Titanium alloy with matched high strength and toughness and preparation process of titanium alloy

A titanium alloy and high toughness technology, applied in the field of titanium alloy and its forming process, can solve the problems of difficult forming of forgings, achieve the effects of improving strength and toughness, optimizing plastic rheological characteristics, and increasing tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

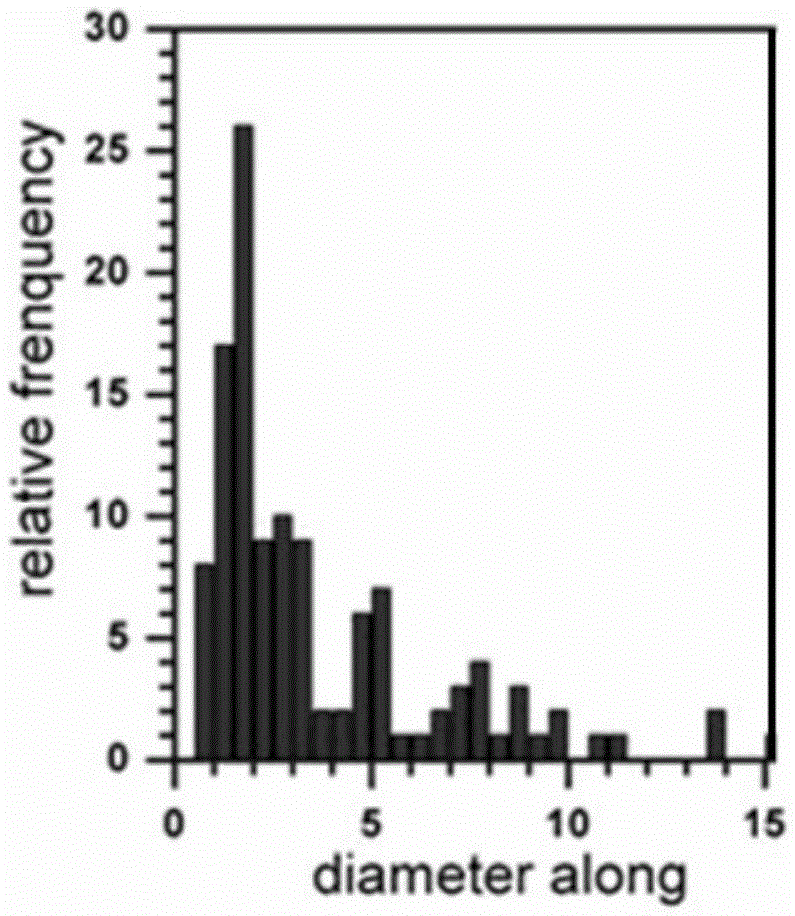

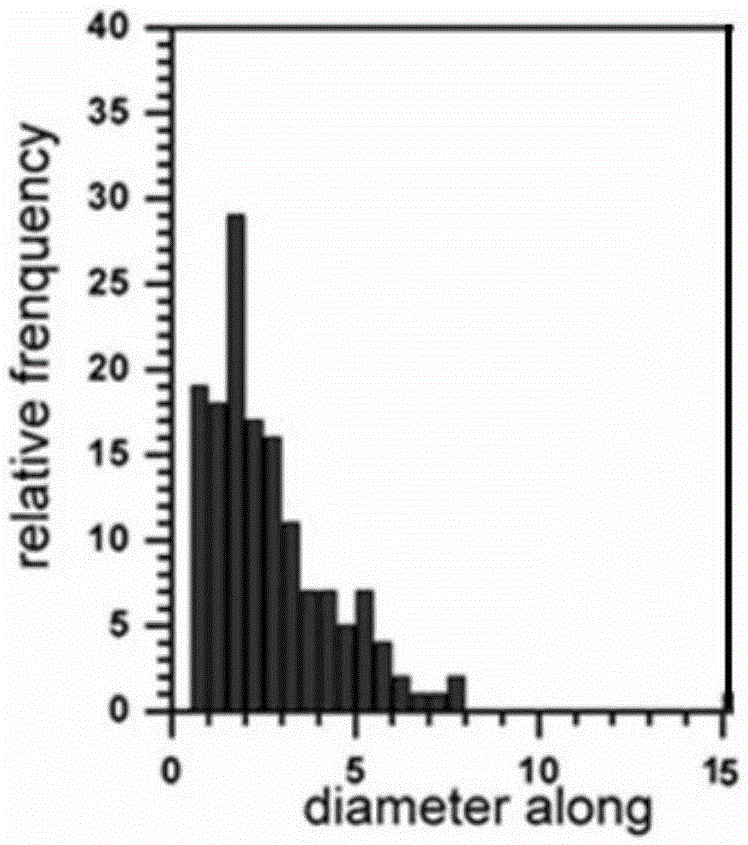

[0043] In Table 1, Ti-Al-Sn-Zr-Mo-Cr-V-Fe-O alloys numbered 2#, 4#, 5#, and 9# have obtained strength and toughness through solution aging heat treatment. better match. It can be seen from Table 2 that the tensile strength of the above four-component alloy is greater than 1100MPa, and the fracture toughness is higher than 80MPa 1 / 2 .

[0044] In Table 1 and Table 2, the alloys numbered 2#, 4#, 5#, and 9# have obvious advantages in strength and toughness matching compared with TC4 alloys, and the alloys of 2#, 4#, 5#, and 9# The fracture toughness value of the alloy is equivalent to that of the TC4 alloy, and the strength is increased by about 100-200MPa, which can obtain obvious structural weight reduction effect under the premise of ensuring safety and reliability.

