Method for forming metal wire through resistance and electromagnetic induction composite heating

An electromagnetic induction and composite heating technology, applied in the field of metal parts forming and processing, can solve the problems of inability to ensure smooth transition and forming of wire, long heating time, poor tissue properties, etc., to reduce investment and maintenance costs of equipment, and improve utilization. rate, the effect of reducing heat input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

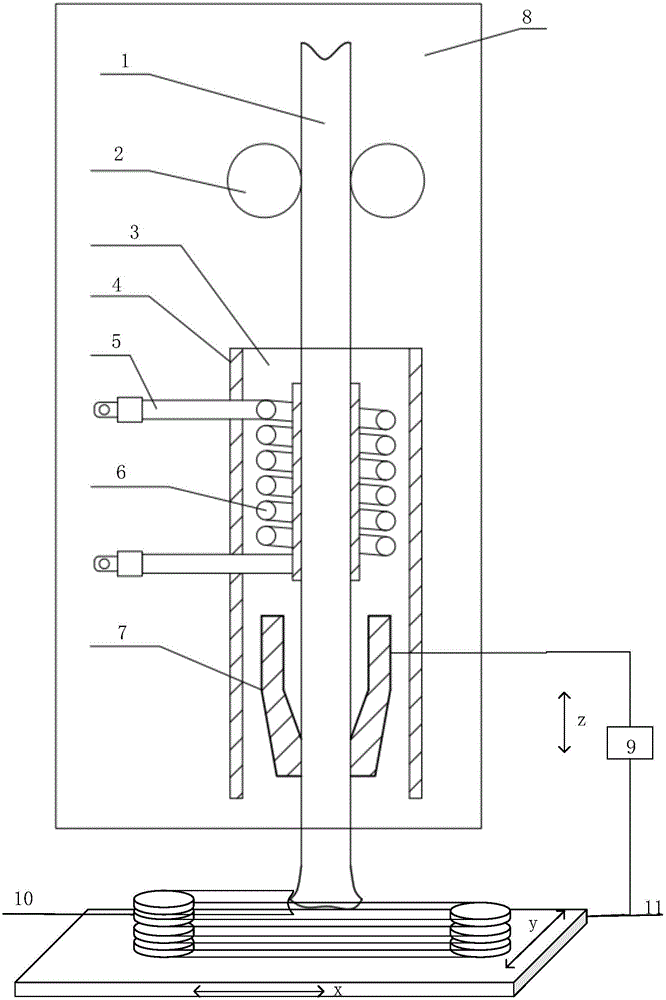

[0034] The equipment used in this embodiment includes: an electromagnetic induction power supply 5 , a programmable power supply 9 , a pulsating wire feeding system 2 and a three-dimensional motion control system 8 . Its electromagnetic induction power supply 5 and programmable power supply 9 are heat sources, the electromagnetic induction power supply 5 is crystal type high-frequency induction heating equipment of the XJH-25KW-B model, and the programmable power supply 9 is a special self-made power supply. One end of the programmable power supply 9 is connected to the substrate, and the other end of the programmable power supply 9 is connected to a conductive tip. The pulsating wire feeding system 2 is composed of constant speed wire feeding, buffer and pulsating wire feeding. The three-dimensional motion control system 8 is controlled by the motion track set by the computer. Metal wire 1 is a Q235 low-carbon steel welding wire with a diameter of 1.2mm, and the base material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com