Hole-reaming forming technology for internal and external specially-shaped surfaces

A technology of hole forming and special-shaped surface, which is applied in the direction of manufacturing tools, forging/pressing/hammer devices, forging/pressing/hammering machinery, etc. It can solve the problems of increasing machining time, affecting the comprehensive performance of forgings, and cutting off the fiber structure of forgings. , to achieve the effect of avoiding bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

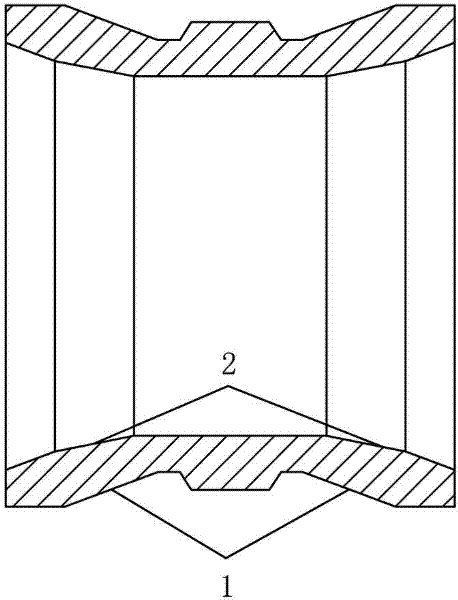

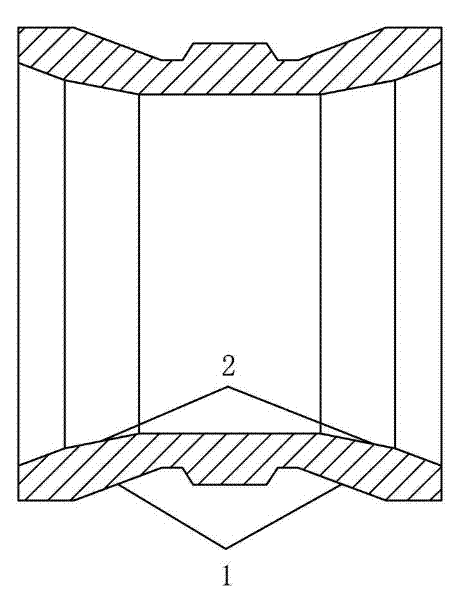

[0023] to process as figure 1 Shown inside and outside special-shaped surface class forgings are example, implement the process step of the present invention as follows:

[0024] (1) Forging design: design a symmetrical forging shape (as attached figure 1 ).

[0025] According to the asymmetric deformation characteristics of a single forging, we designed a symmetrical forging structure, that is, two-piece continuous forging, and considered the influence of the severe deformation area, and designed it at the connection of the two pieces.

[0026] (2) Design and production of tooling equipment:

[0027] Design and manufacture of anvils: design corresponding reaming anvils according to the external shape of the forgings.

[0028] Core horse bar design and manufacture: design the corresponding core horse bar according to the inner surface shape of the forging, the shape of the core horse bar is the same as the inner surface shape of the forging, and manufacture it.

[0029] (3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com