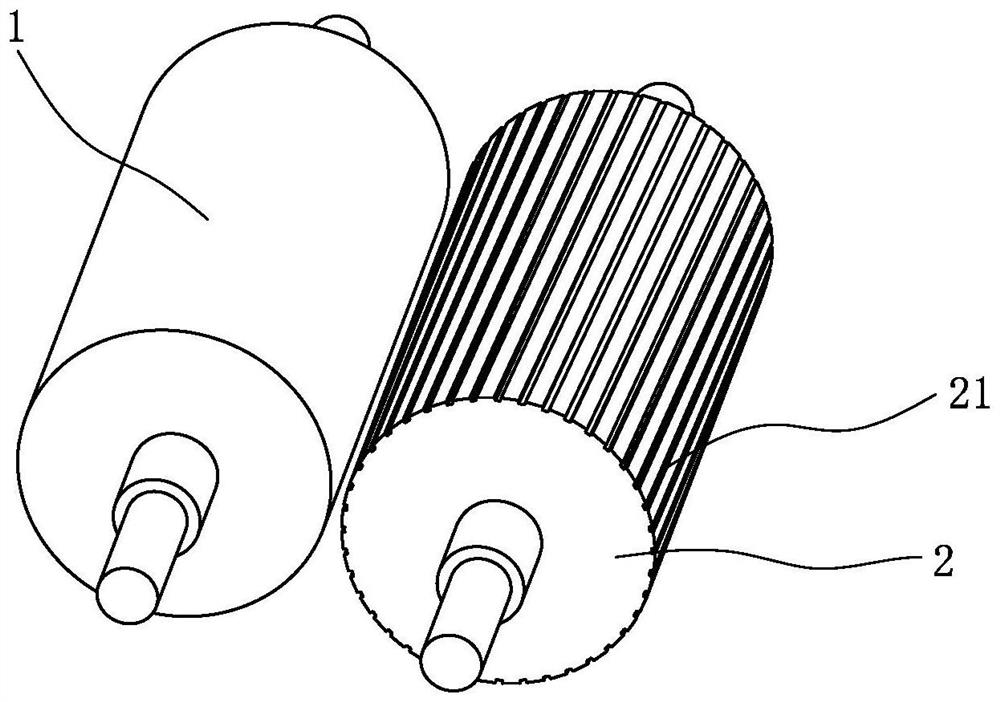

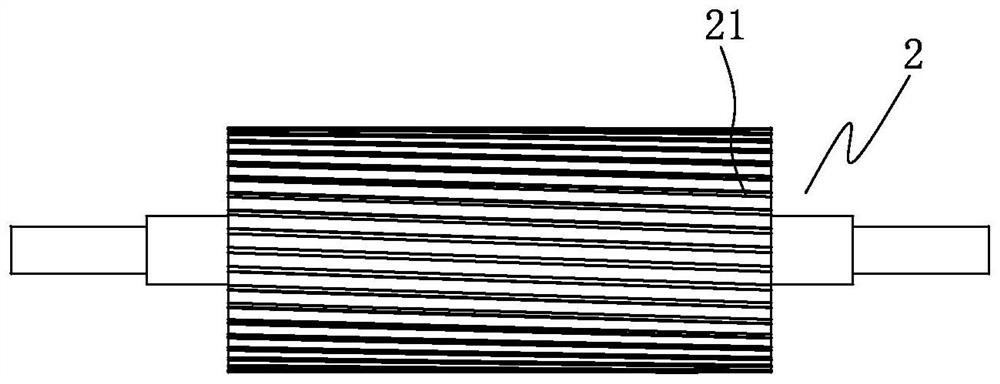

[0054] Among them, the crusher includes a crushing assembly for crushing the EVA waste material. The crushing assembly includes a fir...

Embodiment 2

[0062] A processing method for EVA waste material, comprising the following steps:

[0063] Step 1: put waste EVA soles, waste EVA sheets, waste EVA scraps and other waste products into the crusher, and crush them to obtain blocky crushed materials with a length less than 7cm and a width of less than 5cm; then put the blocky crushed materials into the waste crusher , to obtain strip-shaped crushed material;

[0064] Step 2: Put the strip-shaped crushed material, sarin resin, and PMP obtained in step 1 into the internal mixer at a weight ratio of 85:10:4, and gradually increase the mixing temperature to a maximum temperature of 150°C, and the mixing time is 25 minutes. Obtain block banbury;

[0065] Step 3, processing the block-shaped banburying material after banburying through a screw extruder and an open mill to obtain an EVA recovery film;

[0066] Among them, the crusher includes a crushing assembly for crushing the EVA waste material. The crushing assembly includes a fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com