Pipe-expansion mold

A tube expansion and mold technology, which is applied in the field of molds, can solve the problems of tube expansion efficiency drop, influence on coaxiality, low elongation, etc., and achieve the effect of ensuring tube expansion at one time, increasing propulsion speed, and reducing tube expansion time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing, the present invention will be further described:

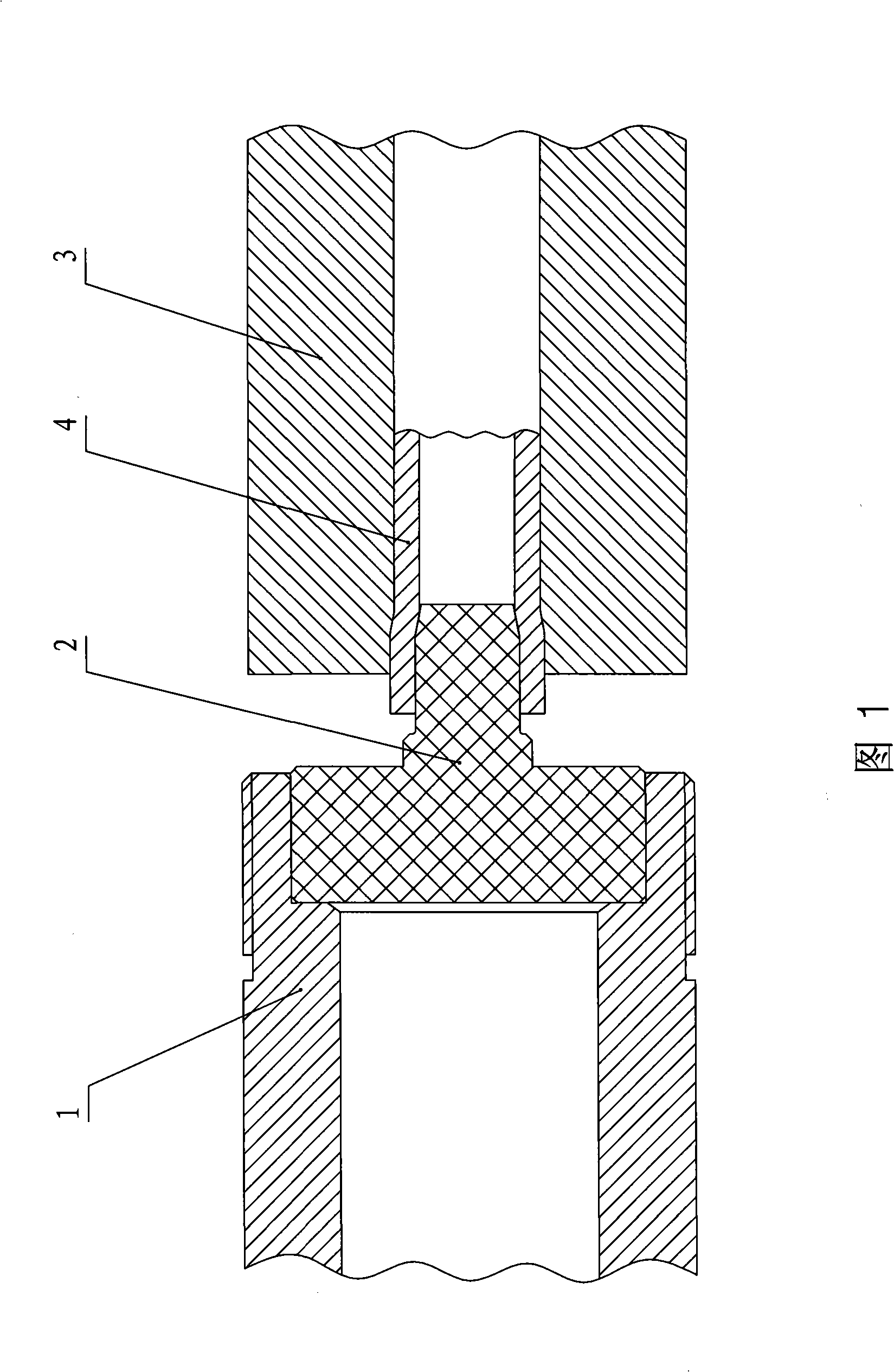

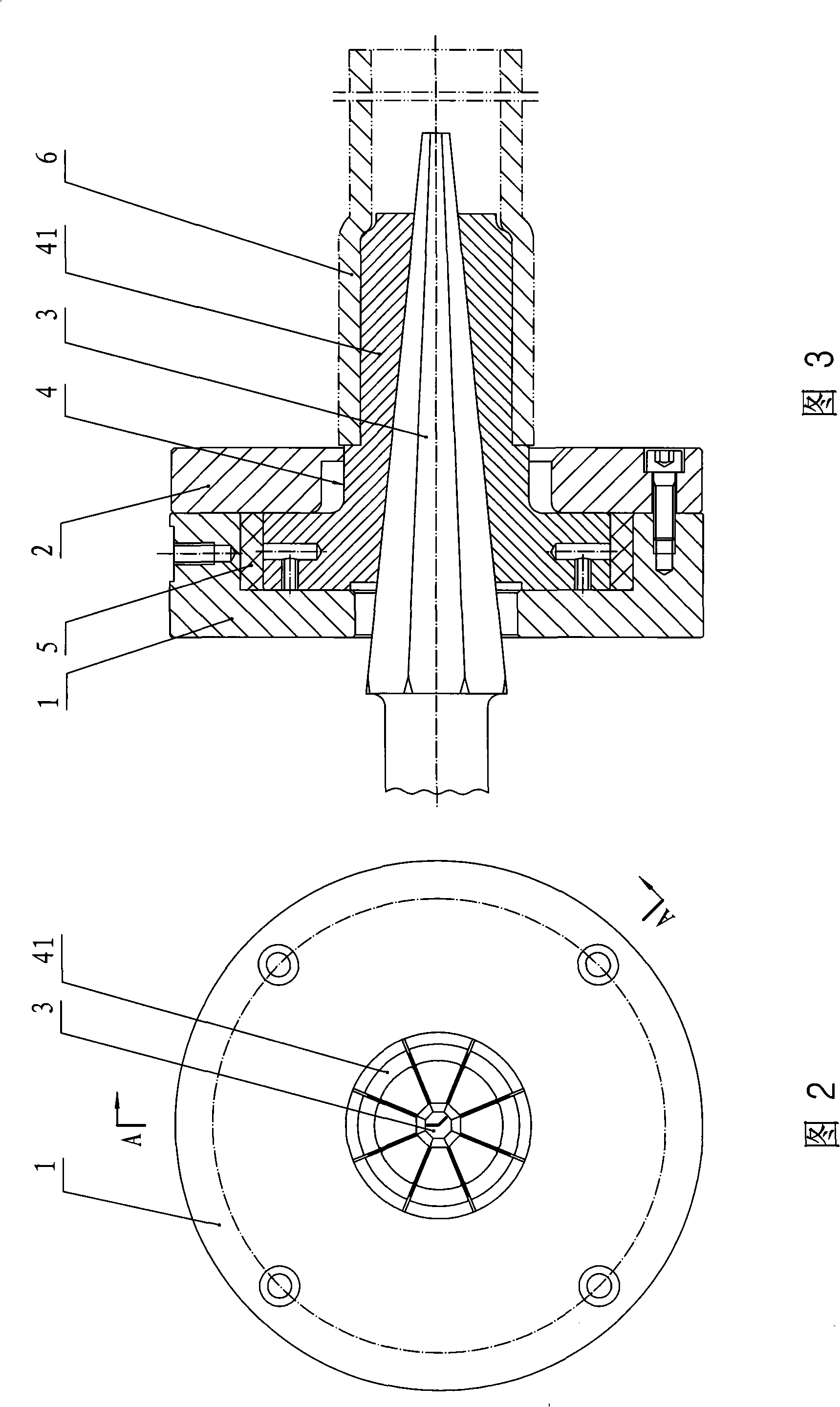

