Manufacturing method of graphene device

A production method, graphene technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., to achieve the effect of avoiding influence and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

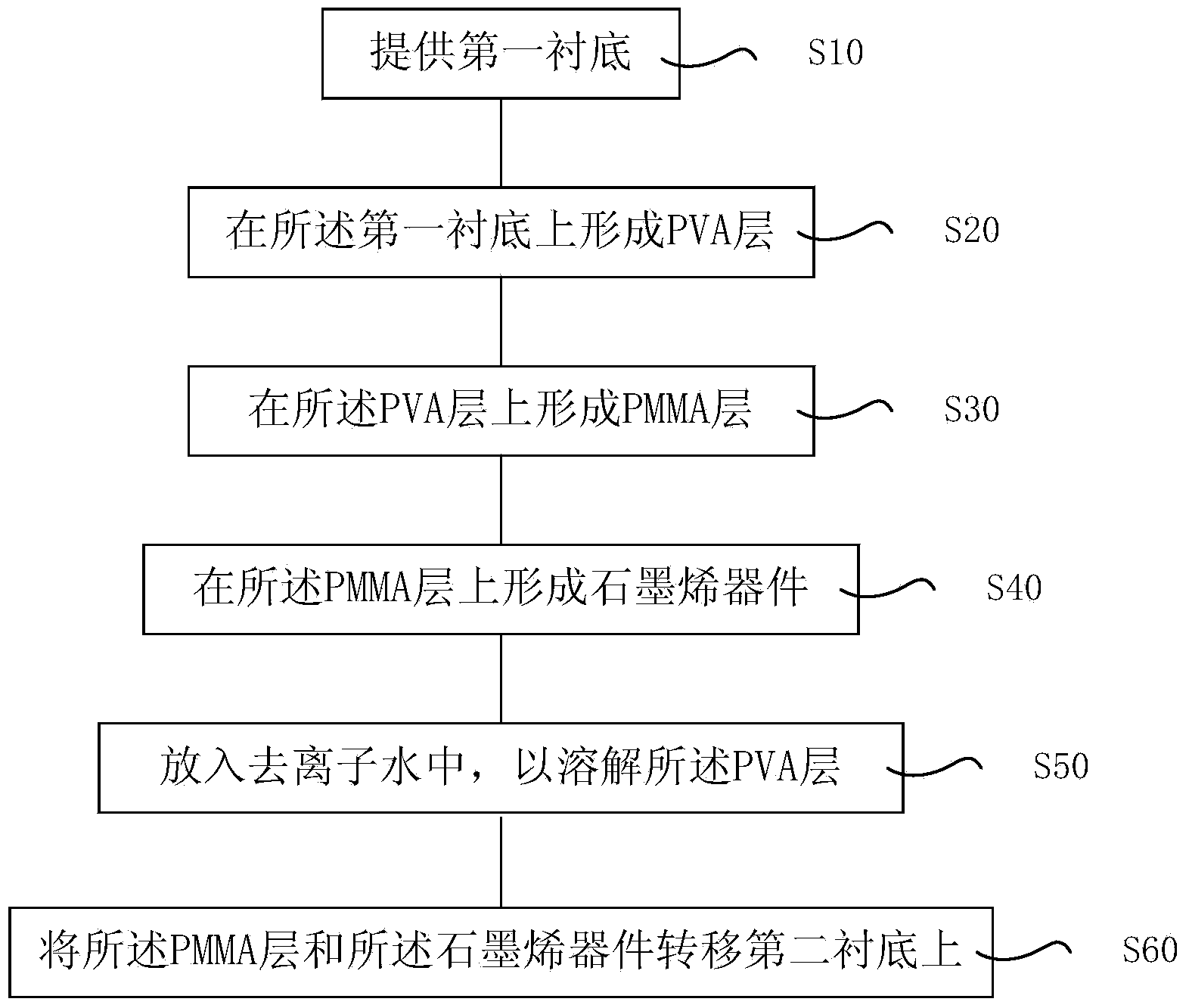

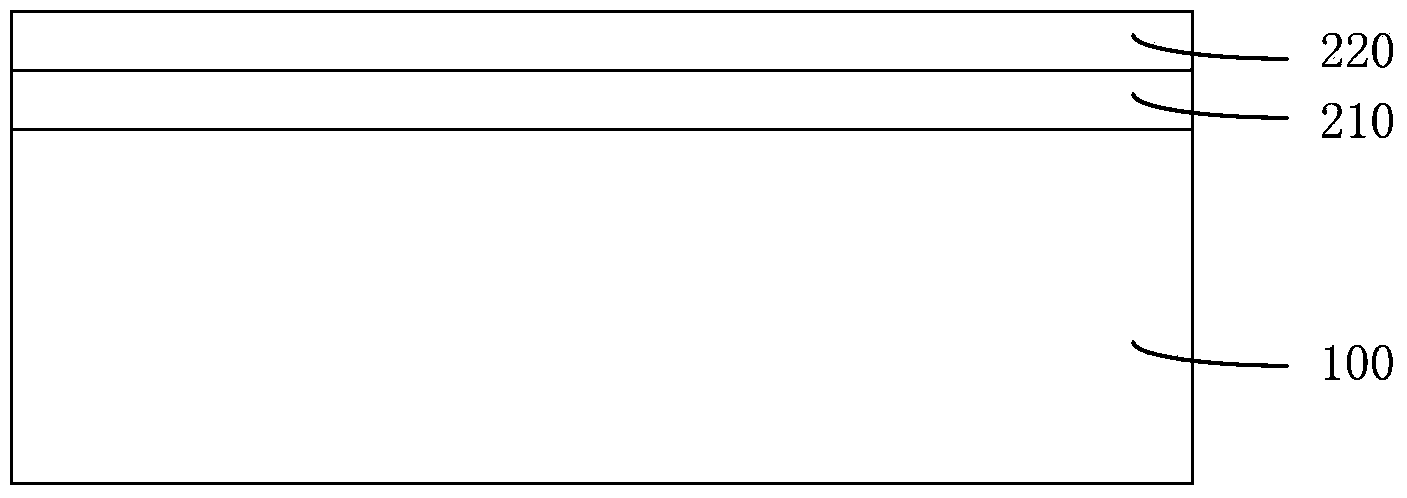

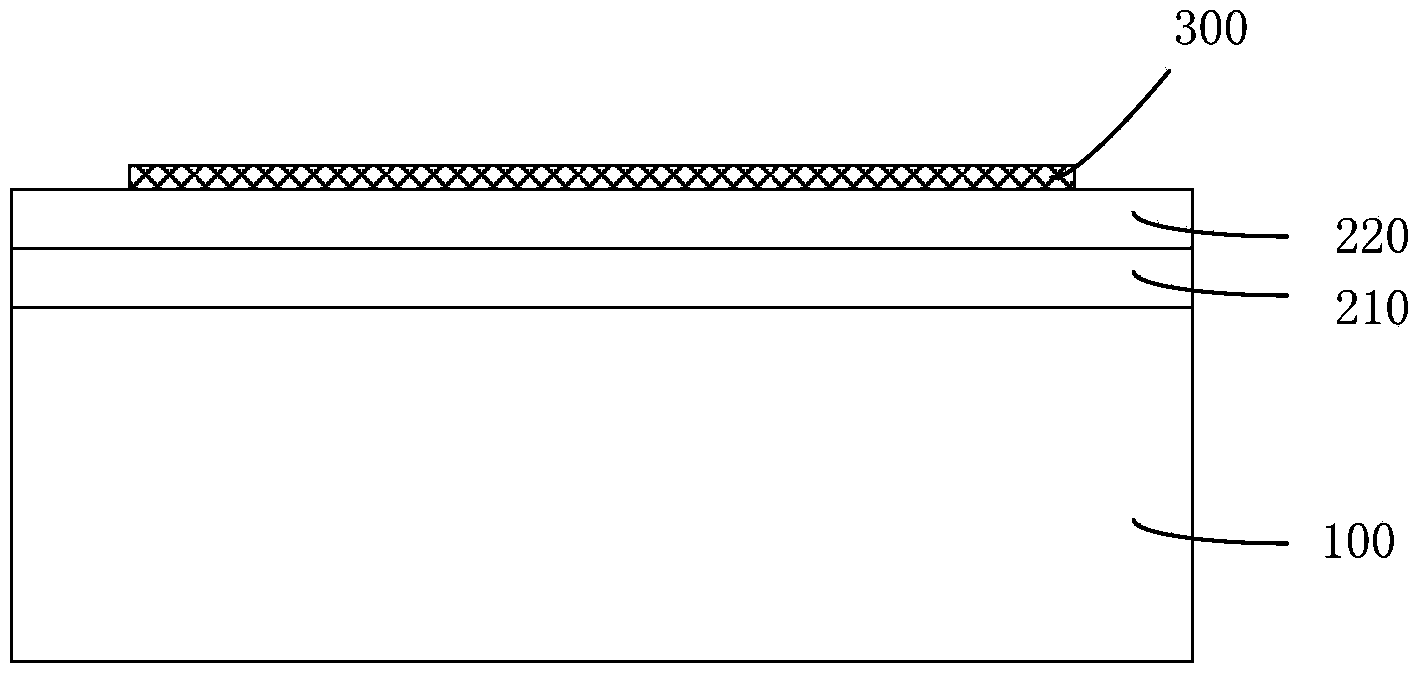

[0039] The present invention will provide a kind of manufacturing process of transferable graphene device, at least comprise: form PVA layer on described first substrate; Form PMMA layer on described PVA layer, prepare graphene on described PMMA layer device, then dissolve the PVA layer, transfer the graphene device and the PMMA layer together to the polyimide substrate, realize the formation of the graphene device on the flexible polymer substrate, and the device switch ratio on the flexible polymer substrate can reach 10 -6 , the device can still work normally after repeated bending.

[0040] In addition, the present invention is also applicable to transferring the prepared graphene device to other substrates, so as to realize the improvement of the function of the graphene electronic device and its wider application.

[0041] Embodiments of the present invention are described below through specific examples, and those skilled in the art can easily understand other advantag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com