Embodiment 5

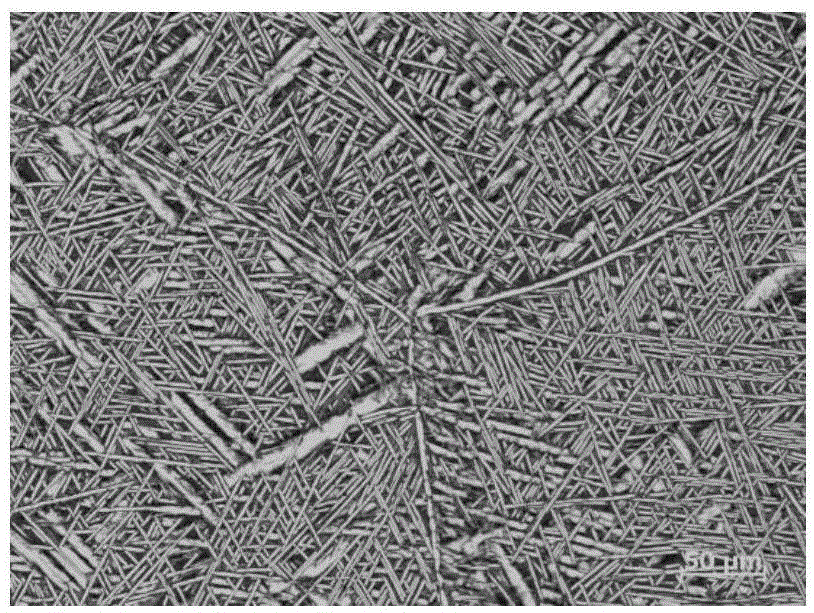

[0061] The specific preparation examples of high-strength and high-toughness titanium alloy forgings in this embodiment are as follows: including components selection, electrode pressing, ingot melting, ingot blanking, bar or plate forming and other processes.

[0062] 1) Alloy ingredients are distributed according to the following target components. The weight percentage of each constituent element is: Al: 5.8%, Sn: 2.1%, Zr: 2.0%, Mo: 3%, Cr: 1%, V: 1%, Fe : 0.16%, O: 0.15%, other elements such as C, N, H, Si and other elements are impurity elements, the weight percentages are all less than 0.1%, and the balance is Ti.

[0063] 2) Electrode pressing: finalize the ingredient list through composition design, selection of master alloys, and calculation of the ratio of different master alloys, and complete electrode pressing on a hydraulic press according to the ingredient list.

[0064] 3) Ingot smelting: After three times of vacuum self-consumption or plasma cooling furnace, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com