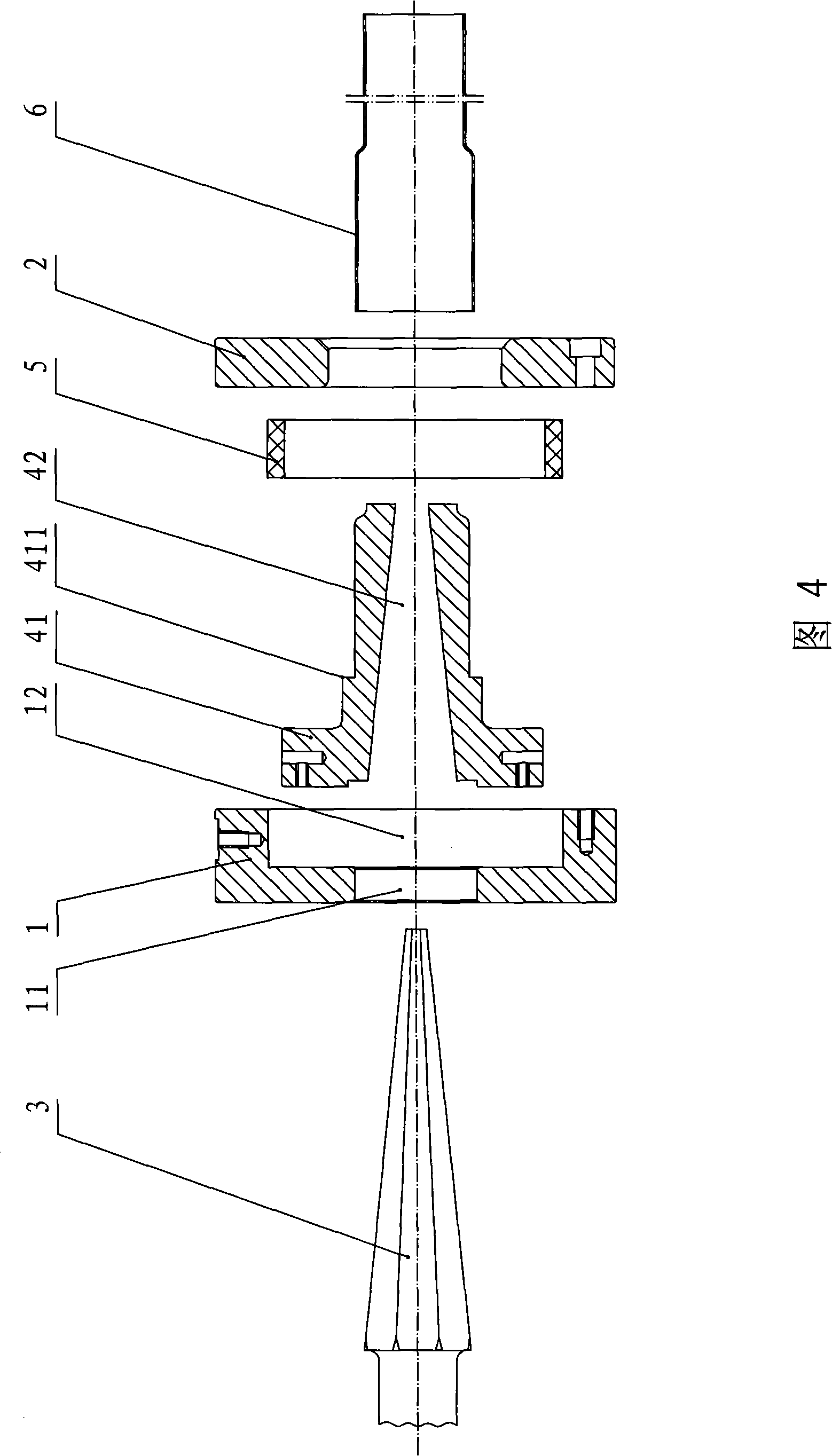

[0018] As shown in Fig. 2 to Fig. 5, a pipe expansion mold according to the present invention includes: a mold base and a pipe expansion mold, and the mold base includes: a mold base body 1 and a cover plate 2, and the mold base body 1 The two sides are provided with the guide hole 11 and the working hole 12 which are connected with each other. The tube expansion mold includes: an octahedral cone-shaped mandrel 3, an elastic washer 5, and eight pieces on the outer wall of the mandrel 3 with eight inner walls respectively. The expansion tube body 4 formed by the expansion tube monomer 41 that the two inclined surfaces match together makes the eight inclined surfaces forming the tapered hole 42 in the expansion tube body 4 match with the eight inclined surfaces of the mandrel 3 outer wall respectively, and the expansion tube The bottom of the body 4 is sheathed with an elast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com