Maximum-thickness S355G10+N steel plate for ocean platform and production method of steel plate

A S355G10, offshore platform technology, applied in the field of structural steel plates for offshore engineering, to achieve the effects of high low-temperature impact energy, excellent mechanical properties, and no dirt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

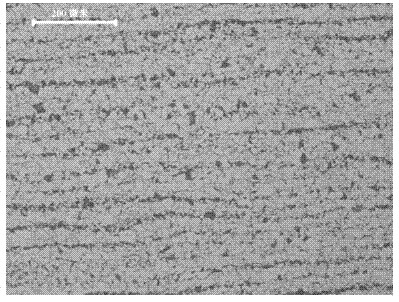

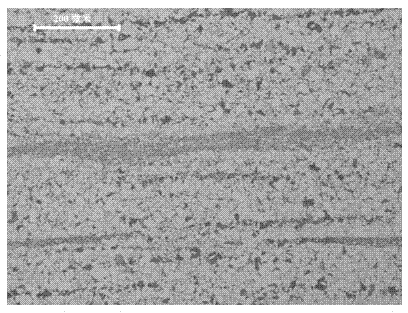

Image

Examples

Embodiment 1

[0032] Embodiment 1: The S355G10+N steel plate for the large-thickness offshore platform adopts the following composition ratio and production method.

[0033] The thickness of the S355G10+N steel plate is 150mm, and the composition content (wt) is: C 0.12%, Si 0.15%, Mn 1.63%, P 0.006%, S 0.001%, V 0.044%, Nb 0.028%, Al 0.047%, Ceq 0.40 %, Pcm 0.19%, the rest is Fe and unavoidable impurities.

[0034] The production method of this steel plate is as follows: (1) Casting process: the temperature is 1548°C after the vacuum is broken, and then the 33.4T flat ingot mold is used for casting, and the superheat is controlled at 40°C.

[0035] (2) Heating process: The heating process is as follows: according to the steel heating system of group II, the maximum heating temperature is 1239°C, the heating rate of steel ingots below 1000°C is 117°C / h, and the heating rate of ≥1000°C is not limited.

[0036] After the steel ingot is rolled into a billet, the billet needs to be heated and ...

Embodiment 2

[0041] Embodiment 2: This S355G10+N steel plate adopts the following composition ratio and production method.

[0042] The thickness of the S355G10+N steel plate is 130mm, and the composition content is (wt): C 0.08%, Si 0.48%, Mn 1.40%, P 0.014%, S 0.004%, V 0.060%, Nb 0.022%, Al 0.020%, Ceq 0.40 %, Pcm 0.19%, the rest is Fe and unavoidable impurities.

[0043] The production method of this steel plate is as follows: (1) Casting process: the temperature is 1546°C after the vacuum is broken, and then the 31.4T flat ingot mold is used for casting, and the superheat is controlled at 30°C.

[0044] (2) Heating process: According to the steel heating system of group II, the maximum heating temperature is 1231°C to ensure that the ingot is evenly burned through; the heating rate of the steel ingot below 1000°C is 109°C / h, and the heating rate above 1000°C is not limited.

[0045] After the steel ingot is rolled into a billet, the billet needs to be heated and rolled again in the f...

Embodiment 3

[0050] Embodiment 3: This S355G10+N steel plate adopts the following composition ratio and production method.

[0051] The thickness of the S355G10+N steel plate is 110mm, and the composition content (wt) is: C 0.10%, Si 0.35%, Mn 1.55%, P 0.010%, S 0.003%, V 0.045%, Nb 0.030%, Al 0.033%, Ceq 0.40 %, Pcm 0.19%, the rest is Fe and unavoidable impurities.

[0052] The production method of this steel plate is as follows: (1) Casting process: the temperature is kept at 1540°C after vacuum failure, and then cast with a 28T flat ingot mold, and the superheat is controlled at 20°C.

[0053] (2) Heating process: according to the steel heating system of group II, the maximum heating temperature is 1238°C, the heating rate of steel ingots below 1000°C is 112°C / h, and the heating rate of ≥1000°C is not limited.

[0054] After the steel ingot is rolled into a billet, the billet needs to be heated and rolled again in the furnace; the heating coefficient of the billet is 20min / cm, the maxi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com