Precision isothermal forging combined die for complex aerospace die forged pieces

A technology of isothermal forging and combined dies, which is used in manufacturing tools, forging/pressing/hammer devices, forging/pressing/hammering machines, etc., and can solve problems such as difficulty in realizing ideal forging products, difficulty in forming forgings, poor universality of molds, etc. , to reduce the weight of precious materials, improve mechanical properties, and reduce weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

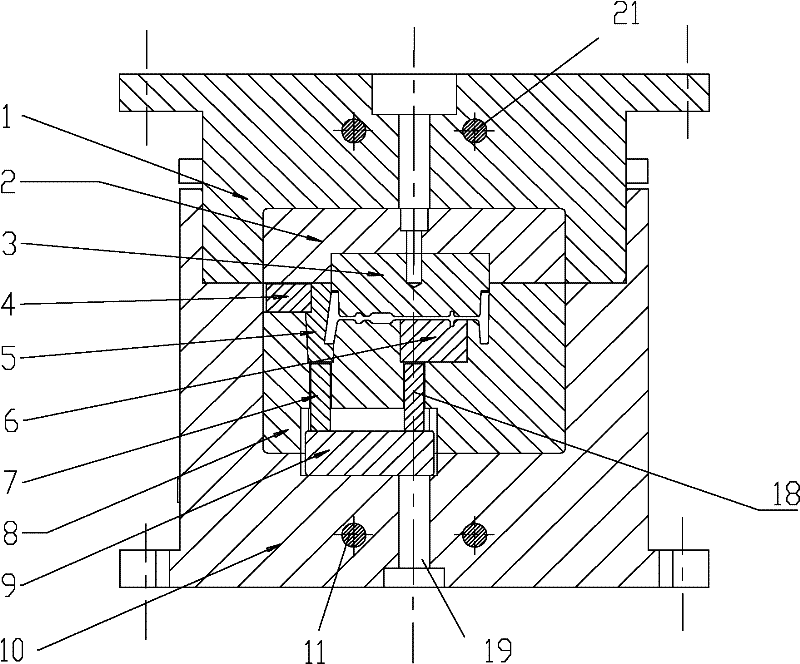

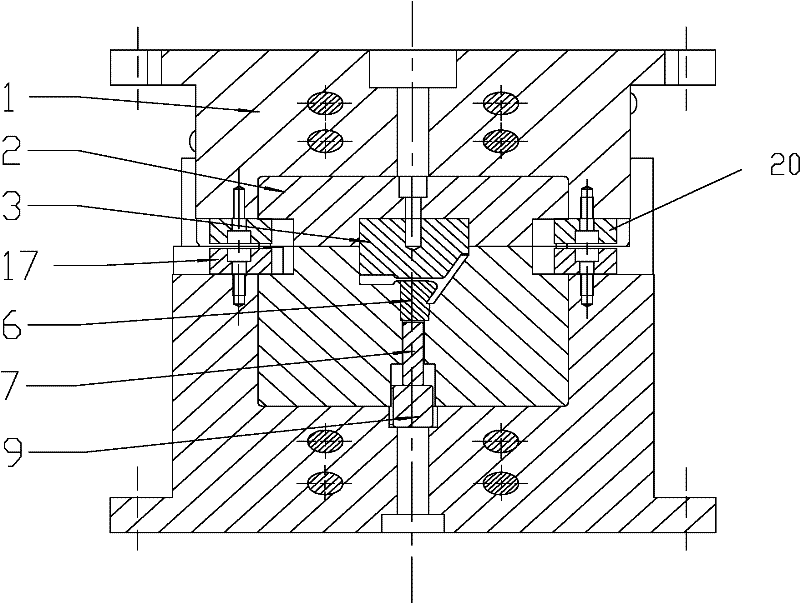

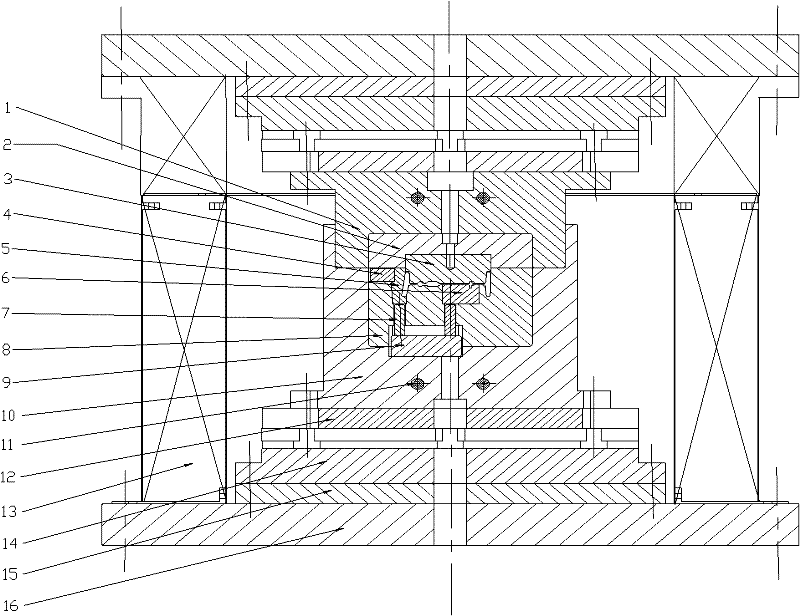

[0020] see figure 1 and figure 2 , the structure of the upper mold is that the top of the upper mold seat 1 is provided with a step for fixing on the press pad, the upper mold seat 1 is cylindrical, and the upper mold inner sleeve 2 is fixedly installed on the upper mold seat 1 with the upper pressing plate 20 Inside and flush with the boss of the upper die base 1, the upper die inner sleeve 2 is a cylindrical structure, the material is general forged steel, the upper die insert 3 is the upper model surface, and the bottom surface is square, which is made of high temperature resistant materials. , the upper die insert 3 adopts interference fit and is fixed in the upper die inner sleeve 2 by bolts; the structure of the lower die is that in the lower die base 10 there are two steps, one upper and one lower, the upper steps are positioned and conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com