Ammonia nitrogen recovery system for hair product wastewater and operating method of system

A technology for ammonia nitrogen recovery and hair products, which is applied in chemical instruments and methods, water/sewage treatment, heating water/sewage treatment, etc., can solve the problems of failure to realize high-concentration ammonia nitrogen recovery and reuse, waste of resources, etc. Small size, stable operation, simple operation and management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

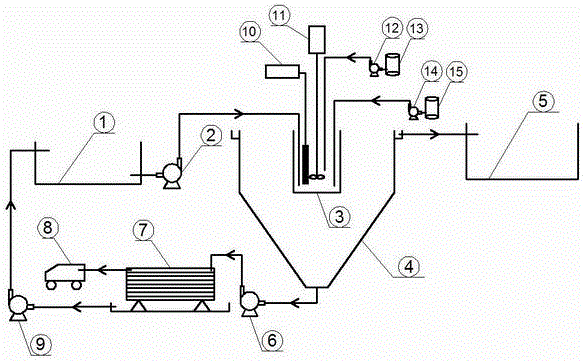

[0019] An ammonia nitrogen recovery system for hair product wastewater, including a high ammonia nitrogen wastewater tank 1, a sewage lift pump 2, a heating reaction tank 3, a reaction sedimentation tank 4, a mixed sewage tank 5, a sludge pump 6, and a plate and frame filter press 7 , transport truck 8, sewage return pump 9, electric heater 10, electric mixer 11, MgCl 2 Dosing metering pump 12, MgCl 2 Storage tank 13, Na 2 HPO 4 Dosing metering pump 14 and Na 2 HPO 4 The medicine storage tank 15, wherein the high-ammonia-nitrogen wastewater pool 1 communicates with the heating reaction pool 3 through the sludge lifting pump 2, and the heating reaction pool 3 is fixed in the reaction sedimentation pool 4, and the heating reaction pool 3 is a cylindrical cavity with an open upper end , the upper edge of the heating reaction tank 3 is flush with the upper edge of the reaction sedimentation tank 4, the lower edge of the heating reaction tank 3 is 2 meters away from the upper e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com